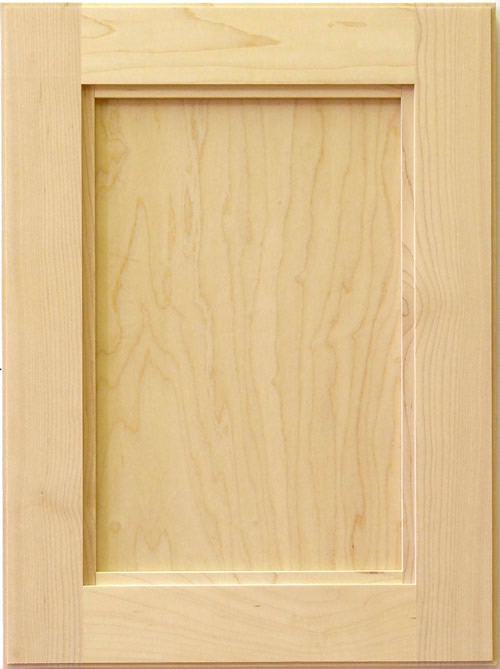

Does anyone have a cross sectional drawing of this door (see attached)? Its a step shaker door, trying to think of the easiest way to build these.

From contributor Br

Easy enough with a set of cope and stick cutters and a shaper. It's just that this profile is square instead of shaped.

From contributor p.

i get that part,, but how do you keep the profile square and make the opposite profile on the rail joint.

From contributor ra

When you draw it up to send to your tooling supplier, zoom in on-screen and put a very slight taper to it, if you think you need it. We have a square tongue for a shaker door. I don't think there is any taper to it. We also have a profile similar to this, just not as wide a flat. I can't remember if we a put a bit of taper to it or not. We don't have any problems assembling the doors.

From contributor p.

thanks ranliker, so you think i can get these cutters made then? or do you have cutters like this that you sell?

From contributor Ru

I have a few in different sizes if you want to browse our door rail profiles, just input the finish size your looking for, also check the smaller sizes for the drawer front details. Below is a link to a 3" wide detail.

I hope this helps you

Russ

From contributor ra

You can get them made. I don't sell them; I'm a cabinet shop. Looks like Russ can handle it if your regular tooling guy can't...or Russ can become your regular tooling supplier!

From contributor Ge

Looks like a standard shaker door with panel set back from center and a loose mold applied?

From contributor Da

Cope and stick is the terminology, and it refers to the positive sticking profile that surrounds the panel that is integral to the rails and stiles. Cope is the negative complement to the sticking that relieves the ends of the rails to fit over the sticking.

The purpose of cope and stick mortise and tenon joinery is to give a fast, easy to make joint with a clean look and increased glue surface area. The parts can be quickly and easily machined on a shaper and the tenons can also be made on a shaper with proper jigs.

While this can be made square edge with added 'stops', you end up making 13 pcs instead of 5, and then fussing it all together. 3 times the amount of work.

From contributor La

Cope & stick on your shapers. Outside tooling supplier if you aren't setup to make. If you do a lot of custom profiles learn to make knives for a lock edge set of collars, or even better get a couple of corrugated heads and some steel. All it takes is an 8" bench grinder, a soft, G or H white wheel & a diamond dressing point. A trip balance or postal scale. You will want to run them on a heavy shaper, 1 1/4" spindle. Not that you need the power, just that there will be some in-balance. For this profile you will need to make a square corner. Easiest done by offsetting knives in two different slots. Once you learn the process it is quite quick & easy.

From contributor Da

I believe Freeborn is making this profile as a standard choice in their catalog.