Spraying in Humid Conditions

Finishers discuss ways to adapt to hot, humid weather. October 18, 2005

Question

I live in the Northeast where it is very hot and humid right now. Does anyone have problems staining and topcoating in high humidity? If so, are there any precautions or solutions for the problem?

Forum Responses

(Finishing Forum)

From contributor L:

I'm in CT, where it's hazy, hot and humid. That's how the summers are. Since I've switched from Valspar to ML Campbell's pre-cat, I no longer have issues with humidity and blushing.

Things you can do or check:

Check your water trap and empty often.

Use a slower evaporating thinner or retarder to prevent blushing.

Use a de-humidifier in your drying room.

From contributor D:

Unless you're spraying in optimum conditions (as what's used in the formulation of materials), don't expect anything to be ready to spray out of the can. I'm in Vermont and the conditions are the same. The above are good measures of prevention. You can also try to keep your film build down on individual coats with reduction and retarding, possibly adding the need for one more coat of material. Reduction up to 20%? Retard up to 10%? You don't want it to stay open too long. Check with your supplier.

From contributor M:

Apply one coat at a time, then allow it to dry, before you apply the next coat. Try spraying in the early morning or in the evening, as it cools down. You also need to circulate the airflow. You have plenty of company with the same condition all around the country.

From Paul Snyder, forum technical advisor:

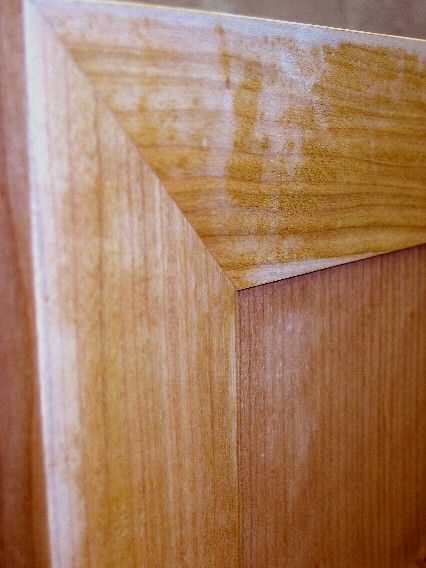

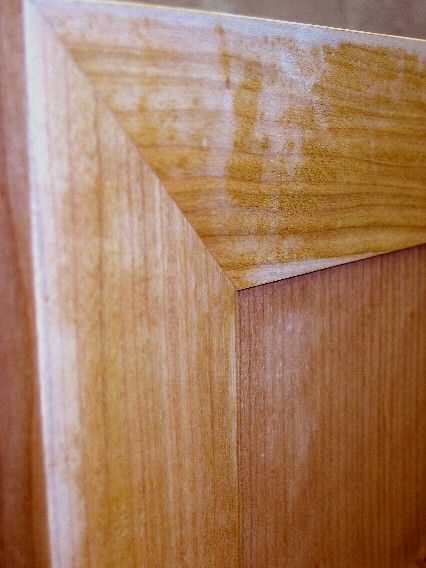

The humidity can cause some problems; oil-base stains and finishes dry slower and evaporative finishes like shellac and lacquer can blush. What kind of stains (fast dry or oil-base) and topcoats are you using? Here's an example of blush:

Click here for full size image

From contributor W:

Being in south Louisiana, we struggled with humidity and lacquer almost year round. I met with my SW rep and he got me to try conversion varnish. I was a bit apprehensive at first. It sprays very much like lacquer does except that it does not burn in. We have not used retarder and have had no blush since we switched to conversion varnish. I like it very much. It has made our finishing easier and better quality.

From the original questioner:

Thanks for all the input! I will be using Mohawk NGR and wiping stains with Star Sealer and CV.

From contributor W:

You might want to try samples from a couple of different manufacturers. Not all CV is created equal. Some brands take longer to dry than others. Also, you can skip the sealer. On most brands, the CV is self sealing and sands well. It saves having to do all of those changeovers. The CV builds so much better than the lacquer that in most cases we spray a base coat, sand and topcoat and that is it. On more porous materials like pine and MDF, it will take an additional coat.

From Paul Snyder, forum technical advisor:

You should not have any problems. Neither the dye or CV are adversely affected by humidity other than maybe a little slower flash-off time. Keep the air moving and you shouldn't have to slow down at all.

From contributor T:

Ditto on the CV. Been using it for 5 years now and no blushing. Be careful during cold season - one coat may need to dry as long as overnight if 60-70 F occurs.

From contributor O:

If you do get blush, you can shoot a wet coat of straight retarder over the piece. There's enough hot solvent to re-liquefy the resins, but the whole mess goes off slowly enough that the trapped moisture can escape. With a CV you'll have to get right on it, though, before too much crosslinking occurs. The technique works like a charm, but on one occasion there was so much solvent sitting on the veneer and for so long that it dissolved the glue line and instead of a grey, flat cloud, we ended up with a clear, round bubble.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor G:

We are located in Winnipeg, Canada and we’ve found that if you turn the heat up in the house it stops the wood from turning milky. We use lacquer thinners on a rag and wipe to get rid of the milky-like substance if it occurs.

AI enhanced answer (added Jan 27, 2025):Spraying finishes in humid conditions can be challenging due to slower drying times and potential for blushing or uneven finishes. Here are some tips:

1.

Choose the Right Finish: Opt for finishes that are less sensitive to humidity, like water-based polyurethane or lacquer with retarders. These can handle moisture better than oil-based finishes.

2.

Control Environment: If possible, use dehumidifiers or air conditioners to lower the humidity in your workspace. Aim for a relative humidity below 50%.

3.

Temperature: Keep the temperature consistent. A warmer environment can help speed up drying, but avoid direct heat sources which might cause the finish to dry too quickly on the surface, trapping moisture underneath.

4.

Ventilation: Ensure good airflow to help evaporate solvents and reduce moisture in the air. However, avoid direct drafts on the piece being finished.

5.

Thinning: Slightly thin your finish to improve flow-out and reduce the chance of blushing. However, don't over-thin as it can affect the finish's durability.

6.

Application: Apply in thin, even coats. Multiple thin coats dry faster than one thick coat, reducing the risk of moisture-related issues.

7.

Drying Time: Allow extra drying time between coats. Humidity can extend drying times significantly.

8.

Avoid Spraying in Early Morning or Late Evening: These times often have higher humidity levels.

By following these guidelines, you can mitigate some of the adverse effects of humidity when spraying finishes. Remember, patience is key in humid conditions.