Question

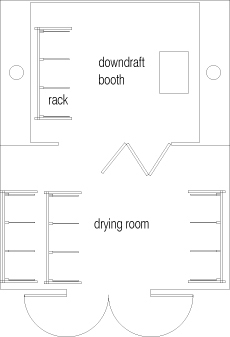

I have a 20'x17' 1 hour rated enclosure that I would like to dedicate for finishing. The space is separated from the wood shop by a floor to ceiling partition so dust will hopefully not be a problem. I am currently considering a 10'x17' downdraft booth to sit within this room. Until I can afford the heated make-up air unit, I would like to draw air from the 6' high by 50' x 50' plennum space above the booth. I finish 90% of my goods flat and then stack on a rack to dry. The parts would be stacked on a hafele style rack in the booth until the rack is full and then rolled out into a ventilated drying area while the next rack is rolled in.

I have several questions about this setup.

1. Will the finish of the freshly painted parts sitting in the booth suffer from too much air flow? With a cross flow setup sometimes you get orange peel if you leave a panel in the air flow stream.

2. How can you control the cleanliness of the air being pulled from above? Are filters alone sufficient?

3. Is a downdraft booth really going to be superior to a cross draft booth like my supplier claims?

(Finishing Forum)

Forum Responses

From contributor G:

I'm envious. A couple AAAs in there and you'll be ready to rock. I have worked with a similar setup. We were doing 80-90 pieces/shift, stained and lacquered, one finisher/shift.

My opinions:

1) Yes, but you will find a place where the draft is less to put your rack.

It is the flash off period that you need for your best flow out potential. It is too bad that some air booth manufacturers and their consultants do not seem to take this into account and it is even worse when a shop owner is standing in the way of a potentially good finishing operation setup.

Recently I was hamstrung in a booth/make up unit (with heated air) that was so poorly designed and set up that all the booth could do was take away my overspray. My finish was as rough as the sandpaper it was scuffed with. What was really unfortunate was that this was a setup that was only a few years old and cost $80,000. No thought at all was given to flash off.

It seems that no thought at all was given to how to do any flashing whatsoever because the vent stack leaked and poured from day one whenever there was any rain. At least the fluorescent lights were set properly and I could see what I was spraying.

2. You need a different type of filter for supply air. Search for AJ Dralle Company for information. Supply filters clean the air coming in, but also are important for air diffusion, which goes back to your first question. When air supply isn't diffused properly, you could have problems with turbulent air flow. I actually had this problem in my own booth because I was trying to use a simple furnace type filter to clean my supply air. Using a wind gauge across the face of my booth, I had very inconsistent air speed and pockets of turbulence. When I installed the Dralle supply filters, the problem went away.

3. I have a cross draft booth and have never used a downdraft, so I can't compare firsthand, but I would seriously question the cost/benefit. I'm going to guess a vast majority of finishing shops are using cross draft and doing just fine.

Final note: You really cannot do enough shopping around and research on this decision. Above all, it is critically important to have a rep/supplier with many previous installations experience, who is going to be available to work through every issue from planning to installation and configuration and then long after the sale. Air handling and controlling air flow for professional setting is a complex issue.

A down draft may solve some problems for you but consider that there are thousands of accomplished finishers working with cross drafts every day and getting the results they need. Too much air flow during flash is definitely a problem.

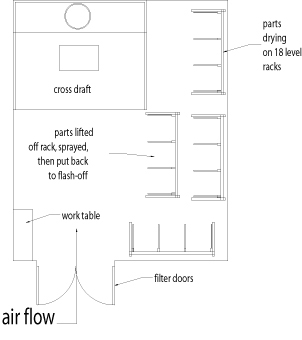

Weigh the costs of make up air against every other bell and whistle you can think of to make the overall finishing operation top notch - mixing stations, agitators, circulating fluid heaters, tow carts, IR heat lamps, down draft tables and etc. Essentially if the parts are warm (in the drying room) move to the cold booth and are sprayed and move back to the drying room (warm and relatively still, some exhaust to gently help pull the solvents which fall to the floor out of the area) then you achieve a great finish. We spray all the MLC post cat products using the setup described above and never have environmentally related problems.

If you need a really scientific approach then consider every single procedure which acts upon a part from the time it enters the finishing area until it leaves. Evaluate the cost to benefit ratio of each point of value addition. You will conclude in a rational fashion what the optimal budget is for these specific tasks in a defined time frame.

It's beside the point, but since you also mention the use of an explosion proof motor, this is not required for a belt driven tube-axial fan of the type normally used in a spray booth. The motor and belt drive is completely sealed away from the air flow on this type of fan, hence ODP or TEFC motors are fine.

As a general comment I might also add that it is a common misconception that it is ok to use fans with exposed motors in the spray booth as long as it is an explosion proof motor. The explosion proof rating is for vapors or fumes, and is specifically not rated for any application where dust or overspray can accumulate on the motor.

Of course it is done without air makeup all the time, but you put up with a negative pressure situation that causes all sorts of problems and sometimes very serious consequences result. Ideally, you want the supply air to be a little more than the fan requires so the room is pressurized a little to the positive, and that helps keep the dust out. If you filter the supply air though, this is going to catch the most of the dust.

However, if you use a good supply air filter/diffusion media such as the Dralle filters they will restrict the flow of free air quite a bit. That's what you need in front of an air makeup unit, but if you are relying on free-air supply it will add more to your negative pressure in the room. I don't know what it is and I'm sure any HVAC person can tell you - but you need to find the calculation that will tell you how big the opening needs to be on the supply end that will provide the cfm that fan needs - and then account for the static pressure increase when you filter it.

From contributor S:

Width x Height of your booth opening gives you the minimum cfm exhaust necessary. The depth of the booth from the face to the filter wall does not factor in the calculation. Sorry, I was keyed in on your dimensions you gave in the first post, but I studied both drawings again and I think I see it more accurately now.

Your room is 17x20, so it looks like in the cross draft plan your booth "width" is actually the 6'. The depth of the booth looks to be 10', but this dimension doesn't matter in the equation. Again, it is width x height = cfm exhaust needed.

More than likely your booth is a 7 or 8' height. Say for example it is 8' high and 6' wide - that would mean you need a fan capable of exhausting at least 4800 cfm.

I will repeat again, this is only the minimum. You'll probably need at least 5500 cfm to assure adequate cfm exhaust when you factor in static pressure variances. Clearly, this is going to be a lot more manageable than a fan sucking 3 times this amount as I earlier thought your were saying. Still, 5500 cfm is a lot of air.

Before you buy a filtered make up air unit to solve this problem perhaps someone on this forum, or a mfg (salesperson) can explain why a booth with cold, filtered air is a problem if the material is warm (lacquer) the parts are warm and the exposure time of the parts is minimal. Keep the parts warm in a drying room with controlled (low air movement) ventilation. Bring them into the booth, shoot them and return them to the drying room.

There is a lot of clean air outside that you can duct in, pick up your overspray and duct out. Don't fool around with trying to size you fan to the 100 cfm per square foot rule. The difference between a 6000 cfm tube axial fan and a 30,000 cfm tube axial fan (both with a belt driven, hazardous location motor, the application of a VFD to which voids your warranty and insurance in my part of NY) is under $1,000.

We need between 5,000 cfm and 9,000 cfm in our booth depending on what we're spraying (material, pressure settings, gun type, horizontal or vertical, large panels or small, size of over all piece etc.) Our fan is 42" in diameter and is running at about 20% capacity. Another nice thing about a big fan is that you can duct your clean, outside air in through a solid foot of filters and around a dozen elbows and from 200 feet away and the fan will over come the static pressure at the volume you need without working hard.

There are a lot of ways to get a good working booth but they will all share a set of common principles:

1. The booth exhausts adequately (nice to be able to change this parameter as needed).

2. The booth gets dirty right away and you start tracking this into the drying room.

3. The drying room should be able to get the parts warm before you shoot them.

4. The wet parts should flash with little air movement first.

5. The drying parts have their cure accelerated by heat and ventilation.

All you have to do is use cold air to move your overspray outside and warm air to dry your parts.