Question

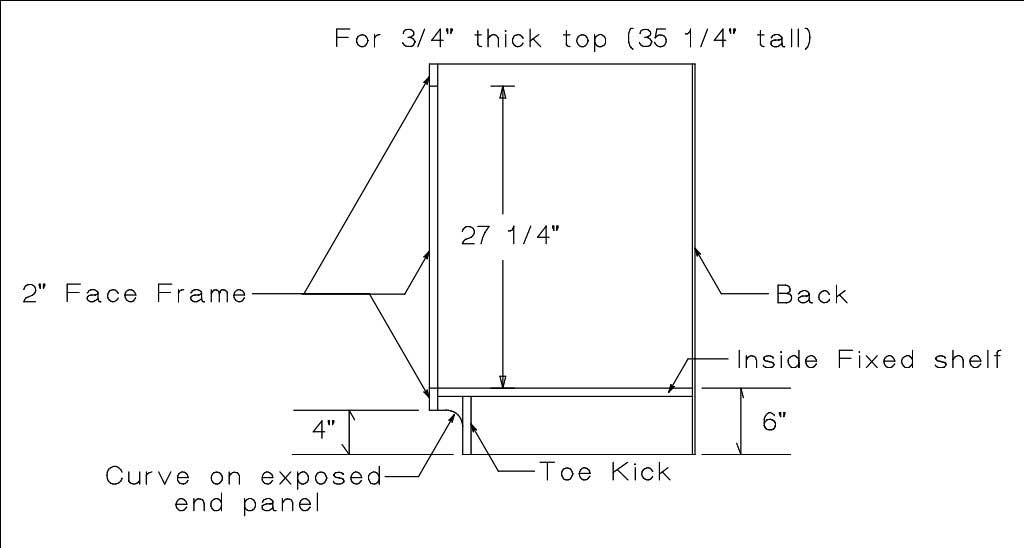

I've been making cabinets for more than 15 years now and I have never built a "standard" cabinet. All my cabinets have been furniture style with a lower toe kick than a usual standard box. Here is a drawing of what I think a standard should look like. I have a job that requires a standard box and need to know the correct dimensions for building one. The boxes will be 35 1/4" tall to accommodate the 3/4 " wooden tops. Here is the drawing, please tell me if anything needs to be modified to make it "standard".

Forum Responses

(Cabinetmaking Forum)

From contributor R:

Your side material will be 35.25 x 23.25. I cut the toe kick 4" tall x 2.25" deep ( with 3/4" face frame) Then if the bottom rail is 2" I raise the deck 1.25" so the bottom of the face frame is 4" off the floor. I also use a top rail of 2.5" so I don't have any trouble with a cutting board and the countertop.

Here in Tucson almost 90% of the tops are granite. They either use 3/4" or 1" granite. If they use the 3/4" they put down a sheet of 3/4" MDF backer first and if they are using 1" they put down a 1/2" MDF backer. There again adding up to 1 1/2" thick top. That’s why I make all my standard cabinets 34 1/2" high. As for the toe kicks, mine are 4" high and 3" deep including the face frame. My face frame ends up being 31" tall and with a 1/2' overlay on the doors; they end up being 28 1/2" tall.

Things like the distance from the bottom of the toekick to top of the bottom shelf will vary because there are no standard face frame member dimensions. I will list mine below just for comparison:

I usually make my bottom rails 1.375" (which is as narrow as I can make them with the dowels I use to create my face frames".)

My top rail is 1.75"

My exterior stiles are 2"

My interior stiles are 1.5"

My drawer rails are 1.5"

I use these dimensions for overlay doors and drawer fronts that cover .75" each side in width and .5" each edge in height.

For stringer/stretchers I use 3" wide by .75" thick plywood and I let them in to the finished ends, blind ends and interior partitions. This is a nice touch that the counter top guys like because the top of the face frame, finish end, blind end and partions are all flush with one another.

I use one stringer at the front right behind the face frame and one at the back. At the back stringer another stringer runs down from under its back edge 2.25" at 90 degrees creating a strong "L". This back rail is let into the partitions and blind ends and rabitted into the finished end. The cabinet back runs form the bottom of the bottom shelf to the top of the top stringer.