Veneering a Cone Shape

Interesting discussion of veneering methods for cone-shaped pieces. March 26, 2013

Question

I have a client (designer) that would like pricing on various sized cones. Cones are 1" tick staved MDF (by others) and turned smooth on the outside. How best to do this without mountains of waste and aggravation? I was thinking tapered strips or big sheets (4x4 or so) and doing half a section at a time?

Forum Responses

(Veneer Forum)

From contributor J:

Is this a full cone that comes to a point? I'd say tapered strips are the way to go, but it will be a pain for sure. I think I'd break out the hide glue.

From the original questioner:

No, no point. it's a table base. Small diameter on floor and large diameter supports top. Yes, pain for sure, but is there a way to make it less of a pain? Hide glue is a mystery to me. Hot, but not too hot. Work fast, but not too fast, etc.

From contributor J:

Okay, no point makes it a lot easier, or less difficult anyway. I've done these, only they were elliptical cones. I did them in the bag, with Unibond, with a very sturdy form inside. In hindsight, an inflatable bladder is probably the way to go. Thing is mine were not complete - there was an opening for a drawer and shelf. I'd leave one leaf out, most likely, and do that in a second pressing.

From the original questioner:

I really don't get it. Come again?

From contributor J:

Since my cone has an opening, it allowed my form to have a foot to sit on in the bag. That allowed me to wrap my taped veneer all the way around while in the bag because it was not sitting on part of itself. Does that make sense? So if I had to do it in two stages, leaving one out, or half at a time, I'd tape up the parts, and do the first pressing on top where you can see what you're doing. Your bag will have no platen in it so it can make it around this huge thing. You'll need extra hands. Use a caul of 1/8" bending ply. After that is done you'll have to scrape some glue off of the seam area for the last piece or second half. Then fit the pieces to the opening. I'd probably tape it to one side to make sure it won't get out of position when wet. Repeat the glue up procedure, rolling this side up. I hope you don't have too many of them.

Click here for higher quality, full size image

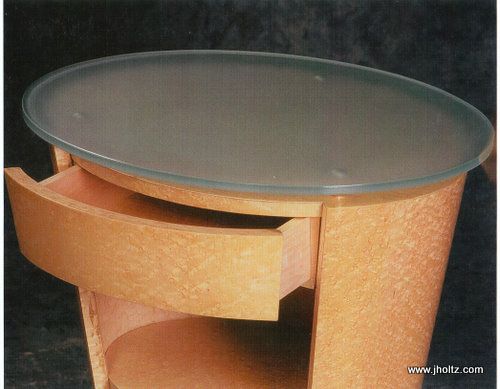

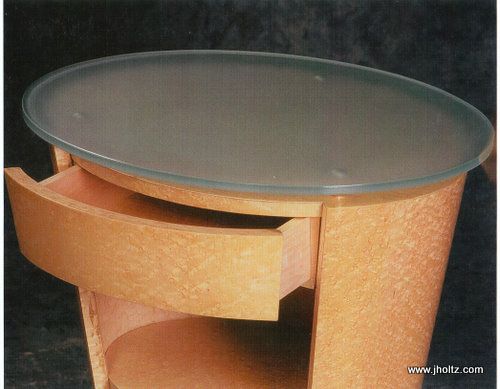

From contributor N:

Something like this? These are plywood core with plain sliced maple veneer, produced to customer specification (specs included the cleat you can see in the photo). The large one is 54" diameter at the top.

Click here for higher quality, full size image

From contributor F:

There is a very useful little computer program for tasks such as this at conelayout.com.

From contributor G:

Take lined paper, cut out a half circle and make a cone. See where the edges meet. The grain will almost be horizontal.

From the original questioner:

Maybe I should give the designer all your phone numbers. What about the glue/type of veneer (paper backed, oak wood type)? Do you vac bag it or are you using contact?

From contributor J:

Paperbacked veneer is only for those who lack the ability to lay it up themselves. As for adhesive, Unibond is the standard for things like this when you can really use a long open time. You could do it pretty easy with contact cement, but it's a poor choice. If you don't know why, a search on that subject in the Knowledge Base here will give you plenty of info.

From contributor E:

Veneering cones is a process fraught with the kind of risk us one-off guys love. Still prefer ice cream in mine.