Question

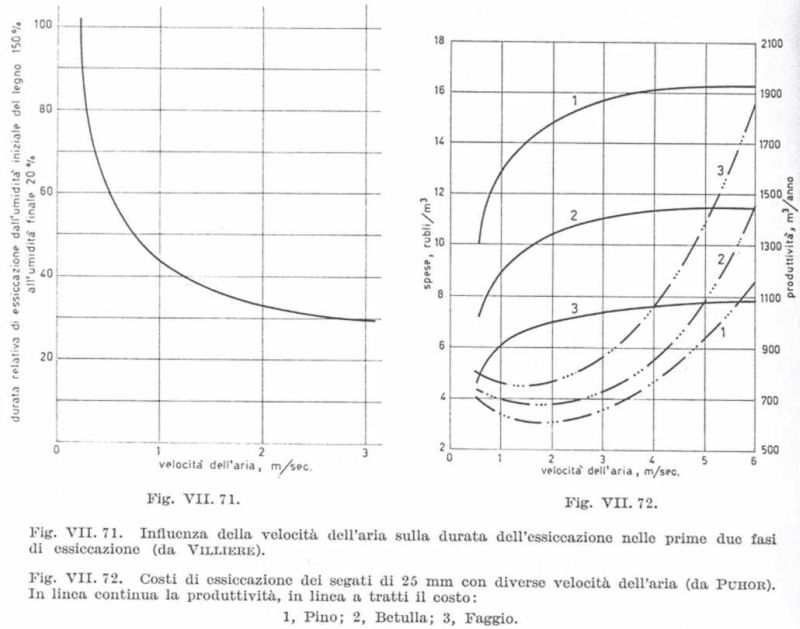

Does anyone know if there is any drying control system (with sensors) that can control air speed between timber while drying? I think this (the air speed in lumber stack) can be more important than the cfm of vents. The reason is that evaporation ratio depends on the air flow type and speed, more than its overall cfm value. With a low air speed in a lumber stack the flow is laminar, this means that near the wood surface air speed is near zero. Increasing air speed make the flow to become turbulent. The turbulence keeps high air speed on wood surface and generates hi-low pressure zones that mechanically extracts water. So I think that the best air speed is probably the one that guarantees turbulent flow. I read a book that told ideal drying air speed should be about 3-4 feet/second for a stack with about 1' spaced stack. I have no experiments data to confirm this. Since I'm quite new to the wood drying field I'd like your comments very much.

Forum Responses

(Commercial Kiln Drying Forum)

From contributor W:

Air flow is certainly important. The depth of the load, moisture content, accuracy of controls, sticker spacing are all factors. Water is not removed "mechanically" but by evaporation and that requires heat transfer. Turbulent flow allows better heat transfer than laminar flow. Whether you need it or not depends on several factors. Generally kiln designers plan air flow based on product. As controls have improved, air flow has increased, especially for green lumber for example.

You will also find that the surface roughness of lumber and the bumps between pieces result in no laminar flow in a dryer. It is always turbulent or in transition. If you are really interested in this subject, you can look at flow in a rectangular channel. Again, the boundary layer is not what is controlling the rate of drying (except when really wet). Your concept of mechanical removal is not correct. In short, drying rate (or evaporation) for lumber depends mainly on temperature and RH. In fact, kiln schedules give only those two values and not air flow. Finally, we do indeed have variable speed fans with a range of zero-ten feet per second. They are used at lower speeds to save energy, as low or fast, we get the same drying rate (at lower MC’s).

-Temperature of the air

-Temperature of the wood

-Humidity of the air

-Pressure of the air inside and outside of the wood

-Humidity of the wood and its distribution

-Structure of the wood

All these parameters (and probably others) should give the vapor pressure gradient. When the flow is turbulent we have moving low and high pressure zones inside the flow. This causes pressure variations on the wood surface. By theory it could effectively extract water from the wood caused by the different pressure inside and outside of the wood. Anyway since its value is probably very low this effect is very small.

Moving air particles in a circular turbulent way guarantees an air exchange on the wood surface. This exchange causes a better heat transfer and new fresh unsaturated air on the surface.

If the flow is laminar we have no new air on the surface so it can easily saturate and slow down very much with evaporation. I think this effect is very important.

In case of high moisture content, I think that with high air flow speeds (as Gene indicated) we have faster evaporation. The reason can be the mechanic hurting of air-water particles that transfers kinetic energy.

It's a little like after a rainy day. There is a big difference in the time roads dry out if there is wind or not. Anyway, Gene, if the air flow is always turbulent my considerations are not important and the boundary layer do not affect so much the drying rate. If it is laminar I think there is a visible slow down. So, is the ideal air flow speed the smallest that guarantees turbulent flow? I'll do some experiments in a little wind tunnel to check entity of pressure variations on surfaces at different speeds.

There is another thing, most important for quality to consider. When developing automatic drying schedules based on DG (drying gradient) DG equals wood moisture/EMC. It is important to know very well the RH (so EMC). If the flow is laminar your sensor measures something different (dryer) from real RH around wood. This is more evident if you are using electronic sensor or special cellulose strips (as our, very fast and precise) to measure RH. Sure, the main water resistance to evaporate is due to the wood internal structure. Anyway the outside RH value is fundamental. In fact we control drying speed by temperature and RH (or EMC) value.

As I mentioned in my last post roads dry out because water is superficial, and (as Gene too indicated) wind can speed up this process because the mechanical hurting of water-air particles.

A problem in my experiment is that I was thinking to measure turbulence in a little wind tunnel using a hot wire anemometer and a fast pressure sensor as a turbulence detector. The most sensitive pressure sensor I found has a sensibility of about 1" H2O (about 250Pa), and I think that is not enough.

Gene has made me think about roughness. After doing a little search I think that the small absolute roughness (about 2000 feet) of sawed wood will not affect low speed flows. Gene, can you give me some other info for this topic? I'd like to know more on this field.

We stated above that the evaporation rate of non-superficial water is function of vapor pressure gradient. I can't understand what you mean with my thinking of mass flow.

About the drying gradient I'm really surprised. In the plant where my friends work there are two types of electronic control systems, one German (very old, about 20 years) and one Italian (modern). In both types schedules for drying are based on DG equals wood moisture/EMC. With this approach the control system can keep constant the drying speed without any step of temperature/RH the wood doesn't like. In this way is also very easy to experiment different drying speeds.

For example, in the very successful technique of drying oak in the USA, when the MC is between 80% MC and 50% MC for 4/4 red oak, the RH is 87%. At 50% MC, the RH is lowered to 84%. So, DG starts at 80/17.5 and goes to 50/17.5 and then 50/16.2 to 40/16.2. So, this gives DG values between 4.6 to 2.9 and then 3.1 to 2.5. When the lumber is around 15% MC down to 7% MC, we would use 3.7 EMC, so the DG is 4.1 to 1.9. Incidentally, MC/EMC will not result in constant drying. The USA technique actually will achieve nearly constant drying in spite of the large DG variations. Wood does not reach the fiber saturation point because the surface reaches that level very early and the core very late. The piece of wood is never at the fiber saturation point. Only a small zone is at that level, or none is at the level when the wood is fairly dry. My favorite book is “Transport Phenomena” by Byrd, Stewart and Lightfoot.

The RH gradient between the lumber and the free stream air is so small it can be ignored, except when the wood is very wet. It becomes important with veneer. What is the RE when drying lumber? I think that you will find it to be about 8000. Incidentally, if laminar flow was a problem, please explain what the problem would be, as the drying time for most species is limited because of the internal stresses and not the transport of heat or moisture to or from the wood. It takes four weeks to dry oak because we cannot have the stresses buildup. The stress buildup is related to the rate of moisture movement (or the gradient) within the lumber. Please refer to a text on drying lumber to understand this more clearly. Again, the resistance to drying is the moisture movement within the wood and not the events at the surface of the wood. So, your idea that laminar and turbulent will affect drying until the core reaches FSP is not at all possible.

Many hardwood lumber dry kilns operate at well under 1 m/s air flow and dry wood nearly as fast as modern kilns with higher air flow when the wood MC is under 30-35% MC. As I have stated above, you can increase air flow when the wood is 25% MC and lower (average MC) and the drying rate will not change at all. Air flow, turbulence, laminar, etc. is not what is controlling the rate of drying. The drying rate of lumber is controlled by RH and temperature, and is limited by the quality that we require. Please read this previous sentence several times to make sure you clearly understand what is really going on.

With big kilns (100,000 BF or about 200 cubic meters) drying hardwoods, there is not a gradient of MC from side to side at the end of the cycle. That is why we reverse the fan direction every two hours. There may be final MC variations due to incoming MC variations or other wood factors. That is why we use equalization.

In softwood kilns, the limiting control variable is often the rate at which heat can be transferred to the lumber. This would be at temperatures over 110 C. Higher air flow assures more uniform drying. Sometimes air flow is 8 m/s. However, the electrical power cost for such high flow is huge and pays only when electricity is at a low price. DG would never be used for such drying anyway. The concepts for drying at these temperatures are totally different than what has been discussed so far.

Regarding the cellulose wafer, it is nothing more than a heavy piece of paper. It will, since the resistance to MC relationship of wood is the same for cellulose as for solid wood, have two electrical contact points and the resistance of this wafer or paper will be measured. (One kiln company actually uses small thin pieces of wood.) It is old technology. I first saw it with Hildebrand kilns 30 years ago or so. The first USA manufacturer I saw was Lignomat. Today, it is used by many companies. One advantage is that you do not need a water supply for a wet-bulb.

I was meaning to use the speed measure to keep it as low as possible, saving fans. More: an in-line system that measures air speed in stacks could help me to understand when I place lumber badly in the kiln (so it’s wasting air flow and money). If I place lumber badly I should see high fan speed and low air speed.

Contributor W - with the example of 5% you mean MC: 100%-95%, 15%-10%, orr 100%-95%, 15 %-14.25% (the percent of value)? Is there a paper on wood secure drying rates?

Air Flow: The laminar flow can be a problem because (as Contributor M indicated as well) you heat up wood slower (with the same air temp) and RH can be higher on wood surface (I know Gene doesn't trust much on it). It’s interesting about Contributor W’s note about measuring temperature (and RH) in and out of stacks to control speed and RH. It’s also interesting about Contributor M’s note about putting stacks in the kiln the right way

About Reynolds number amount in the kiln I don't know, but I'm quite sure at 0.1 feet/second it is below 2000. Anyway, till now, I didn't find a way to measure flow inline, inside stacks and in a precise way.

Cellulose strips: About cellulose strips what Gene said is correct. There is a constructor (more than one using the same device I think) that uses a threaded piece of paper combined with a particular measurement system so they reach EMC and RH measures near to an electronic sensor. On these strips there is a code but now I don't remember it. My friends have still a graph on paper about a nice comparison between special strips, classical cellulose, and electronic sensor.

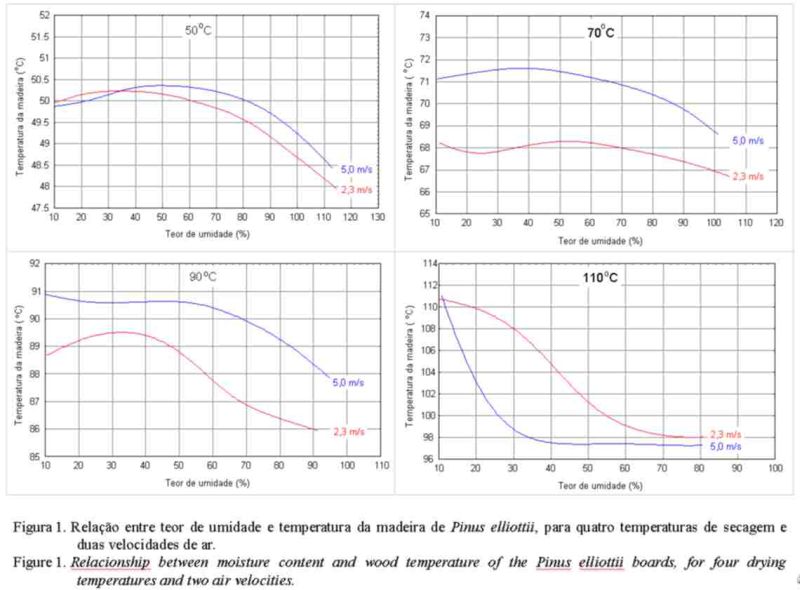

Note that the temperature difference at 10% MC cannot be supported by theory. At that low MC there is no drying occurring anymore, so the temperature will be at the DB nearly. Also, note that at 110 C the data shows a reversal of the temperature. It does indeed look like bogus data. Please note that data for hardwoods is given in “Drying Hardwood Lumber”. I included two different graphs in my book. Why not study these and see what is actually going on. If you want to study pine drying, then look at my book “Drying Southern Pine Lumber” which has some mathematical equations related to air velocity. Do you know the RE number has a distance term, so even if there is laminar at first, it quickly enters the transition zone? This is true especially at higher air speeds that pine is dried at.