Question

I made the decision to buy a Weinig Quattromat and got a good enough price reduction to afford training from Weinig - which is readily available. Thanks for all the input. Next question is shop layout. I am interested in what others have come up with for layout relationships between straightline rip, molder, and widebelt and different ways to move materials - carts, conveyors, etc. - common pitfalls and cool ideas. We have done pretty well in our panel processing area, but the hardwood processing is still very rough and not lean.

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor D:

We put the Quattromat back to back with a Diehl SL 52 ripsaw. The two can share common catch tables/infeed/outfeed space. They feed in such a way as you can outfeed from one and infeed to the other. Both are located near the radial arm saw and lumber storage. We mostly cut length first - radial saw - then rip, then on to S4S. We also rip first, then S4S, so either way things are close together. If only a few boards are needed, the SL 52's massive table (like an aircraft carrier) will hold a goodly amount of material as it is ripped, then through the 4 head, and then stacked back onto the ripsaw or transport cart.

The wide belt is in the next "line" of machines (with a large joiner and a planer), so is close at hand. The molder is about 20' from the fan and fan inlet, so molder dust collection is tapped off a 13" main line and is very strong. The 4 head and the ripsaw have separate dust collection pipe as well as shutoffs. This has been in operation for only a few weeks, but is very similar to what I set up in 4 other shops similarly equipped, and worked very well.

Whether you are ripping and prepping a few boards or 25,000 l/f, you want to be able to get 16' fully loaded carts up to the infeed rip, outfeed rip, and molder without much effort. Another good thing is to be able to park the forklift at the rip infeed, with a load of 10/4 at a good height for manhandling to the ripsaw. Saves backs and related problems.

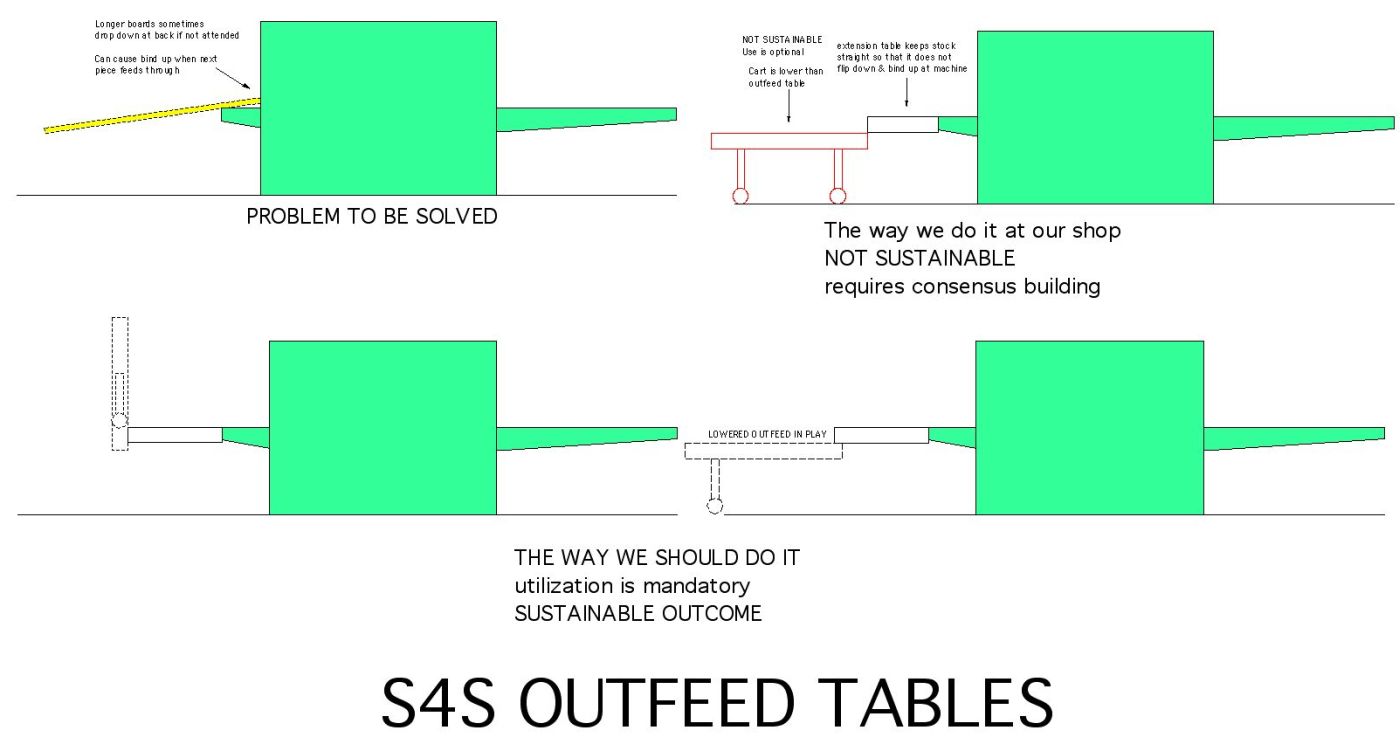

We've minimized this problem with an auxiliary outfeed table. The ideal table length would be slightly longer than half the length of your longest molding. This way gravity would always work to your advantage.

Another thing we need to improve on is how we catch the boards at the end (and how we sustain the use of this improvement). Having some kind of cart to catch sticks will reduce planer time by about 30%. This is a big reduction in noise, electricity, wear and tear, etc.

The trick is to sustain this improvement. It's hard to convince the guys to track down an outfeed cart if they only have a few sticks to run. The solution would be to make this outfeed cart mandatory. By hinging the system you have to activate it. What would be cool is to feed this material directly onto a chop saw station. A simple flip up stop on the Tigerstop would give you the option to chop sticks or collect them for chopping later.

Some good advice here on layout. One thing I can add is we keep our jointer steps away from the S4S machine. Even with a long jointer table on the T90, some cupped or twisted boards need an extra facing cut on the jointer.

For our setup we have a tight situation that does not allow for an outfeed table. What I do is keep 2 Aigner extension tables hanging on the end of the machine that can be installed quickly to make a 10’ table. Like you, a lot of times one person is just running a few parts. At least with this he can feed a few parts before making the hike to tail. I dream of a ceiling-suspended return conveyer that could be brought into play quickly.