Question (WOODWEB Member) :

I've spent a few years focusing on cabinet building and before that years as a trim carpenter. Also, I grew up in my dad's cabinet shop (small) sanding, sanding and sanding some more. There are many differences from fabricating to trim carpentry, I know. Lately, I've moved into a new shop that has humidity issues (Virginia, 60% plus humidity and temps around 70 all day and night). I realize this question spans from cabinetmaking to finishing, please hang with me. My countertop's seams appear to be moving on me. I get either uneven seams, or recessed glue lines. I've gone to Trupan ultralite for a number of reasons, and face with poplar (flat sawn). I use a fair amount of titebond2 and clamp to squeeze air and glue out. I don't think I'm starving the joint even if the trupan soaks up so much glue. I then sand with 80, to ensure a flat surfaces (random orbit Festool), and then follow up with 120. I prime twice with MLC Magnaclaw, filling any gaps that might show up after first prime.

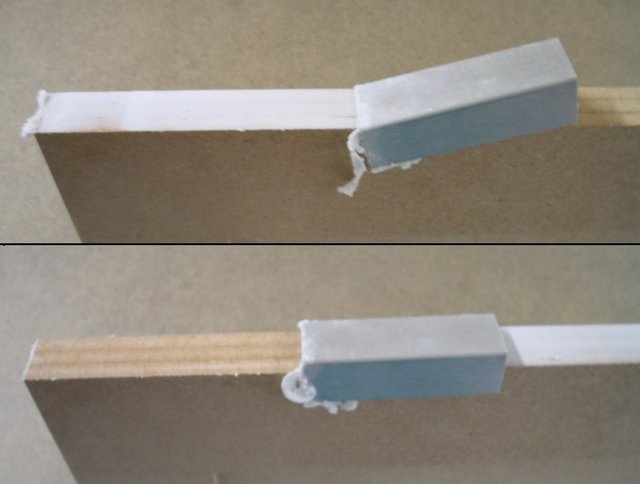

After second prime, I show areas where the poplar is standing proud of the trupan, or I have gaps on the glue line (recessed, but not void of any filler or glue). The glue line is at a lowest height, then the trupan and then the poplar typically stands the most proud. So I flatten that out with the orbital, ending in stripping the poplar of primer to get down to the lowest, flattest point. Also, it seems the poplar is quite porous. Sometimes the filler in the nail holes sinks in. I feel it would be better to sand up to 220(before prime), but that seems like too much labor. Any ideas on why my seams seem to move or my glue lines sink? The countertop sits for at least a day before finishing. I usually prime twice in one day, and topcoat twice in one day. Iím trying not to rush. I typically use reducers and retarders to deal with humidity and flashing too fast. Any thoughts on my fundamental question would be great.

Forum Responses

(Cabinetmaking Forum)

From the original questioner:

Note: In case itís not clear, the Trupan is lightweight MDF and the poplar is 3/4x1 1/2.

Contributor P - Bondo has worked great for me in the past. I recently tried Pro h20 from Wurth Woodgroup and the results have been less than satisfactory. Too soft, shrinks too much.

Contributor G - maple is great for paint grade, I agree. Every time I've had the helper sand edges flat on maple though, they never want to hang in there long enough to flatten it out! Itís quite hard. Maybe itís better to use a random orbital with an aggressive swirl rather than my Festool that has something close to 3/32 swirl for PG. This is why I've gone to 80 grit as a start to speed things up a bit. I knew a local manufacturer who would intentionally put saw kerfs in his seams just so he wouldn't have to sand flush on his shelves and such.

Contributor P - great find, wasn't aware Lamello made that - perfect for stain grade. Iím interested in the Profila. One thought occurred to me, what is keeping me from taking a standard laminate router and cutting a notch in the base like the Profila? Distorting the plate, sure - but it would make tape trimming so much easier. Right now I'm a small shop without an edgebander obviously. Something like that, or dedicating a routertable/shaper for trimming might be the ticket. I've used flush trim bits a lot for countertop edges and shelf edges, but one makes mistakes easily doing it that way.