Who cuts sink holes?

Other Versions

Spanish

Is this the responsibility of the cabinetmaker or installer? December 17, 2003

Question

This question is for those of you doing cabinets with solid tops, mostly 32mm melamine style. I am a countertop guy and getting real tired of having to cut the tops of the cabinets out for the sink. I cut the sink hole in the countertop and I feel the cabinet guys should cut the cabinets out for the sinks. Is this too much to ask? I back charge on some jobs $20 a hole to cut out the cabinets but I donít think the customer should have to pay this. I have been tempted to install over the cabinets and let the plumber deal with it, but then I would be doing to him what the cabinet guys are doing to me. Is this a standard thing for a cabinet shop to do or is it just in my area?

Forum Responses

From contributor A:

My sink base cabs are constructed specifically to accommodate the weight and dimension of a sink. This construction method leaves the top completely open for the sink. In the circumstance you are speaking of, I expect that if the cabinet top were cut out (as much as is typically required in a 36" sink base), the integrity of the cabinet would be at question, particularly along the front top edge of the cabinet. If I were strictly a countertop fabricator/installer, I would hesitate to go carving on someone's cabinet since I may cause unintentional damage and surely wouldn't want to invite that liability. If you can't encourage the cabinetmaker/installer to provide or prepare a suitable sink cabinet, you might insist that someone from their company sign a waiver in the event of any damage resulting from your installation process. That might get their attention and solve your problem completely.

From the original questioner:

It is nice to hear that you make allowances for the sink, and you are right about the integrity of the cabinet being effected - if it were not for our countertops, they would fall apart. When I approached one cabinet shop they said the customer would have to pay them more to cut out for the sink opening. Another shop said it was the plumberís responsibility. I am going to get tougher about having them do it right in the shop so we donít have to deal with it in the field.

From contributor A:

You might get other responses counter to what I am suggesting - don't know 'cause I have never had to deal with this particular problem. We also fabricate and install our own custom laminate tops so I'm sympathetic to your installation frustrations.

Couple of counterpoints:

If the cabinet shop stated they would have to charge the customer more, I would suggest they do just that - eliminates your problem. You also might talk to the local plumbers to see if it is common practice to make the sink and cabinet top cutout while placing the sink. I've always made the cutout on the sink counters I've installed, and I bill that fee into the cost of my tops, just as I do radius and clipped corners and special edges, just to name a few of the common upcharges. I set the sink to ensure it fits properly and the plumber is responsible for permanently setting the sink and (naturally) installing the plumbing.

I would expect the area and local practices might influence whether the cabinetmaker, counter installer, or plumber makes the sink cutout. It may be that you end up having to include a fee (as I do) for this service and go with the flow, so to speak. My counter jobs and cabinet jobs (as well) clearly detail the fees for each billable item that I list in my proposal. The most important point is that, if you are going to do the work, you must be compensated for the work Ė all of it!

From contributor B:

We do installs of cabs as well as tops, etc. (we fabricate it all, except for stone). The only disadvantage I would see from both perspectives is that the cabinet guy would have to know what sink you are installing and make the cutout, which may or may not end up matching your hole, unless you are going to use their hole as a guide. Not worth the headache, in my opinion. If they are going to do the work, they should also get paid to do it (I think you said $20), which I don't think should be a problem for the customer.

The customer gets plenty of freebies in the marketplace (i.e. free estimates, free sinks, free this, free that, etc.), I really don't think you should lose sleep over charging for labor you are performing, especially over $20.

P.S. Adding edge supports to the left and right of the sink cut-out, which rest on the cab, will negate possibly compromising the integrity of the cab. We do this as standard practice, and I've never had a service call regarding it (knock on wood).

From contributor C:

I don't think I would want a plumber cutting a hole in anything near my cabinets or ones that I've installed. Also, if a countertop guy can cut a hole in a top without hosing it up, I'm sure he can cut the top out of a cabinet. (How many times will he swear when he cuts into all the screws holding the cab top in place?) If the cabinet installer knows which sink is being used, he can cut it during installation. Otherwise the countertop guy is responsible and should not whine, but charge for it and keep lots of extra sharp blades on hand. Also, how does one compromise the integrity of the sink cabinet by installing a sink in it?

From the original questioner:

I have a thought - how about the cabinet guy making a sink base the right way without a solid top? If he makes the cabinet with a solid top and I cut most of it out, thereís not a lot holding the cabinet together and it tends to fall apart. It ticks me off when someone doesn't do their job right and expects the next guy to fix it for them.

From contributor D:

I agree with you all the way about hating to always fix someone else's mistakes because they didn't do their job. I would think that if you can't cut a sink cabinet to accommodate a sink without it falling apart, then it wasn't built very well or the sink and cabinet are not sized for each other. (By the way, I know some cabinetmakers and installers who refuse to cut in sinks. This baffles me, because I've prepped for sinks in every sink cabinet I've ever installed. I charge for it and do it correctly.)

Which sinks do you install mostly and how are cabinets falling apart after being cut? Just curious.

From the original questioner:

I wish more cabinetmakers had your standards. Most of the sink problems we have are for commercial jobs, and most of those sinks are 22x25 so they cut out close to the front and the way these cabinets are made when you cut out the top, no support is left in the front (because they are frameless). We screw the top down so it holds everything together. The real problem is that the cabinet makers are trying to save time and not make a separate style of cabinet for the sink bases. Some guys, instead of a solid top, run a 4Ē top rail and another one below the false front. These are run horizontally and need to be cut out for the larger sink that can't have a 4Ē set back. The top rail is not a problem, but the bottom rail is a bitch, and tends to break when you cut it out to allow for the sink, so usually I will just cut out the top one and let the cabinet guy get called back for the other one. But if I donít cut out the front rail or a solid top, someone will end up screwing up my top, trying to do it with the top installed, and I donít need the extra work right now.

From contributor C:

You described your headaches with sink cabinets concisely. When I need to cut for a kitchen sink, usually a 33x22 in a 24 inch deep frameless cabinet, obviously I am cutting out top and bottom rails, too. This is the standard way to make a sink base, while solid tops are, as you say, a shortcut that allows for standardization in construction. Fortunately I've convinced the designers that I work with to eliminate tilt downs, which are another headache altogether.

One way to beef up a standard cabinet is to screw in either one or two pieces of plywood - full height and width, right behind the false front (from above and below) before cutting the rails. This effectively creates a "beam" that carries a lot more weight.

Another method I've used is to span the cabinet with a piece of 3/4" steel square tubing at the very front, concealed by the top.

I think you'll have trouble getting cabinetmakers or installers to change the way they do things, that is if you even know who they are, and that you'll have to take the extra steps to make sure that your modifications keep the sink off the bottom of the cabinet.

Don't be afraid to hack in to a cabinet to get a sink to fit. If you leave it up to some plumber, you won't have any liability, but your client is likely to have a piece of crap installation, and you might be doing your top twice.

From contributor E:

Why even bother with rails? All you need is a front rail and a bottom rail as if they are faces to a cabinet. So the 3/4" edge is up. Then put corner blocks in, which are glued and stapled from the inside of the cabinet. Make sure you are far enough away to not blow the staple out the exterior of the cabinet. Or use solid wood corner blocks, counter-sink and then screw them on from the inside. Then there is no cutting at all with the sink cabinet.

If it's a 30" sink, I make the cabinet a 33", if it's a 33" sink, I make my cabinet a 36". This way, you make a happy plumber and since all sink configurations are different, it is applicable for all different situations.

Not that it's our responsibility to make the plumber happy, but that's one less headache someone will end up complaining to the customer about. I personally have had a few compliments from my clients who say how happy their plumber was that he had enough room to work and didn't have to squeeze into the cabinet to try and hook up the sink. You never know, that plumber may know people who are doing home remodeling and need some custom built-ins.

From contributor F:

Here in Chi, we mostly set the tops when we finish the cabinets. One of the reasons that cabinet makers put in the rails is for strength. Keeps the cabinet from twisting, thereby eliminating a lot of door or drawer adjustment. Custom shops will build sink bases whatever way they want, since they mostly install their own work. When a cabinet is made in another state and shipped, it has to have more strength at critical junctions. I have never had a problem ripping the front rail - takes about 1 minute to do. If the cabinets are set, the only rail you have to cut is the front one; the one in the back can be knocked out with a hammer. If you're cutting the rails with a saber saw, that is not the way to go - just pick up a skill saw and rip the front rail down to 1", screw or glue it to the top and replace the false front.

From contributor A:

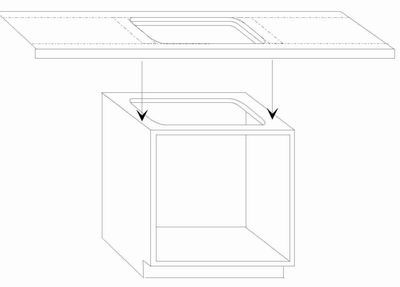

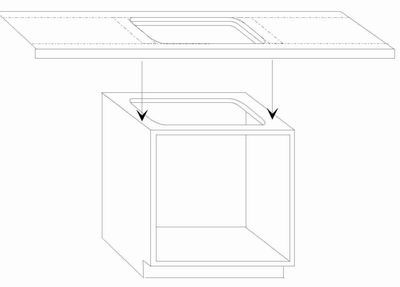

Here's a picture of my standard frameless base cabinet, drawer over pair of doors. The second image is my typical base sink cabinet. These happen to be vanity cabinets but the construction would be the same if they were for a kitchen instead of bathroom. They're older pictures and I've recently made one change to the construction of sink base cabinets. Instead of the rear rail lying horizontally, I also turn it vertically and install it down the rear of the cabinet similar to what I do with the front stretcher.

The vertical front rail is called a "sink base rail" and provides support for the cabinet sides, a solid mounting surface for the false drawer front, and by allowing 19mm (3/4") to protrude below the false front, it gives the look of a standard mid-rail and provides a place for the top of the doors to stop against.

As you can see, the sink base cabinet requires fewer parts and is quicker to build, so I don't know why it is that a cabinet shop would not want to build a base cabinet to specifically accommodate a sink and counter cutout.

From contributor G:

When the countertop is not fabricated by the cabinetmaker, it is really guesswork on where the cutout goes, especially when a customer rather than a designer is involved. I wish I had a nickel for every time the sink was upgraded to "something a little nicer." And the new asymmetrical sinks require different than normal placement (not to mention the undermount options). Cut it yourself, Mr. Countertop Installer, and charge for it. I doubt it's $20, either. Figure your costs and charge properly; it's a business thing. If you are being compensated properly you will not be complaining.

From contributor F:

Just put it into your agreement that if the sink base is not cut out and you have to spend extra time setting the sink top, then it will be charged back as extra work. The contractor is just going to hand the bill to the carpenter anyway, so it makes little difference of whom you give the bill too. Give it to the homeowner, they give it to the contractor, contractor gives it to the carpenter contractor, who throws it in the garbage because no one is going to court over $20.00. Another way is to walk in, look and see if it's cut out for the sink, if not leave and tell them to have the sink cut out and you will be back to set the top. You can draw a line in 30 seconds as to what has to be cut out.