Question

I am trying to decide the pros and cons of one real large unit located at one end that will run the entire shop or four centrally located units based on the four work cells. The relocation of a work cell or machines switched between cells is not an option due to workflow.

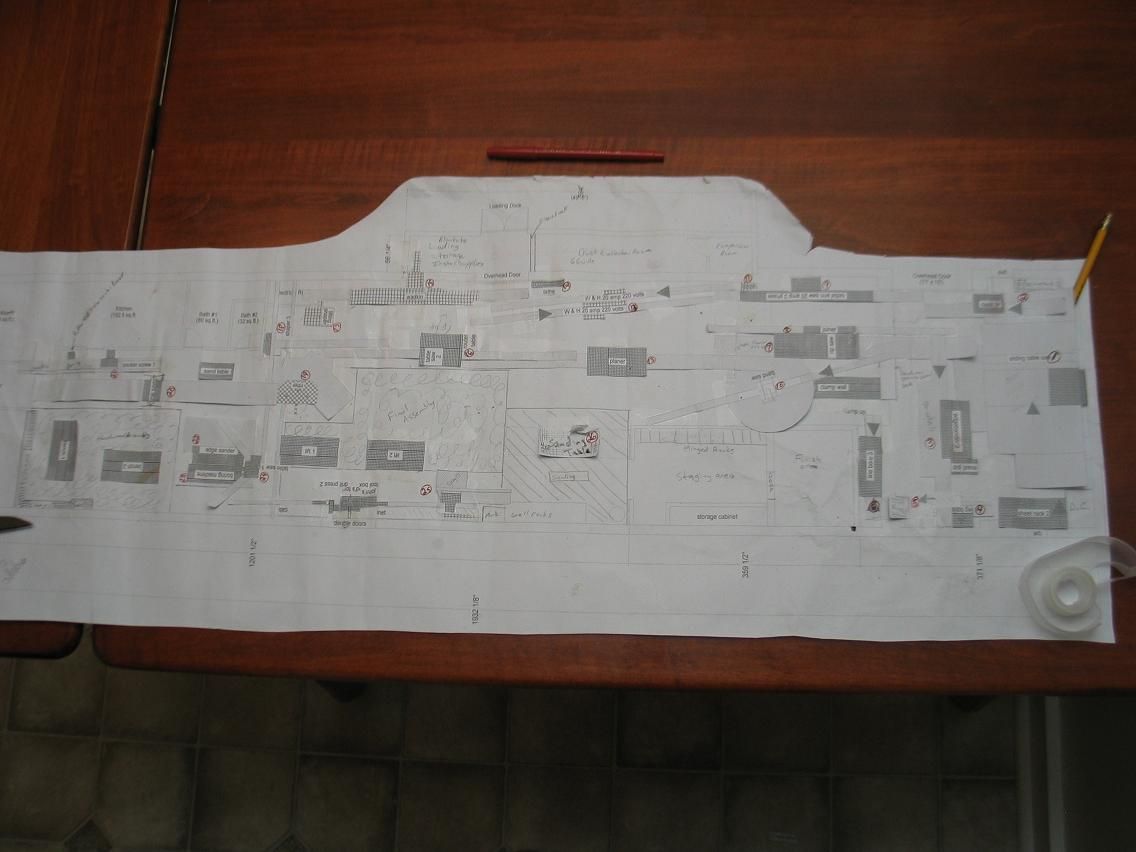

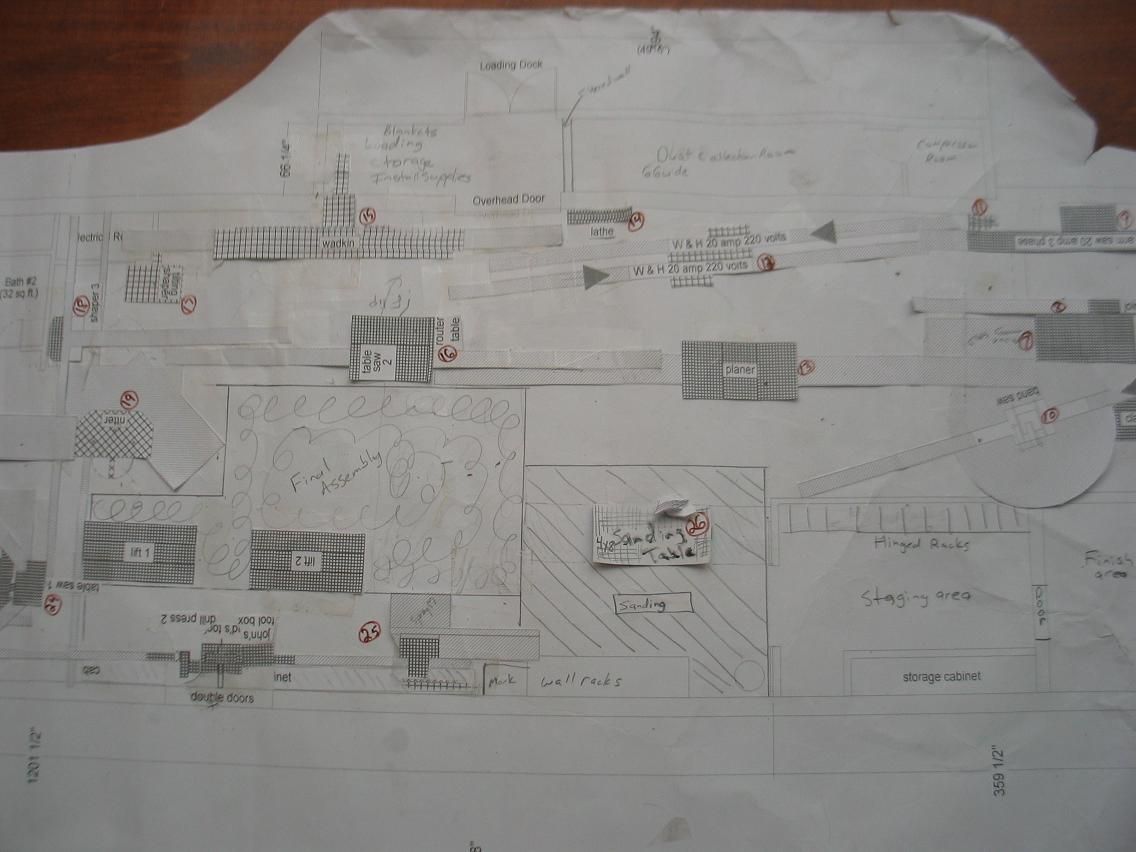

After much delay we are finally at the point of final shop layout. The layout will consist of basically four zones of machining stretched out over the length of the building. The building is 36x165 with an enclosed loading dock centered on one side that is 8x40. Besides the first cell, all machines will be less than 16' to one side of main trunk if one unit is used. All four cells are in line, so if one unit was used, one straight shot trunk line could run right down the center of the entire building.

No matter what system is chosen, everything must be indoors. If we go with one unit, it will be located in an area with 13' clear to ceiling. Worst case scenario, we could reconfigure truss layout above and run it higher, but obviously would prefer not to do this. I have quite a bit of floor space, so the footprint doesn't really matter, although obviously the less space taken, the better. If we go with four units, one will serve the sheet good processing area and be in the 13' height. The other 3 would be in an area with 9' clear.

Starting at the tall end, the first cell will have horizontal panel saw, edgebander, dado saw, dual head line bore, single head boring machine and pocket screw machine. This area is approximately 36x50.

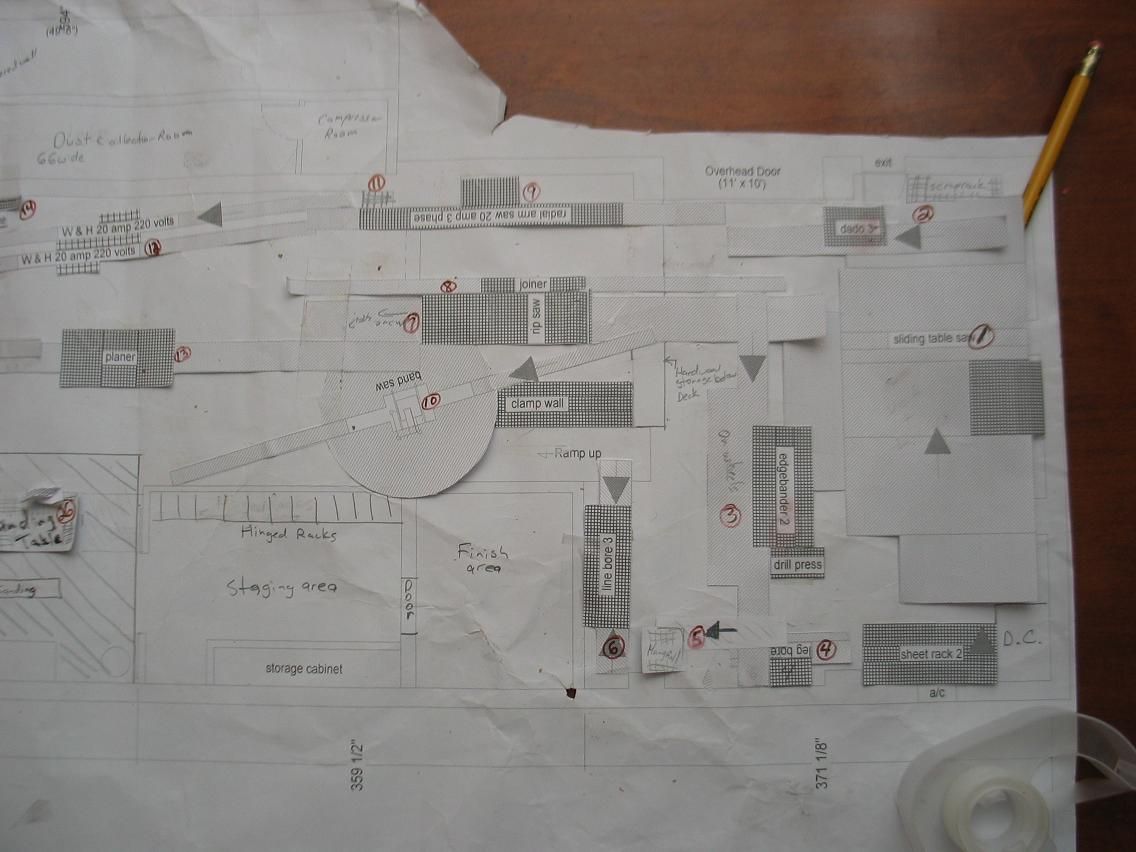

The next three cells are in the area with 9' ceilings. The second cell will start approximately 60' away from where single unit would be located. This area would include rip saw, s2s machine, jointer, radial arm saw, lathe and resaw bandsaw.

In between second and third cell, on the side is an enclosed loading dock where I currently have dust collection. The two units there or two new units could be placed there without taking up any floor space of machining area and serve both these cells.

The third cell would start approximately 95 feet away from single unit and would consist of one six head moulder, two Williams and Husseys, radial arm saw, chop saw and one Unisaw.

The fourth cell would start approximately 120 feet away from single unit and would consist of bandsaw, scrollsaw, pocket screw machine, six shapers, Timesaver, edge sander, single Unisaw, chop saw, euro hinge boring, and a single unit four spindle horizontal boring machine. There would be enough room leftover at this end to put a unit in to serve this cell by itself. If needed the band saw, scroll saw and a couple of shapers could be tied into third cell if we went with separate units.

Theoretically speaking, at any given time there could be a single person or team of people working on one machine in each cell at the same time.

The pros to having a single unit are central location closest to exit, larger capacity so less downtime to clean, and less electrical to run with one unit. The downside is very large unit, very expensive for all parts and accessories, plus large pipe overhead at beginning. Not really that critical, we could have up to 24" main running at ceiling down center where no machining is performed - it is just a through way for part carts. Another thing I am thinking is costs involved with on/off setup and dealing with gates opened on something far away from where you are working and having to walk over to close them. Do we use remotes, machine actuated blast gates, or manual blast gates with actuators? Worst case scenario, each cell could have the machine running with the highest CFM requirement (edgebander, s2s machine, six head moulder, Timesaver). To me it seems like I would need something pretty big to handle that scenario over a long stretch. The Timesaver would be about 140 feet from a single unit. There is one more thing with this setup that I believe will add more costs. Since all materials will be collected in same unit, I will no longer be able to give the solid wood waste to the locals for their barns. Our current setup has solid wood processing on two units in loading dock and another separate one for sheet goods. We throw away the sheet good waste and give away the high volume solids chipping.

The pros for four separate units are... Centrally located so lower power units could be used when one cell is going. (More likely that only one or two cells will be going than all four areas at once.) I believe the on/off situation will be an easier and less expensive setup, but am not sure. Doing it this way, the two solid wood processing areas could have the waste taken for free and we would only have to throw away the sheet good waste and fine particles from the cell with sanders. Another pro to this setup is I can easily find smaller used units and cheaper pipe and fittings since the vacuum will be lower on individual systems. The cons to this setup would be extra money for electrical setup, more legwork to take waste out of building, and I am not sure, but I doubt it would take less time to set this up compared to a single unit.

Thoughts, concerns, comments? Possibly even a completely different setup? Maybe two units, one on each end? Anything will be most helpful. This is really important. Whatever the decision, I will be contacting professionals to do final layout. It really comes down to what the most cost effective and functional approach will be based on all costs involved over a 5 year period. Does something that costs more up front with less labor involved over time make more sense? Or does less up front costs plus higher labor overtime make more sense, considering the ability to get rid of the majority of waste for free?

Forum Responses

(Dust Collection and Safety Equipment Forum)

From contributor L:

Think of it from another perspective: down time. What happens if your single unit breaks? The whole operation stops because of no DC. If you have four different units, you can continue operation in three cells and even use flex hose as a temporary solution to the broken cell.

It sounds like you are using a bag system instead of a hopper system, so emptying the bags on a smaller system will be easier because of the weight factor over a larger system. It may take more time to bring the bags to the waste area, but it will take less time/man power to do so than on a larger, heavier bag.

As for electrical consumption, you should be better off with the smaller units. If one cell is not in need of DC, then you are not drawing current for that cell (for DC), while all you need to have is one machine requiring DC for the larger system to need to be drawing current. Yes, the initial setup will cost more for individual units, but in the long run it should be offset by less total current draw and down time caused by shutting down your only DC for the whole building.

As you mentioned about giving the farmers your solid wood waste... This keeps your disposal fee down and also helps out the local farmer (good karma). Otherwise you will have to get rid of all your waste by means of disposal, which isn't getting any cheaper.

I have been downsizing for three years while creating a new master plan and relaxing, so I can't say exactly what volume will be. When I first moved here, I had 8 guys in the shop. My hope is that when we are flowing at capacity, there will be 8-10 people working throughout processing. This will also include finishing, assembly, and sometimes install. So best guesstimate would be three teams of two working at one of the cells at the same time, while the other 2-4 would be on final assembly or finish. I have my experienced mechanics now, so all new hires with the exception of one will be nothing but laborers. One of which will probably be doing nothing but cleaning and loading/unloading deliveries. Right now there are only three on the floor. For the past five years there have been 3-7 out there plus myself and wife doing front end stuff.

The moulder is in addition to what I have now. I know when we were running full bore on solids without a 6 head moulder, we were generating a dozen bags a day. But those days were few and far between. I would think when we finally reach full tilt over the next two years, the volume is going to be fairly serious for such a small place. I am not going to grow too fast again. I want to add one employee at a time and fully train them on our system before adding another. I can't have my main guys training a bunch at the same time or nothing will get done.

I didn't take into consideration the fact that the entire shop would be down while DC is being emptied. That would certainly be an issue to have five people with nothing to do while it is being cleaned. If we go with four units, then only one team would be down at a time, and while one was cleaning, the other could be staging materials or setting up another machine. Even more to think about.

I'm with the guys who say break the dust collection into smaller zones. My arguments for this fall along the lines of electrical consumption, noise, CFM/static pressure optimization. I had not thought of the very real cost of having all your machines stopped when the collectors need to be emptied.

We moved all of our dust collection to a mezzanine in the building. Every machine has a dedicated pickup and most of the collectors are 2 HP jets with custom felt bags on top of clear vinyl bags below.

You can make a small collector work like a big collector if you replace the cloth bags with felt (American Felt & Fabric).

We evacuate a 20 inch Martin jointer with a 2HP Jet collector. This dust collector has a 40ft run of six inch pipe, with most of the run at 45º or greater. The jointer dust is captured as well as it used to be with an up-down double cloth bag four feet away. This system is so quiet you sometimes have to check to see that the collector is turned on. I think the real creativity will come in figuring out how to get the dust from where it is collected to however it is conveyed out of your life. You have obviously thought a lot about this. I'm anxious to hear more about your shop planning.

What do you mean by this statement:

"The return air should be around 2500 FPM or less if all fans are on."

Do you engineer and sell dust collection systems? I'd like to know more about this system approach.

I do design and sell dust systems for a living. I do training seminars and consulting, 90% with the wood industry. The forum is a way for me share and learn some acquired knowledge about dust systems. After 30 years in the industry, I still pick up pointers.

2500 FPM is an air speed most workers in a plant will tolerate, low noise, low speed. There are various ways to accomplish this, but must break for now. I am interested to see the layout for this project.

Back of shop - Cell 1 Sheet good process

1 Horizontal slider

2 Dado saw

3 Edgebander

4 Single head borer

5 Shaper for hangrail/shelf wire chase

6 Dual head line borer

Back/ middle - Cell 2 Solid wood primary process

7 Rip saw

8 12" jointer

9 Radial arm saw

10 Resaw bandsaw

11 Radial arm dado/rabbet

12 24" Planer (would like to upgrade to 24"jointer/planer in near future)

13 Two Williams and husseys

14 36" lathe

Middle shop - Cell 3 Solid wood secondary process

Front - Cell 4 Hardwood sanding/prep

20 36" surface sander

21 Pocket screw

22 Edgesander

23 Euro hinge bore

24 Tablesaw for trim miters

Back:

Middle:

Front: