Question

After applying finish to one of our guitars and sanding down the top/back, we noticed small white specks on the top of the guitar. We use automotive clear (poly). The top is flame maple while the back is mahogany. The headstock is the same wood/stain as the maple top.

There are small white specks on the top wood, and they are each perfectly round and randomly spaced. They are so small you can't see them unless you look very closely. The headstock which is the same wood/stain doesn't have this problem. They were not there before we started level sanding the body. The back of the guitar (mahogany side) doesn't have that problem. In fact, it's perfect.

We think that the specks are caused by the sanding (dust being ground into the pores). I tried sanding more to get them out, but they will not move. It seems that when I sand, the specks stay there and just get ground down with the finish around it.

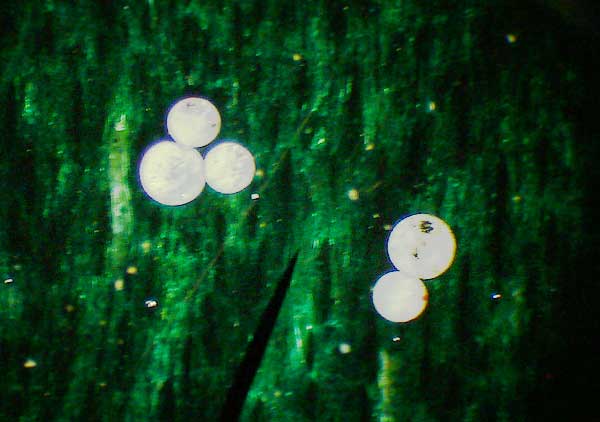

I need to know what they are and how to get rid of them. The last image below is of the dots under the microscope (approx. 80x). As you can see, they are round and nowhere near the size of the wood's grain. They are about the size of the tip of a needle.

Forum Responses

(Finishing Forum)

From contributor H:

Because they are round I believe they are air bubbles that have popped and now are craters being filled by your sanding dust. The perfect spherical shape does not lend itself to being else.

The main reason I say use one made specifically for wood is because of technical support. I know a lot of folks that use automotive clears on wood and do just fine. I just can't justify the cost, as most of the urethane clears I've priced were around or over $100 a gallon. The problem is the solvent is trying to flash off but the surface has cross-linked forming a film barrier, so bubbles form. When you sand them, they pop leaving a crater. Grind them down, find something you can add to the automotive urethane to slow down the evaporation rate some, you should be in business.

Cause: Finish skins over before all of the solvents have evaporated which traps little bubbles of evaporated solvent in the finish.

Fix: Use a slower retarder/hardener, keep your wet coats less than 4 mil, and don't spray in a hot, drafty environment.

Some causes are heavy coatings, applying your coats to fast, having the second coat delaying and trapping the bubbles in the first coat. Damp woods, woods that were stripped, stains that are not dry, moisture in the air lines and the materials are all possible causes.

Comment from contributor A:

I agree- look like air pops thru clear coat. I will try to give mechanism of these - either due to moist substrate, or too fast application of color coat between the coats, air is entrapped which wants to get out. Color coat is somewhat porous but clear is not. If it starts gelling before air gets out, then basically bursts out of the CC layer and looks like a bubble or pop. Prevention - dry and clean the substrate well, apply BC coats slowly with adequate flash time and don't apply too much clear.