Question

We recently bought a US Concepts radius moulder, and tonight I ran a radius casing made from yellow pine. I used a stack laminated method like a butcher block and then the arch was cut from that. It made a mess. I really do not have the time to strip laminate and run it that way. Does anyone have any ideas or has anyone done this type of machining using my method? One of my competitors uses the same method and his seemed to come out fine. His arches were cherry and maple. Could I wet the wood and then machine it and sand it afterwards? My knives were sharp, by the way. Feeding the arch from left to right the cross grain leading into the head did fine and the cross grain machining away from the head tore out.

Forum Responses

(Solid Wood Machining Forum)

From contributor A:

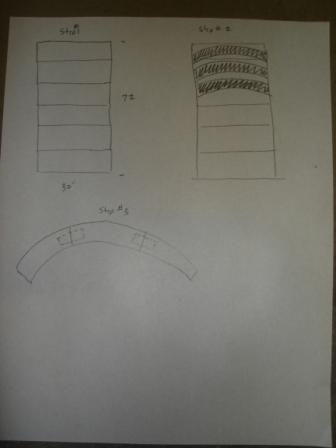

This takes awhile to learn and you will only get better by doing it over and over. If you understand the steps here it's easy to make the pieces separately and then nail them in place but if you have a large profile then it's best to glue the pieces together first and then profile them. Butt joint it with two biscuits or a loose tenon. Make an inside and outside track for the blank to follow and mould away. Taking light passes is better.