by Stephen M. Bratkovich

Stephen Bratkovich is a Forest Products Specialist with the USDA Forest Service, Northeastern Area, State & Private Forestry, St. Paul, Minnesota.

Introduction

In the United States over 200 million cubic yards of urban tree and landscape residue are generated every year.(1) Of this amount, 15 percent is classified as “unchipped logs.” To put this figure in perspective, consider that if these logs were sawn into boards, they theoretically would produce 3.8 billion board feet of lumber,(2) or nearly 30 percent of the hardwood lumber produced annually in the United States.

The staggering number of tree removals in cities and towns across the country becomes necessary for a host of reasons. Storm blowdowns, natural mortality, severe insect and disease damage, construction activities, and many other circumstances can change an urban tree from an asset into a liability. Municipalities are faced not only with the volume of tree removals but with the associated financial costs as well. Rising labor and transportation costs, increased landfill or tipping fees, and lost opportunity costs (money that cannot be spent elsewhere in the community) create a financial burden for managers of municipal tree programs. Even if disposal costs were not an issue, landfill space is dwindling, and tree disposal in landfills has been either outlawed or reduced by regulations in many States.

Meanwhile, the American appetite for wood continues to grow. Although net growth on commercial U.S. forestlands exceeds harvest by about one-third, our nation is still a net importer of forest products. The utilization (recycling) of municipal trees can contribute to the conservation of forestland resources by generating wood products from trees that need to be removed anyway. Examples include sawlogs for high quality furniture, cabinets, and flooring; pulpwood for paper products; fuelwood for residential and commercial heating; wood chips for mulch on landscaping projects, and specialty items such as burls and branch crotches for unique woodworking projects. Innovators who are utilizing street, yard, and park trees for traditional wood products have realized that it makes economic sense as well.

To show how municipal tree removals can be utilized for traditional wood products, this publication highlights 16 successful projects from around the country. These case studies are organized by the different types of participants: State and regional partnerships, municipalities, tree service firms, entrepreneurs, and sawmills. Contact information is provided for each case study.

Other resources on the topic of municipal tree utilization are listed at the end of this publication. A subject index is provided.

(1) Whittier, Jack; Rue, Denise; Haase, Scott. 1995. Urban tree residues: results of the first national inventory. Journal of Arboriculture 21(2): 57-62.

(2) Conversion assumptions (cubic feet of residue to board feet of lumber) for the 15 percent of “unchipped logs” include a 70/30 percent volume ratio of solid wood to air and a lumber recovery factor of 6.7. Also, the study error was estimated to be plus or minus 16 percent. Consequently, the lumber that theoretically could be produced from the “unchipped logs” ranges from 3.2 to 4.4 billion board feet.

Partnerships

PROMOTING MUNICIPAL TREE UTILIZATION

New Jersey Forestry Services

Ed Lempicki has fielded his share of telephone calls over a 27-year public-service career with the New Jersey Forestry Services, a branch of the State’s Division of Parks and Forestry. In the late 1980s and early 1990s, however, he noticed an increase in the number of inquiries he received from municipal officials and tree service firms relating to municipal tree removal and disposal. In Lempicki’s opinion, not only were the number of calls increasing, but the significance of the calls warranted further investigation. In 1991 he sought and received funding from the USDA Forest Service, Northeastern Area State and Private Forestry, for a project titled “Municipal Forest Products Marketing Service.”

Statewide Survey Shows the Way

According to Lempicki, “The project enabled us to hire a full-time person who surveyed all 567 municipalities in the State to determine both their tree removal program and issues related to wood disposal.” A major finding from the survey was that tree removal and disposal was a costly burden to many communities. “Our next effort,” Lempicki recalls, “was to make one-on-one contact with municipalities with the greatest problems. We worked with them on numerous solutions including linking them with local sawmills and training them to market their better logs.”

Concept Spreads Across the Country

As word spread about the New Jersey project, Lempicki was asked to speak at conferences and workshops throughout the country. During the 1990s he gave about 30 presentations on the topic of marketing sawlogs from street tree removals. His enthusiasm for the subject spurred many of his State and Federal forestry colleagues to promote the municipal tree utilization message on a national basis.

Partnerships—The Key to Success

As a State forest products utilization and marketing specialist, Lempicki appreciated the value of partnerships when initiating the program in New Jersey. “The funding from the USDA Forest Service was critical to the effort,” he explains. “The Federal grant enabled New Jersey to take the idea to the ‘action’ level.”

Ed Cesa, utilization and marketing specialist with the USDA Forest Service in Morgantown, West Virginia, agrees with Lempicki on the value of partnerships. Cesa notes, “An established Federal-State partnership was in place, which helped make the New Jersey project a success.”

Due to the positive feedback on the project, Cesa approached Lempicki with the idea of developing a “How to” guide on the topic. “We took many of the principles we learned from the project and wrote ‘Recycling Municipal Trees: a Guide for Marketing Sawlogs from Street Tree Removals in Municipalities’ ” (Cesa and others 1994). The publication was a national success, and in conjunction with the one-on-one technical assistance to municipalities and the group workshops and seminars, earned the Federal-State team the 1995 Technology Transfer Award from the USDA Forest Service.

Another valuable partnership that Lempicki cultivated over the years is one with Rutgers University. He teaches a municipal tree utilization module at the annual Rutgers-sponsored Shortcourse on Urban and Community Forestry. This effort led to both Lempicki and Cesa being asked to contribute a chapter on municipal tree utilization in the 1999 publication, “Handbook of Urban and Community Forestry in the Northeast.” In addition, a publication detailing the economics and yield of urban sawlogs manufactured in New Jersey is being developed as a cooperative State and Federal effort.

Lempicki has also developed successful partnerships with the New Jersey Bureau of Recycling and the New Jersey Office of Sustainability. The latter provided a low interest loan for equipment to an entrepreneur selling third-party certified lumber manufactured from urban logs. The entrepreneur has found markets for the “rediscovered” certified wood among architects and other high-end outlets. Lempicki points to this example as just one of the success stories he has witnessed since the original project started in 1991.

Practicing What They Preach

In 1999 the New Jersey Forestry Services purchased a portable sawmill that is housed at the Division’s Forestry Education Center. In addition to being used for education purposes with school groups and tree service firms, the mill produces lumber for Division use, such as picnic tables, landscape ties, and paneling. Lempicki proudly notes, “Our mill saws only urban logs. We practice what we preach.”

For additional information:

Ed Lempicki

New Jersey Forestry Services

501 East State St.

Trenton, NJ 08625-0404

Phone 609-292-2520

E-mail elempicki@dep.state.nj.us

Ed Cesa

USDA Forest Service

Northeastern Area

State and Private Forestry

180 Canfield St.

Morgantown, WV 26505

Phone 304-285-1530

E-mail ecesa@fs.fed.us

Reference

Cesa, Edward T.; Lempicki, Edward A.; Knotts, J. Howard. 1994. Recycling municipal trees: a guide for marketing sawlogs from street tree removals in municipalities. NA-TP-02-94. Morgantown, WV: USDA Forest Service, Northeastern Area State and Private Forestry; 49p.

SEEING THE BIG PICTURE OF URBAN FOREST MANAGEMENT

Urban And Community Forestry Program

State Of California

As the State Urban and Community Forestry Coordinator for California since 1992, Eric Oldar has spoken to thousands of people about the benefits of trees and forests to municipalities. One of Oldar’s repeated messages is “Trees in a community should be seen as an asset, not just an aesthetic amenity.” He strives to get people to think of the urban forest as a “sustainable system.” One of his notions regarding “trees as assets” and “sustainability” focuses on the utilization of urban trees for traditional wood products. Over a period of 8 years, Oldar developed a network of partners across California to help him realize his dream.

Starting a Utilization Program

In 1996 Oldar convinced his superiors in the California Department of Forestry and Fire Protection (CDF) to purchase a portable sawmill and lumber dryer. The Wood-Mizer mill was loaned to the city of Lompoc, which used it to convert municipal trees into lumber products (see p. 23). The EBAC lumber dryer was mounted on a mobile trailer and loaned to Pacific Coast Lumber in San Luis Obispo, which was willing to partner with CDF in sawing urban logs and drying the lumber (see p. 77).

Expanding the Utilization Program

Following the success of the initial demonstrations, Oldar expanded the program by arranging for CDF to purchase four additional portable mills. CDF is partnering with the California Integrated Waste Management Board to construct a fleet of portable dehumidification dry kilns to be used in conjunction with the mills. According to Oldar, “It would be difficult to do this alone. Our demonstration project partners and our funding partners are very important to our success.”

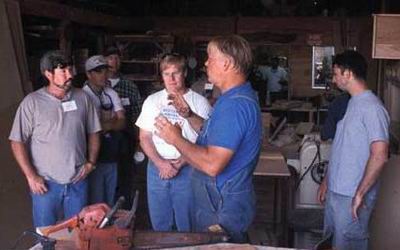

Numerous Partnerships Enhance the Program

In addition to demonstration projects, Oldar has led CDF in partnerships with the California Urban Forest Council (CUFC) in San Diego and with Pierce College in the San Fernando Valley of Los Angeles to jointly host workshops on value-added products from urban trees. He has been instrumental in organizing an Urban Forest Academy for municipal arborists where the “assets” philosophy of seeing the big picture of urban forests is taught. Knowing that education will play a key role in this new vision, CDF has entered yet another partnership with a school of fine woodworking-Palomar College in San Marcos, California. Students and faculty alike are exploring the new world of urban “working forests,” where wood that was once treated as just tree waste is being converted to high quality value-added products made of exotic urban hardwoods. Additional workshops focusing on woodworkers are being investigated through a collaborative project with the University of California’s Forest Products Laboratory in Richmond.

Oldar has also teamed with faculty at California Polytechnic State University (Cal Poly) to produce three publications on the topics of sustainability in urban forestry, urban tree volume equations for urban hardwoods, and urban wood utilization. The last publication is a 218-page document providing detailed information on the size, use, and potential of utilizing California’s urban forest resource. Future cooperative projects with Cal Poly include development of (1) an internet-based commodity exchange for exotic woods from the urban environment, (2) commodity standards for figure (grain pattern) in urban wood in lieu of standard hardwood grades, and (3) cubic foot wood volume tables to be used in conjunction with automated city tree inventories.

Seeing the Big Picture

Regardless of the audience or partner that he is networking with, Oldar continues to stress what he calls the “big picture” of urban forest management. “Planting trees and engaging people are important, but sometimes we don’t see the forest for the trees. We need to understand the urban wood waste management stream, which includes managing trees for age and species diversity and value-added wood products.”

For additional information:

Eric Oldar

Urban and Community Forestry Program

Department of Forestry and Fire Protection

2524 Mulberry St.

Riverside, CA 92501

Phone 909-782-4140, ext. 6125

E-mail eric_oldar@fire.ca.gov

CONNECTING TREE OWNERS WITH WOODWORKERS

Harvesting Urban Timber Program,

Cincinnati, Ohio

During the day, Sam Sherrill teaches economics, statistics, and computer graphics at the University of Cincinnati. During evenings and weekends, he is an amateur woodworker who has crafted handmade furniture for the past 20 years. Like most woodworkers, he typically had purchased lumber for his projects from retail outlets. An incident in the mid-1990s, however, changed Sherrill’s woodworking philosophy and led to a program that is spreading far beyond the boundaries of Cincinnati.

Fallen Tree Leads to New Program

In 1995, a University colleague of Sherrill’s spotted a fallen cherry tree along a street in Cincinnati. The colleague asked Sherrill if the downed tree had any value. Sherrill was not sure so he started to investigate the possibilities. Much to his surprise, he “discovered” portable sawmills and learned they could be used to mill urban trees into high quality lumber. Since woodworkers are always in need of good lumber at reasonable prices, Sherrill decided to pursue the notion of recovering lumber from municipal trees. He and his colleague implemented a pilot project in the City of Cincinnati. The effort was initially named the Trees to Furniture program; it is now known as Harvesting Urban Timber.

Partnerships Boost Program

Supporters stepped forward to help. “Popular Woodworking” magazine assisted in sponsorship of the program by promoting it in their national publication. Wood-Mizer Products, Inc. donated one of their portable sawmills to help serve as the workhorse for the pilot project. The Cincinnati Park Board assisted by cutting selected logs into proper lengths and loading them onto trucks. Local newspapers ran articles about Sherrill’s efforts to convert downed urban trees into lumber for woodworkers and into furniture. According to Sherrill, “The partnerships we formed really gave us a big boost in getting the program off the ground. We received support and exposure that tapped a latent sentiment in the public.”

“Popular Woodworking,” Wood-Mizer, and Sherrill and his colleague developed an educational brochure describing the Cincinnati program. The brochure is used by communities and groups to develop similar programs around the country. It also gives tips on topics such as tree selection and calculating board footage.

Sherrill says, “One of the objectives of the program is to hook up like-minded woodworkers across the country to keep downed trees out of the landfill and provide lumber for projects.” This objective is being met, in part, by the creation of similar projects in other cities, such as Hammond and Indianapolis, Indiana. On an informal basis, numerous woodworkers have been directly connected with tree owners who want to have their tree converted into a long-lasting product rather than end up in the landfill.

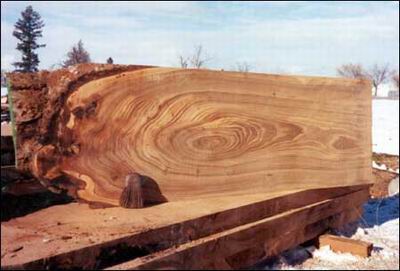

Family Tree Showcases Program

To illustrate the benefits of the Harvesting Urban Timber program, Sherrill highlights the story of a fallen bur oak tree that had been a silent participant in gatherings and events on a family farm since 1849. He says, “The blown-over tree, estimated to be 500 years old, had a trunk diameter of 10 feet with some of the limbs 3 to 4 feet across. It had sentimental value for the family. They commissioned me to make some furniture from it, starting with a 9-foot trestle table.” He completed the table with boards sawn from the tree’s limbs in time for the family to have its traditional Thanksgiving meal on it at the family farm. To date, Sherrill and his son have made 15 pieces of furniture from the tree, including three children’s rocking horses. Sherrill adds, “I am creating something of great personal value for this family from a tree that was a sapling about the time Columbus set sail for the New World.”

For additional information:

Sam Sherrill

5091 Beechwood Rd.

Milford, OH 45150

Phone 513-248-0509

E-mail samuel.sherrill@uc.edu

Since this 500-year old bur oak was blown over, its sentimental value has been preserved in the making of numerous furniture pieces, including a family dining table. Top, Gatch family photo, circa 1860. Bottom photo by Sam Sherrill

Reference

Sherrill, Sam. 1999. Bur oak. Popular Woodworking issue 110, 19(4): 78-80.

Municipalities

RAISING REVENUE FROM FALLEN TREES

Wausau, Wisconsin

Blaine Peterson wears two hats in Wausau, Wisconsin (population 37,000): one as the city forester plus a second as the Marathon County park forester. As city forester he is responsible for the management and maintenance of 26,000 street trees. His duties as county park forester include tree management in a dozen parks, predominantly in maintained areas such as campgrounds, and picnic and mowed areas. Regardless of which hat he wears, one objective remains the same-utilize as much wood as possible from tree removals from city forests and county parklands.

Tapping Into Local Markets

Wausau is located in the heart of the Wisconsin forest industry, within an hour’s drive of three paper mills. Peterson taps into these existing markets, selling municipal trees as pulpwood. In one instance, he contracted with an independent logger to deliver (back haul) logs to one of the mills. He paid the logger for his trucking costs ($10 per cord), and the mill paid the city of Wausau for the pulpwood ($40 per cord). The logger also sorted the loads, sending higher quality logs to a sawmill and maximizing the financial return.

Logs not utilized for pulpwood or sawlogs are often cut into firewood and sold at two county park campgrounds. Any remaining wood is chipped. With state law prohibiting wood residue in landfills, all of the chips are put to use, including these:

- Cover on fields of ginseng, an herb used for medicinal properties. Peterson often has the chips delivered directly to local growers, who spread them on their fields, sparing the city the cost of spreading or storage.

- Cover on wet and rocky areas on a municipal ski hill.

- Municipal landscaping projects.

- Protection for eroded banks and paths in parks.

- Cover material for dust control at a local open pit mine.

- Free chips for homeowners.

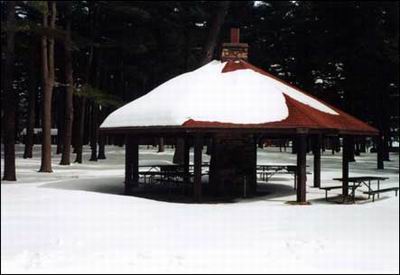

Peterson has traded lumber for labor. He negotiated with a local sawmill owner to turn large white pine logs from fallen trees into 12- by 12-inch timber beams for use in the city’s recreational shelters, and to keep a portion of the wood as payment.

Salvaged Trees Generate Revenue

For over a decade, personal relationships have been at the core of each of the markets Peterson has established for municipal trees. He was able to draw on these relationships in the wake of windstorms that blew through separate county parks in 1997 and 1998. He used his contacts to market the many downed trees as pulpwood and sawlogs, returning a total of $78,000 to the municipal coffers. Firewood permits, offered to the public at $25 each, generated additional revenue.

According to Peterson, “It makes environmental as well as economic sense to utilize as much wood as possible from our city and county park system. Plus, with all the nearby wood and paper mills, it’s also the logical thing to do.”

For additional information:

Blaine Peterson

9000 Pardee St.

Wausau, WI 54401

Phone 715-261-1558

E-mail bwpeterson@mail.co.marathon.wi.us

BORROWING A PORTABLE MILL YIELDS MULTIPLE BENEFITS

Lompoc, California

In early 1997, Parks and Urban Forestry Manager Cindy McCall was on the lookout for creative solutions. The Parks and Forestry Department of Lompoc, California (population 42,000) had two seemingly unrelated problems. First, the city could afford only inexpensive pine for the construction of park benches and picnic tables, and the soft wood was quickly damaged by skateboards and gouged with the initials of park patrons. Second, many of the town’s big trees were as much as 15 years past their normal life expectancy. The budget impact of removing these old trees was compounded by the concern for what to do with the wood. Like the rest of California’s municipalities, Lompoc was required to halve its landfill shipments by the year 2000 and was already mulching or chipping everything from grass clippings and fallen leaves to wood waste from pruned trees.

Searching for Solutions

McCall had the urban forestry crew fashion park benches with their chainsaws, and she donated logs to local artisans. But it was soon clear that these approaches would never use up the 100 or more large trees that were removed each year. Most of the wood ended up being chipped and used for mulch. Then she heard about the California Department of Forestry and Fire Protection’s (CDF) portable sawmill, which is available free of charge to qualified individuals or groups (see p. 9).

Portable Mill Is Key to Success

McCall received a 1-year loan of the mill, a Wood-Mizer LT30. It is small enough to pull behind a car or truck and powerful enough to saw logs 21 feet long and 36 inches in diameter. Before the year was up, her two-person crew had milled 130 trees, saving the city thousands of dollars in lumber costs and diverting valuable wood from the chipper. By milling the lumber, McCall was able to supply high quality wood for city projects.

Instead of using pine picnic tables, Lompoc city workers now use shammel ash, which McCall terms “indestructible.” Ash trees removed from sides of streets have also been used for flooring. The city refloored two heavily used storage rooms at a community center with 3-inch-thick hardwood. The total lumber milling cost was $120. Even 1-inch-thick hardwood flooring from the lumberyard would have cost $500 to $900, according to McCall. The extraordinary thickness of the flooring means that it will not need replacing for decades.

McCall is pleased with the low labor and maintenance costs to run the mill. She said, “My crew of two was trained on the mill in less than an hour. Each day they worked, it took only 10 minutes to set up the mill at the city’s nursery after towing from the corporate yard.” McCall estimates that blade sharpening, blade replacement, and routine engine maintenance “runs less than $20 per day.”

McCall has no doubts that the CDF loaner mill was cost-effective. Milling the wood has reduced the city’s tipping fees by nearly $40,000, and has allowed the Parks and Urban Forestry Department to use high-quality hardwoods for benches and picnic tables that require less maintenance.

Innovative Products

With access to ash trees, McCall’s Department offers potential philanthropists the opportunity to buy a hardwood bench, laser-engraved with the name of an honoree, for the park. A donor pays $1,000 for a memorial bench that costs the city about $200.

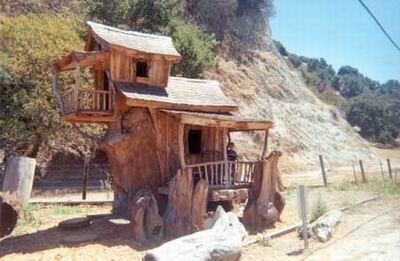

Another innovative project McCall has implemented is giving large tree trunks to a local chainsaw wood carver in exchange for wood sculptures for city parks and fund-raisers. Other products manufactured from Lompoc’s city trees include bleachers, indoor paneling, picnic shelters, and park signs.

Joining Forces With Others

More recently McCall has focused on collaboration and partnerships to enhance Lompoc’s wood utilization program. She is actively engaged in supplying urban wood to nearby Pacific Coast Lumber (see p. 77) and coordinating utilization efforts with West Coast Arborists (see p. 47). She spearheaded the formation of Santa Barbara County ReLeaf, which provides urban forestry assistance to the unincorporated areas of the county through a network of volunteers. One of the volunteers builds rustic western-style furniture from urban lodgepole pine logs. In turn, he donates 25 percent of the proceeds from his furniture sales back to the County ReLeaf project.

Trees Too Valuable to Waste

McCall sums up her municipal wood utilization philosophy by saying, “It seems crazy to be searching the tropical rain forests for underutilized species when we have an abundance of the same species being removed every day from our urban areas. Trees from urban forests should never be landfilled. They’re too valuable to be wasted.”

For additional information:

Cindy McCall

Parks and Urban Forestry Department

100 Civic Center Plaza

P.O. Box 8001

Lompoc, CA 93438-8001

Phone 805-737-0595

E-mail cmccall@ci.lompoc.ca.us

Reference

Bodzin, Steven. 1998. Waste not-want not: from urban trees to treasured timber.

California Trees 9(4): 4-5.

UTILIZING WOOD FOR ITS HIGHEST USE

Bismarck, North Dakota

In 1978 Paul Blumhardt was hired by Bismarck, North Dakota, to oversee a 2-year-old urban forestry program for the city. Bismarck (population 55,000) sits roughly in the middle of North Dakota, near the intersection of the Missouri River and Interstate 94. Agricultural crops dominate the landscape east of Bismarck, while ranches, rolling hills, and prairies dominate to the west. Tree cover is confined primarily to river and creek bottoms, farmstead shelterbelts, and the scattered and sparse population centers. At the time, finding enough dollars to fund the relatively new program was a concern. Blumhardt solved the funding problem through innovative revenue-generating projects, including ones involving municipal tree utilization.

Flooding Spurred Utilization Efforts

As city forester, Blumhardt attempts to use all trees for the highest and best use. In the mid-1990s a series of rainstorms put his convictions to the test. He says, “A few years ago we lost over 200 cottonwoods on a public golf course due to flooding. I made arrangements for the city to harvest the trees and found a local sawmiller who bought the logs.” The logs were converted into products such as corral boards, stakes, and lath. Smaller logs, less than 12 inches in diameter, were sold to a local firewood processor at $10 per ton. The following year a couple hundred more trees died on the golf course, and Blumhardt repeated the utilization process.

At the same time the dead cottonwood trees were harvested, a major landscaping project on nearby Interstate 94 required 2,000 cubic yards of wood chips. Blumhardt purchased a $24,000 Brush Bandit 280 to chip the tops and small limbs of the cottonwoods. The chips were sold for $12.50 per cubic yard to a nursery who had the contract for the interstate landscaping project. “We generated and sold enough chips to pay for the chipper in 1 year,” Blumhardt remarks.

City Landfill Is Focal Point

Blumhardt has arranged for the city landfill, operated by the Public Works Department, to be the focal point for many of the wood utilization efforts. Wood chips and firewood are stockpiled at the landfill and sold on a first-come first-served basis. Homeowners can purchase chips for landscaping purposes at 2 cents per pound; nurseries and others who purchase chips by the truckload can pay by weight or at the rate of $12.50 per cubic yard.

Firewood, at $10 per ton, is available at the landfill in log lengths of 12 to 16 feet. Individuals can cut the logs to length on-site, load the wood in their vehicle and drive across a scale to determine their payment. Also, Blumhardt has been instrumental in getting wood conversion equipment, such as tub grinders, to be demonstrated at the landfill after storms. Both residents and city officials are educated in wood utilization, and the demonstrations help convey a positive proactive approach. A Forestry Department web page also includes information on the city’s wood utilization program.

Two Decades of Accomplishments

Although trees and wood waste legally can be landfilled in Bismarck, Blumhardt avoids this option except for trees killed by Dutch elm disease. “Municipal trees are important on the prairie. When they no longer can shade our homes, divert the wind, or beautify our streets and parks, we need to find other uses for them.” Blumhardt’s efforts over two decades have shown that a municipal forest, in a relatively treeless region of the country, can produce an array of products for local consumption.

For additional information:

Paul Blumhardt

705 South 9th St.

P.O. Box 5503

Bismarck, ND 58506-5503

Phone 701-222-6561

Web address www.bismarck.org/forestry

BORROWING A WOOD YARD FOR STORAGE AND SALES

Cincinnati, Ohio

“All wood is good” is one motto adopted by Steve Sandfort, Supervisor of Urban Forestry in Cincinnati, Ohio. Sandfort, who manages 100,000 street trees on 1,000 miles of city streets, has achieved the goal of sending no street trees to the landfill. Since 1980, he and his staff of six employees have made every attempt to sell or recycle wood. One method of obtaining 100 percent utilization is the effective use of city-operated wood yards for selling firewood and chips.

Finding a Wood Yard

Each year the Urban Forestry Division “borrows” a different wood yard in an area close to the city’s scheduled tree maintenance and removal projects. The wood yard can be owned by a public agency or private company but must have these features:

- Fence with a locked gate to minimize theft and dumping

- Paved all-weather surface without parking bumpers, so vehicles will not get stuck in bad weather and the lot can easily be cleaned

- Large enough to store firewood on one side of the yard and chips on the other side, while allowing ample space for truck traffic during sales and cleanup

- Available for at least 1 year.

A publicly owned yard is usually easier to arrange since a private owner might ask the city to provide insurance. In either case, the Forestry Division must agree to clean the lot of all debris and repair all damages. The police, according to Sandfort, watch the lot and deal with dumpers or thieves.

Stocking Firewood and Chips

Cincinnati uses tree service firms (contractors) for all tree work. Since 1995, all contracts have been bid in one of two ways: either the tree service company keeps the removed wood and properly disposes of it, or cuts the wood to firewood length and puts it and the chips neatly in the city’s wood yard. After carefully evaluating the potential firewood and chip sales market, the Forestry Division chooses the bid most beneficial to the city. Since Ohio banned wood waste from landfills in 1993, most tree service companies operate their own wood and chip recycling operations, and many want city wood.

Marketing and Selling

Once the wood yard is adequately stocked with firewood and chips, the next step is to publicize the sale. Numerous marketing tools are used, such as a phone hot line, web page, mailings to past customers, media stories, door-to-door handouts in neighborhoods where tree work will be done, and signs on the wood yard fence.

Two staff members work each wood sale: one stays on-site at all times, and the other makes money drops, gets lunch, resolves emergencies, etc. The cut-to-length firewood is sold, load-your-own, by the cord (128 cubic feet) for $50; and the chips are sold, load-your-own, by the truckload for $10. Buyers pay cash for the amount of wood they take out of the yard. Often commercial tree planters purchase the mulch. A good public relations tool is to open and close the lot on time and to have fun. Sandfort says, “The wood sales are a wonderful change of pace for my staff. I want them to have a good time. It’s a morale builder.”

Cleaning Up After Storms

Cincinnati also uses the wood yard concept as a way of preparing for storm emergencies. The Forestry Division locates large wood yards, scattered across the city, primarily on public property. In this way they remain prepared to handle a huge amount of wood, brush, and chips following a bad storm.

For scattered minor or small emergency prunings, contracted tree crews are instructed to leave cut-to-length firewood stacked at the base of a nearby tree for anyone to take. Over the years the Forestry Division has developed a list of “wood users”—individuals who can be called to pick up wood that is not taken within 2 weeks.

Selective Cutting and Sales

As a professional forester Sandfort is keenly interested in the highest and best use for trees slated for removal. A competitive bidding process is used to sell sawlog or veneer quality street trees that must be removed. Many parks could be improved through selective timber harvesting, but often a “park mentality” opposes cutting trees, according to Sandfort. He sincerely commends privately owned Spring Grove Cemetery and Arboretum in Cincinnati, which is far better off because they have successfully conducted many professionally guided timber sales.

Using the Revenue

Sandfort is a firm believer in using revenue from the wood yard sales for tree planting in the neighborhood where the tree work was done. Another one of his mottos is “Harvest city trees for money, and use the dollars to plant more trees.” This strategy shows the urban residents right on the street where they live how rural forests should be managed. City codes mandate that the Forestry Division keep all revenues generated by their work, which “… gives us the financial incentive to hustle and be creative,” says Sandfort.

The Bottom Line

Sandfort claims the bottom line to implementing a successful wood utilization project is to “do what is right—just do it.” He confessed that in the bureaucracy of a large city it is always easier to get forgiveness than permission. Other city units, such as the law department, can help to implement ideas if the city forester approaches them properly.

For additional information:

Steve Sandfort

One Centennial Plaza

705 Central Ave., Suite 405

Cincinnati, OH 45202

Phone 513-352-3973

E-mail steve.sandfort@rcc.org

SUPPLYING FREE WOOD FOR ARTISANS

Able Tree Service

Missoula, Montana

Jim Cook, owner of Able Tree Service, has 30 years experience in the tree care business. His firm in Missoula, Montana (population 60,000) provides all of the services one would expect: pruning, cabling and bracing, transplanting, pest management, soil therapy, young tree culture, and tree removal. One service that sets Cook apart is his creation of a “wood artisan network” to which he supplies free wood. If a log is too big to chip and turn into mulch (greater than 12 inches in diameter) and has value-added potential beyond firewood, then Cook turns to this network to find new life for the wood.

Artisan Network

Soon after founding Able Tree Service in 1982 Cook realized that many of the trees he removed for homeowners contained valuable lumber that could be transformed into value-added products. Cook also realized that many local artisans were constantly seeking wood for their next project. Over a period of years he developed a database of approximately 40 artisans who use wood and live in Missoula and the surrounding valley. The database contains information such as the artisan’s address and phone number, the product made, and the wood species preferred. One of Cook’s objectives is to match the artisans with the appropriate wood species from his tree removal projects.

Currently, a wide range of products is made from Missoula trees by local artisans. For example, Cook has supplied basswood to a carver of carousel horses, blue-stained ponderosa pine to a log furniture builder, white birch to a lath crafter, and various hardwood species to a turner of wooden bowls. The University of Montana Extension Service has taken note of Cook’s expanding artisan network and plans to develop a computer web page to support his effort.

Cook also has stockpiled some trees and logs for future projects, although it is a guess what the future holds. Some of the hollow logs, for example, “might be used by local science teachers,” says Cook.

Free Wood Encourages Market Development

Cook believes that someday a market might develop that would enable him to sell many of his tree removals. “I want to encourage a market for municipal trees that are removed due to pest problems, storm damage, or old age. Right now, giving the wood away to artisans is the best thing I can do,” noted Cook.

For additional information:

Jim Cook

Able Tree Service

Box 8711

Missoula, MT 59807

Phone 406-549-9310

GIVING NEW LIFE TO OLD UTILITY POLES

Trees-N-More

Berryton, Kansas

In 1997 Kerry Burruss entered the tree trimming and removal business in eastern Kansas with pre-owned equipment and high expectations. One day he was asked by a homeowner to remove a healthy 28-inch diameter red oak tree. His reaction was one of disbelief because he saw no apparent reason to remove the tree. The homeowner had his mind set, however, so Burruss eventually did cut down the tree. After a difficult search he found a custom sawmiller who agreed to mill the butt (bottom) log of the tree. Burruss recovered some of the milled lumber, which was converted into various pieces of furniture. This incident caused Burruss to rethink his own business, eventually leading him to apply for a state grant and purchase a Timber King portable sawmill.

At the same time, only 10 miles away in Topeka, Kansas, Brad Loveless, Senior Manager of Biology and Conservation Programs for Western Resources, was facing his own wood utilization dilemma. Western Resources, a utility company serving over 600,000 customers, is continually removing old utility poles and replacing them with new ones. The traditional practice of disposing of the old 50- to 80-foot poles in landfills incurred significant transportation expense. Loveless and some of his coworkers were troubled by this seemingly wasteful practice. Loveless investigated the possibilities of milling the discarded utility poles into lumber, and his search eventually lead him to Kerry Burruss.

Business Arrangement Benefits Both Parties

In 1999 Burruss’s company, Trees-n-More, and Western Resources entered into a business arrangement that has been beneficial to both parties. Loveless arranged for the old utility poles to be delivered, on a back-haul, to Western Resources’ new-pole yard. Burruss set up his portable mill at the yard where he does custom sawing of the western red cedar, southern yellow pine, and Douglas-fir poles. Loveless says the arrangement is working well, “I give Kerry a list of dimensions to saw for and he takes it from there, sawing each piece to the specified width and thickness.” As of summer 2000, Western Resources had recycled 39,000 board feet of lumber and saved more than $77,000 in pole transportation and disposal costs.

Products From Old Poles

Kits and finished nest boxes for bluebirds, kestrels, wood ducks, and bats are a few of a dozen or so products produced from the old poles. During 1999 and 2000 over 2,600 nest box kits, made from the untreated portions of cedar poles, were given to and assembled by employees, local scout troops, schools, and 4-H clubs for habitat improvement projects. Other products constructed from lumber milled from the recycled poles include foot bridges, wildlife-viewing platforms and blinds, picnic tables, and shelters at schools, parks, refuges, and environmental education areas. Occasionally a project requires lumber thicker than 1 inch, such as an environmental education area shelter that used Douglas-fir timbers. “The shelter had 8- by 8-inch timbers that were 12 feet in length. The 3- by 12-inch stringers were 16 feet long,” Loveless boasts.

No problems have been encountered with residual preservative in the milled poles. “We avoid using the heavily treated butt ends of poles unless the product will be used in a ground application,” notes Loveless.

Sawing Complements Tree Service Work

From Burruss’s perspective the arrangement with Western Resources suits him just fine: “I’m able to do tree trimming and removal a couple days a week and sawing the other days. The pole sawing has given me a steady source of income.”

In addition to his utility pole sawing, Burruss continues to grow the other parts of his business. He has added a solar kiln to dry lumber milled from logs obtained from tree removal projects. The lumber is planed at a local cabinet shop, and species such as oak, ash, and walnut are sold to furniture builders and high school shop classes.

Burruss notes, “I like the tree service work I do; however, it’s the custom sawing for Western Resources and other folks that is my long-term goal.”

For additional information:

Kerry Burruss

Trees-n-More

2245 SE 61st St.

Berryton, KS 66409

Phone 785-862-1124

Brad Loveless

Western Resources

818 S. Kansas Ave.

P.O. Box 889

Topeka, KS 66601

Phone 785-575-8115

E-mail brad_loveless@wr.com

NETWORKING TO UTILIZE ALL WOOD RESIDUE

West Coast Arborists, Inc.,

Anaheim, California

“We used to see it as trash,” says Andy Trotter, “but now we see it as a product.” “It” is the residue, such as logs, from Trotter’s tree care business. Trotter is Vice-President of West Coast Arborists, which is headquartered in Anaheim, California. The company employs over 350 people and has annual tree care contracts with 90 municipalities in southern California.

Firewood used to be the primary outlet for the larger logs and branches from tree removal and trimming projects. “Our business doubled in 5 years, and the firewood dealers we supplied couldn’t keep up with the quantity we generated,” says Trotter. “Plus, we were looking for an environmentally friendly alternative to filling our landfills with wood residue.”

In 1999 the California Department of Forestry and Fire Protection (CDF) loaned a portable sawmill to West Coast Arborists to encourage and demonstrate municipal tree utilization (see p. 9). The unit was used to mill hardwood lumber from logs that traditionally would have been sent to a landfill, chipped, or converted to firewood. The high quality of the lumber produced and a growing regional interest in expanding the California hardwood industry convinced the management of West Coast Arborists to purchase their own mill. Trotter says, “The CDF loaner mill was instrumental in getting us started full-time on our own utilization program.”

Producing Lumber

A Wood-Mizer LT40 portable sawmill ($35,000) and a Nyle dehumidification dry kiln ($14,000) with an 8,000-board-foot capacity are the cornerstones of West Coast Arborists’ sawlog utilization program. Two employees are dedicated full-time to producing about 800 board feet of lumber per day. “The mill is capable of higher daily production,” says Trotter, “but log size, shape, and nails slow us down.” One solution to the nail problem, in addition to using a metal detector, is West Coast’s use of bimetal saw blades that can cut through about 30 nails before dulling.

Drying Lumber

After the better sawlogs are milled on the Wood-Mizer, the lumber is air dried for 2 to 10 months. After air drying, some species, such as ash and elm, need only 5 days in the dry kiln to reduce the moisture content to 6 to 8 percent. “This is all new to us, but we’re learning the drying characteristics of various woods,” Trotter noted.

Marketing

The lumber marketing portion of West Coast Arborists’ program has been assigned to Mike Easterling, owner of a new start-up firm called East-West Urban Forest Products. Easterling sells West Coast’s lumber to various outlets including woodworkers, school industrial arts programs, and hardwood retailers. Easterling says, “Black acacia, carob, and Carolina cherry are colorful woods and sell very well. Also, schools are willing to take a variety of species, which works well for us.” Easterling has two part-time sales people to help with the lumber marketing. He has acquired a “rediscovered wood products” lumber label that he hopes to use as a positive marketing tool.

Value-Added Products

Easterling also builds value-added products like park benches and picnic tables from West Coast’s lumber. The benches are sold to the communities from which the trees came, which completes the “recycling loop.”

Networking

Because over 300 tons of green residue are generated daily by West Coast Arborists, Trotter and Easterling are networking with others interested in municipal tree utilization. Logs are often delivered to mills in Southern California with similar utilization objectives, since West Coast cannot mill and sell all the potential lumber from their residue stream.

The wood utilization program grew to the point where West Coast Arborists hired a full-time recycling coordinator, Jeff Melin. Melin is responsible for the flow of hundreds of tons of green waste produced each day, including the use and marketing of sawlogs and other wood materials.

Trotter admits that the wood utilization project currently is a “catchy tune” with customers and his firm’s top management, and that lumber sales need to improve for the program to pay for itself. “Everyone has a good feeling about using recycled materials,” he says. “We need to spread the word about the potential of urban tree use.”

For additional information:

Jeff Melin

West Coast Arborists, Inc.

2200 E. Via Burton St.

Anaheim, CA 92806

Phone 714-991-1900

E-mail jmelin@wcainc.com

Entrepreneurs

PART-TIME RECYCLER PROVIDES BENEFITS TO CONSUMERS

2nd Chance Woods

Berryton, Kansas

A third generation woodworker with a reputation for quality craftmanship, Mark Duncan has an inborn passion for wood. As a landfill groundwater monitoring specialist for the Kansas Department of Health and Environment (KDHE), Duncan observed the large quantities of wood going to waste. Trees such as oak, walnut, hackberry, elm, maple, and cedar were routinely dumped at landfills and burned. Duncan jumped into action after reading an article in “Popular Woodworking” magazine about a municipal recycling program that converted city trees to high-quality lumber (see p. 13). In 1999 he started a business to give landfilled trees in Topeka, Kansas, a “2nd chance”.

Grant Jumpstarted Business

2nd Chance Woods received a financial jumpstart with $20,000 from a solid waste competitive grant program administered by KDHE. The grant helped Duncan purchase a Timber King portable sawmill and a 16-foot double-axle trailer. Adding a planer, table saw, and chop saw, Duncan launched his business and produced 20,000 board feet of lumber in the first year.

Landfill Provides Raw Material

To date Duncan has focused his lumber recovery efforts at one city-run Topeka landfill that is “dedicated” to trees and brush. Logs are dropped off at the landfill by the Topeka Parks and Recreation Department, as well as by private tree service firms. Duncan visits the landfill on Saturdays and loads his trailer, rated at 7,500 pounds, with discarded municipal logs. He uses a winch with a “rolling hitch” set-up to roll the logs onto the trailer. After securing the logs on the trailer he drives 15 miles to his rural home in Berryton, where he saws the logs into lumber. Duncan currently air dries his lumber but plans to build a solar kiln in the near future. Dried lumber is planed and edged.

Products and Markets

Lumber is usually advertised for sale to the public by word of mouth. Duncan has numerous repeat customers, which speaks well for the high quality and reasonable price of his product. Duncan also makes and sells indoor and outdoor furniture and construction lumber, and does custom woodworking projects. One of his trademark products is the EarthClamp, a hand screw clamp of exclusive design made entirely out of recycled materials.

Part-Time Is Just Fine

2nd Chance Woods is a one person part-time business, which suits Duncan just fine. Volunteers are welcome to help with sawing and are reimbursed for their time with lumber at the rate of 8 board feet per hour.

Duncan sees a bright future for 2nd Chance Woods. An abundant supply of free trees can be recovered from landfills, the market is good for his value-added wood products, and the public is eager to purchase his lumber at prices lower than in a typical lumber yard. He proudly acknowledges, “I’m recycling and providing a benefit to consumers at the same time.”

For additional information:

Mark Duncan

2nd Chance Woods

5535 SE 61st St.

Berryton, KS 66409

Phone 785-379-9326

E-mail mduncan@kdhe.state.ks.us

SELLING HANDCRAFTED PRODUCTS FROM SALVAGED LOGS

Urban Forest Woodworks

Logan, Utah

According to George Hessenthaler, in 1847 there was only one tree, a juniper, where Salt Lake City is now located. For over 150 years, however, the city has embarked on a vigorous shade tree planting program. He estimates there are now over 200 species and 5 million trees in Salt Lake City, and about 75 percent are hardwoods including walnut, ash, locust, sycamore, maple, catalpa, Russian olive, chestnut, and various fruit trees. After watching many of these trees be cut—due to old age, storm damage, or urban expansion—and dumped in the county landfill, Hessenthaler decided to take action. In 1988 he founded Urban Forest Woodworks to salvage urban trees and convert them into hardwood products.

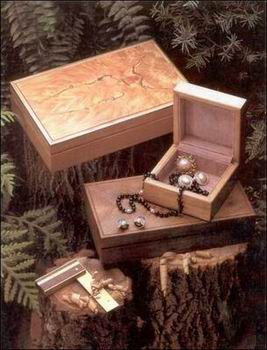

Product Line

Urban Forest Woodworks employs 3 to 12 employees, depending on the size of its custom orders. The company specializes in highly figured hardwoods in various sizes, species, and grain patterns. It produces a line of medium- and high-end jewelry and corporate boxes and sells them to the retail gift trade. Frequently, six different wood species are used in a jewelry box with classification of the box based on color—dark, medium, or light—rather than on species composition. Hessenthaler chooses not to use a single species of wood in a box in the event he might use up his supply of the species, forcing him into the community to “hunt” for the species. He does not want to become, in his words, “an urban forest tree predator.” The company also produces candle holders and trophy golf ball holders.

Hessenthaler believes the most important aspect of urban sawlog utilization is to “sell what you make.” There are perhaps over 300 jewelry box and case-making firms in the United States, as well as individual hobbyists, and European and Asian producers. Hessenthaler does not see the other case makers as competitors, but rather as potential customers for mini-bookmatch panels for case tops and for special case hardware that he has patented.

Gift store owners are receptive to the idea of selling products made from urban trees and are eager to display the brochures that describe the environmental friendliness of the products. Actual retail sales, however, have been based more on the quality of the product and less on the source of the wood. “People will not buy your product just because it is environmentally friendly,” he concedes.

Manufacturing Equipment

Hessenthaler estimates that during his first 5 years of operation he invested $250,000 in wages, equipment, logs, and incidentals, and essentially had a break-even operation. Because Urban Forest Woodworks mills its wood and manufactures retail products, the business has equipment for both phases of the work. Logs are sawn on a Wood-Mizer LT30 portable bandsaw equipped with a 18-horsepower electric motor. Hessenthaler’s self-built kiln can dry 4,000 board feet of green hardwood lumber in 25-35 days. Remanufacturing equipment includes a 36-inch-wide dual head abrasive planer and wide-belt sander, 24-inch Rockwell planer, and other standard wood shop equipment including several custom case-making sanders, shapers, routers, and saws.

Obtaining Logs

Annually, Hessenthaler mills about 50,000 board feet of logs to produce approximately 30,000 board feet of usable lumber. He can saw logs of various sizes but prefers all logs to have a minimum diameter of 12 inches and a minimum length of 3 feet. End-coating is used on all log ends to keep the logs from drying too quickly in the Utah climate. Hessenthaler has three rules he tries to follow when obtaining logs:

1. Not to cut down trees. (He lets a professional do it.)

2. Not to haul trees. (Log trucks are expensive to buy.)

3. Not to pay more than “firewood prices” for better logs.

In 12 years Hessenthaler estimates he has salvaged over 7,000 logs (250,000 board feet), diverting them from landfills into beautifully handcrafted products. He proudly proclaims, “By using discarded logs I’m doing my part to preserve the environment, particularly in rescuing the wood from our overcrowded landfills.” He goes on to say, “Anything made of wood can be made of urban forest wood."

For additional information:

George Hessenthaler

Urban Forest Woodworks

1065 West 600 North

Logan, UT 84321

Phone 435-752-7268

Reference

Plumb, Tim R.; Wolf, Marianne M.; Shelly, John. 1999. California urban woody green waste utilization. Technical Report 8. San Luis Obispo: California Polytechnic State University, Urban Forest Ecosystem Institute; (May) 218 p.

RECYCLING WOODY MATERIALS FROM A LANDFILL

Slater Industries Demolition Landfill

Lewisville, North Carolina

Joe Slater and his father, Frank, have operated an inert material landfill and recycling business for 10 years near Winston-Salem, North Carolina. Joe is a graduate of North Carolina State University’s furniture manufacturing and management program and is an accomplished machinery fabricator. Frank is semiretired and an accomplished cabinetmaker.

Eye for Wood Prompts Purchase of Sawmill

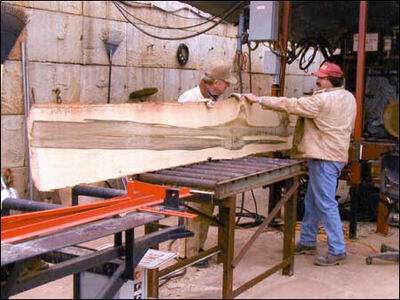

The Slater landfill and recycling operation primarily receives brush, stumps, logs and concrete. The source of the woody material typically is from tree service firms and land clearers. Because of their furniture backgrounds, the Slaters have an eye for wood and hate to see good logs go to waste or to the chipper. Because the chip market in their area is weak, they decided to purchase a portable sawmill to convert landfilled logs into usable lumber products. Joe’s father-in-law, Jim Millirons, was recruited to handle much of the sawing during normal operations.

The Slater’s mill is a Cook Accu-Trac and comes equipped as a portable mill; however, the Slaters did not need the portability once the mill was towed to their North Carolina site. They removed the wheels, trailer hitch, and lighting system, and constructed some additional jacks to keep the mill stable. The mill was mounted under a tarp on a recycled concrete floor to protect it from the elements. A permanent shelter will eventually be built.

Recycling at the Landfill

Of the 13 landfills in Forsyth County, only the Slaters operate a recycling business. Their philosophy is “what comes in, goes out.” Besides lumber products, such as packaging timber and survey stakes (sold to local utilities and land surveyors in 9- to 36-inch lengths, from pine, gum, and yellow-poplar), they produce mulch, topsoil, and crushed concrete products. The younger Slater is also sawing framing lumber and hardwood “grade” lumber for a house he is planning to build.

Sawmill Complements Recycling Business

In a typical week the sawmill runs 2 or 3 days, which nicely complements the regular down time associated with the landfill and recycling business. Daily maximum production is around 2,500 board feet in a wide range of pine and hardwood species. The mill can handle from 5- to 38-inch diameter logs up to 24 feet long. Large logs, up to 60 inches in diameter, are first quartered with an Alaskan chainsaw before loading on to the mill for sawing. Occasionally an individual will deliver a log for custom sawing. For example, one large urban black cherry tree was custom sawn for a homeowner, yielding 1,400 board feet of lumber.

To speed up the lumber processing, a three-blade Morgan edger was added after the first year of operating the mill. Having the edger has enabled the Slaters to use the sawmill exclusively to saw logs. Plans include the purchase of a small dry kiln to produce value-added products, as well as a tub grinder for processing lower quality material into mulch.

Products and Markets

Producing timber packaging products (3 by 4 inches, by 8 feet long) has suited the Slaters, because this market accepts lumber from the wide array of species and quality of logs brought to the landfill. If the Slaters started sawing for a specific hardwood grade market they would likely need to go out and look for logs. This would put them into the log buying business, which they want to avoid.

The Slater’s receive about 28 cents per board foot for their packaging lumber, which they sell primarily to a structural steel fabricator. They have sold air-dried red oak lumber for 60 cents per board foot. Occasionally, air-dried cherry, walnut, or quarter-sawn oak brings as much as $1 per board foot. Major customers for the higher quality lumber are local hobbyists and furniture makers. The Slaters also have been successful in marketing their higher quality mulch, which is produced using rented tub and horizontal grinders, to landscapers for $12 to $16 per cubic yard.

Operating Philosophy

The Slater’s have a simple and straightforward operating philosophy: recycle as much as possible by generating useful products to extend the life of the landfill. Their goal is to run a neat, clean, and sustainable business. Joe commented, “It’s not play, but I make my living from the landfill.”

For additional information:

Joe Slater

5334 Shallowford Rd.

Lewisville, NC 27023

Phone 336-721-5199

Reference

Denig, Joe. 1999. Portable sawmill review. Independent Sawmill and Woodlot Management 3(1): 5-7, 33-35.

READY BUYERS EASE RECOVERY FROM TRAGEDY

California Hardwood Producers, Inc

Auburn, California

Dave Parmenter, owner of California Hardwood Producers, Inc., in Auburn, California, has a list of lumber offerings that reads like a landscape gardener’s inventory: black acacia, Modesto ash, catalpa, red elm, blue and red eucalyptus, black locust, Pacific madrone, spalted maple, mulberry, black, tan and white oak, Italian stone pine, sycamore, claro, English walnut, chestnut, peach, apricot, and pear. These and other species reflect the trees he commonly mills from nearby Sacramento’s urban forest plus those he salvages from Northern California orchards.

California Hardwood has a contract with Sacramento to collect trees that otherwise would go to the landfill. Although Parmenter says he does not get each of the 4,000 to 6,000 trees brought down each year, he does find markets for all the trees he can mill. "We have never cut one speck of wood we have not found a buyer for,” he said.

Flooring Is Signature Product

Besides Sacramento, California Hardwood gets trees from State parks and fire control agencies, local utilities, and the State highway department. Milled lumber is sold to a couple of local manufacturers, in addition to 100 or so small cabinet shops. The company also recycles and sells timbers from old barns and warehouses. Culls and scraps from the milling operation are sold for firewood or mulch.

Flooring is the company’s top product, offering customers who want something different a wide selection of species. A rustic-looking knotty oak is the most popular. Parmenter also mills red elm flooring from trees killed by Dutch elm disease. Red eucalyptus flooring, which looks like Brazilian cherry, and Pacific madrone, sometimes called “Pacific cherry,” are also good sellers.

From Cooperative to For-Profit Operation

Business is good right now for Parmenter, but it has not been without major ups and downs. He entered the sawmilling business in 1992 with a Wood-Mizer portable band mill, sawing trees predominantly from small woodlot owners. In 1994 he started a hardwood sawmilling cooperative with four members from the Auburn area. Financial assistance was provided by a joint effort of the Sierra Economic Development District and the High Sierra Resource Conservation and Development Council. The cooperative started with two Wood-Mizers, two Mobile Dimension Circle Mills, plus a Madison 12-inch 226 molder which makes beautiful flooring. Before long, however, two of the cooperative members wanted out, so Parmenter and partner Alan Bales bought them out and became for-profit operators.

Tragedy Strikes Mill

In 1996 the California Hardwood Industry Initiative was established with funding from the U.S. Departments of Agriculture and Commerce. Among other things, the Initiative distributed funds through the Sierra Economic Development District through which Parmenter and his partner obtained $200,000 in revolving credit to grow the business. Parmenter says, “Soon we had $400,000 in equipment including a twin band resaw and four dehumidification dry kilns. We could cut 20,000 board feet per day.” In June 1997 they were sawing at a rate of 1 million board feet per year and had turned $150,000 in sales in a single month. At that time Parmenter was running the flooring moulder, his wife handled the retail and business office, and his son operated the sawmill. One month later, an electrical fire tragically burned the uninsured mill and warehouse to the ground, leaving him with a total loss and $700,000 in debt.

Rebuilding the Business

“I refused to declare bankruptcy,” Parmenter said. Instead, he sold his second house in southern California to pay off the revolving loan fund. Friends helped him obtain some equipment. He collected the insurance on a truck that had burned and bought more equipment. He found six discarded mobile homes and converted them into storage and retail space. Friends gave him some free logs to get started again. And then he went to work, eventually paying all of his bills. Parmenter says, “Quitting would have hurt others. I felt my purpose was to pay off the debt.”

Today, mill production is back to a half-million board feet a year despite having no permanent building and only makeshift kilns. The equipment mainstays of the business today are a new Wood-Mizer LT40 Super Hydraulic diesel-powered bandsaw with computerized setworks and a one-of-a-kind Baker twin-band resaw with automatic feed that can cut cants up to 12 by 12 inches in cross-section. He farms out his flooring milling to a local contractor he helped get started in the business.

Parmenter admits that he still has some distance to go to fully recover from the fire. Despite his growing production he still operates with limited equipment. He believes his optimal level of production would be about 5 million board feet a year. One of his goals is a large retail area, with a factory and warehouse. Another goal is to create a statewide marketing cooperative.

Parmenter notes that he could make almost as much money if he just cut all his logs into firewood; however, he sees so much beautiful California hardwood going into landfills that he does not want to take the easy way out. He says, “To me, this is a crusade.”

For additional information:

Dave Parmenter

California Hardwood Producers, Inc.

1980 Grass Valley Highway

Auburn, CA 95603

Phone 530-888-8191

E-mail dave@californiahardwood.com

Reference

Newton, Kathleen. 2000. Up from the ashes. Woodshop News 14(7): T29-T33.

PURCHASING MUNICIPAL LOGS: A WIN WIN SITUATION

Minnesota Valley Forest Products, Inc.

%