Question

What is the best CAD program to produce fully dimensioned custom elevations and plan views to build from? We co not have CNC machinery, nor do we plan to. We would like to be able to produce CAD shops that have a similar look to hand drawn shops with the ability to be truly custom. We do a small amount of radius work and are face frame only.

Forum Responses

(CAD Forum)

From contributor D:

It depends upon what exactly you want to do and how you want to do it. I did a bunch of web searches and looked at options and reviews of different projects. I started out with DesignCAD 3D. I got it to do 3D drawings, but I've ended up using it for shop drawings - and once I learned it (they have instructional CDs), it's a breeze to whip up drawings - I just have to figure out dimensions. I use keyboard shortcuts and that works well for me. For presentation drawings, I use eCabinets (I haven't pressed it into doing cut lists yet - still learning the ins and outs, so I don't trust my settings to crank out correct cut lists. For cut lists I use CutLists Plus, which I really like. We almost exclusively do face frame cabs, as well as many non-cabinet types of projects (outdoor arbors, etc).

3d modeling is nice, but if I spent 30 hours on contributor P's drawing (we don't need 3d models, so the situation is probably different for you - this isn't a slam), my boss would skin me alive. Something like that should be able to have shops made in about 8 hours or so at most, depending on the skill of the draftsmen. That's for 2d shops, full sections, etc., not 3d models.

I have modeled similar things in Ashlar Vellum 3-d wire frame and in Solidworks and I would say 30 hours is pretty good.

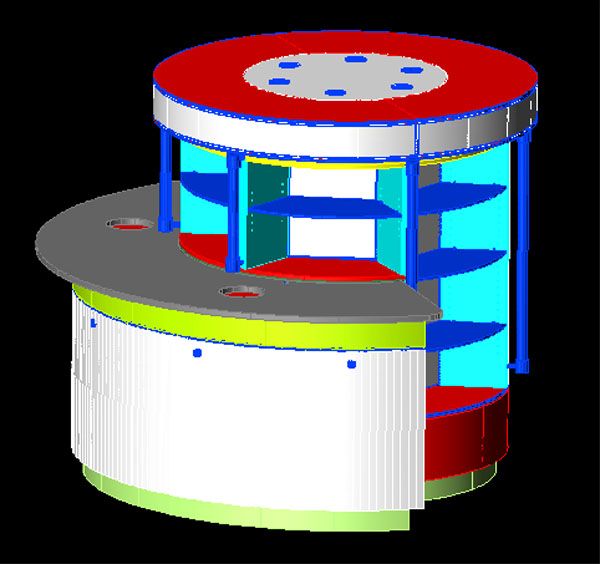

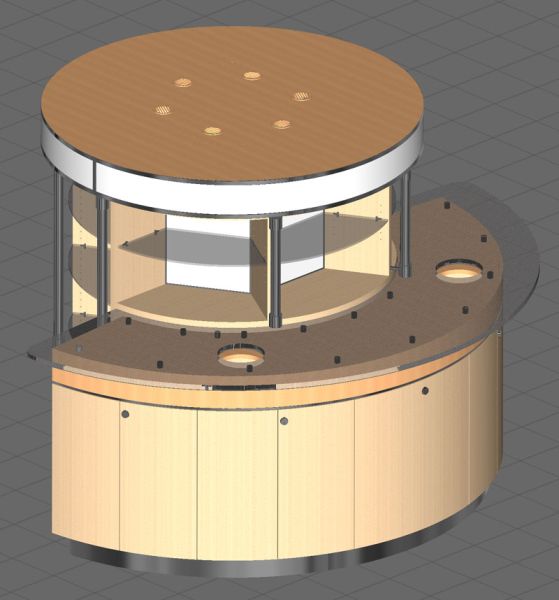

What he has here is an engineered (this means thought through for workability) model with the parts visually checked, assembly holes placed (correctly) and all the parts (including various materials) drawn with holes and ready to go to CNC and at least 8 pages of detail drawings in 3d and 2d. In effect, he has done in the computer what the bench man would usually do on a prototype.

Is this worth it? It depends. If you were only doing one of these, I would say you are correct - draw it as best you can in 2d and let a skilled (scarce these days) bench man do the rest. If you are doing multiples, then modeling is the way to go.

I could have drawn it in 2D also and it would have taken a lot more than 8. In the end it does not really matter. I think you missed the point. 30 - 8 = 24. That's the difference in time. The shop will finish my unit more than 100 man hours sooner than yours and I know for sure my unit will be correct. There will be no wasted materials from mistakes, less accidents and the customer, Federated, says the drawings are the best they have ever seen. They were so impressed they sent that exact set to all of their in-house draftspeople, stating, "This is the way shop drawings should be done!" That part matters too because they will give us more work. Hey, they actually offered me a job.

I used to draw in 2D too. I have found this method to produce the best bottom line results across the board in the end. I can figure it out much faster on the computer in 3D than they can looking at 2D drawings in the shop. I can also render it when necessary.

As for the time to finish, you're probably right - your shop will finish faster than his, but I also imagine you are using CNC and nesting software, which he said he is not looking for. If you and I were to both give him a set of drawings, and he was not using the nesting and CNC features, he would probably get it built in a pretty similar period of time. If he were to try and use the software, being he is familiar with 2d drafting on paper, he would probably have an easier time grasping a simple drafting program. The point is not to debate the effectiveness of 2d lines vs. 3d models - 3d takes it every time as far as capability, but it still does not make it a wise first choice. It's like using unigraphics to make running trim drawings - sure it will work, but why would you? It's the howitzer to hunt rabbits thing.

The final point. Yes, you can figure it out on a computer, but the guys in the shop still have to build it, and if all they have is a 2d shop drawing, then all the rest is fluff, and the money paid for that capability is wasted. If you are doing generally straight box work, like this guy seems to be, 3d is a tool that will give him a limited return, if he can get a natural feel for how to use it. He most likely can with 2d; with 3d it's a gamble.

We do not have a CNC route either. I can still send it to CNC if I find a shop to cut the parts and exporting what they need to cut is automated. Either apples to apples, I am going to beat the 2D process by 100 hours easy. CNC or not. I can do face frame construction.

I understand your blow and go need for drawings. Many shops require that. Many of those bill for the 2D drafting time and use that money to buy the material for the project. This is not his case, though. He asked for a set of drawing to build from. He can take a look at the drawing and get some ideas. If the shop has a question on detail that I did not produce a detail for, they can always look at the model on the computer.

We all have different ways of doing things. I just hope that what I provided will be helpful in seeing one part of the full picture.

They will send you a free demo CD that will show you what it can do. Even if you don't currently have AutoCad, the demo will show you the quality and speed that is possible. It is very reasonably priced.

I knew nothing about AutoCad before I purchased the program and with one day of tutoring and a few followup questions on the phone, I was good to go. Also, anytime I have a stupid question, the guys are ready to help me. It cost nothing to take a look and it just might be what you are looking for.

Design Cad 3d Max gives you the ability to draw any line, any arch, and dimension anything you want precisely, and add text anywhere.

As for a hand drawn appearance, I have ADT2004 (parametric features) and it will allow me to produce the appearance of 'hand drawn' files for print and export. Acad 2007 will also produce this type of file. It really can improve the appearance of a model for presentation, though I would not send that file to the shop to be built from.

Check out the software on Autodesk, download a 30 day evaluation and give it a try. Many manufacturers will provide software and blocks for their parts that allow you to add the correct location of hinges and glides to your drawings, saving calculation times. Plus, when you do have work that requires CNC machining, send your 2d or 3d plans to the shop and parts can be machined for you.