Straight Lining Rough Lumber

Other Versions

Spanish

Efficient methods for creating an edge. December 9, 2004

Question

I currently straight line rough lumber as follows. I apply a ~4" x 8' vinyl straight edge to the lumber using double stick tape. Then I run it through my table saw. Does anyone have a better method?

Forum Responses

From contributor D:

I take a straight edge longer than my working piece and run the two together side by side. Just measure the minimum distance from the outside of the straight edge to the smallest point on the work piece and set your saw to that width.

From contributor T:

I use my jointer now, but before that I straightened boards for my tabletops by clamping a 3 5/8" steel stud track to the tablesaw's fence with spring clamps, effectively lengthening the fence to 10'. Worked best when I made multiple passes, flipping the board and sneaking up to the final width. They went straight into the glue and clamps from there.

From contributor D:

If you want to make money, and time is money, you want to do it in one pass.

From contributor G:

I hot glue (just at the ends) a straight plywood offcut to the wood, and run the offcut against the fence with the wood on the table.

From contributor A:

I was in a guy's shop last year that had an interesting setup. Along one wall he had built a 30' laminated fence with a table about 12" wide - perfectly straight and flat. In the middle of the table he inset a small portable table saw (the blade parallel to the fence) that slid on tracks perpendicular to the fence. The table saw was slid on the tracks to set the distance he wanted from the fence. He could straight rip long boards for trim this way, and it didn't take up much room.

From contributor T:

Usually when I straight cut a crooked board it doesn't stay straight, but reacts to the cut. This is why I would make multiple passes. Watch out for pinching on the blade! A splitter would help for ripping crooked boards.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).Comment from contributor S:

I usually just tack the board to a piece of MDF shelving I buy from HD when on sale. Those are cheap, straight and long. You just leave your board hanging over the edge and run it through. The good thing about MDF is you aren't going to care if you mess it up.

Comment from contributor C:

I use a system similar to contributor D, but I attached the guide board to a 1/2" thick plywood sled and screwed a couple of holddown clamps to the guide. With the sled extending to the fence side 3" past the guide and 8" on the other side, I clamp the plank needing to be straightlined down to the sled and pass them all together through the saw. If I need to straighten a board narrower than 8", I throw in a couple of spacers so all of the bowed side is exposed. This way I can run a whole stack fairly efficiently and by staggering joins and biscuiting the sled end to end, I made one long enough to handle any lumber I buy and use it for all boards. I've used the same sled for years now with no problems.

Comment from contributor J:

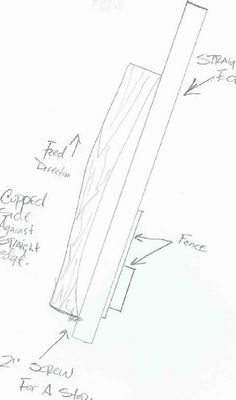

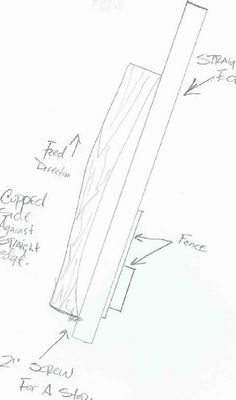

About straight-lining random length and width lumber... All you have to do is get a piece of plywood or MDF with a known straight edge. It should be at least 96" long. Rip it to at least 8" wide. Attach some means of anchoring it to your tablesaw fence. I ususally just screw a piece of wood 2" or so at 90 degrees to allow me to attach the jig to the fence. Decide what blade you are going to use for straight lining - ATB or whatever (not triple chip). Make another cut on the board with the outside of the sawblade even with the outside of the edge of the plywood. Start the cut about 3 feet in from the end that rests on your off feed table. Extend the cut through the end of the board. You have now effectively made your tablesaw into a long bed jointer, with the added benefit of not having to hold your boards on edge. Attach the jig and run your boards crown up and in. Depending on the lumber, it may take more than one pass, but I find it much faster in the long run than any other method. You could also stack blades if you wanted to take more off in one pass. Also, I have done this with a power feeder with good results. I have straight lined up to 12' material with no problems. This jig only takes seconds to put on the saw and remove.

Editor's Note: For sales and support of power feeders, portable edgebanders, JLT clamps, etc., Shop Gear (website) is a great option.