Mike,

I agree that the 2 formulas seem to fight each other. Over the years, some Salice publications have presented the solution by solving for a negative number (the gap between the door and the side can be viewed as a “negative overlay”). I have always found this confusing.

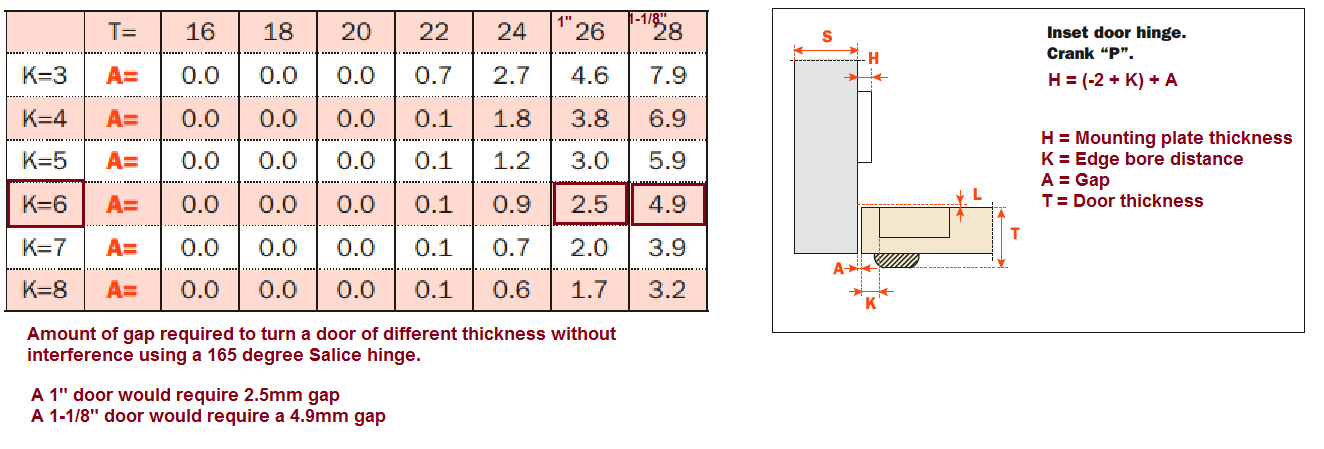

Note: These formulas hold true for only Salice hinges. Other brands have a constant (-2) that is different and therefore will result in a different solution.

I prefer Method 2 where you solve for the mounting plate height. It makes much more sense than having a negative number as the answer.

The results, however will be the same. if you use method 1.

A = Gap

K = Edge bore distance (TAB)

H = Mounting plate height

Method I: A = (-2 + K) - H

-2mm = (-2 + 6mm) - 6mm

-2mm = (4) – 6mm

-2mm = -2mm (gap or negative overlay)

Results: Gap = 2mm; Edge bore distance = 6mm; Mounting plate height = 6mm

Method II: H = (-2 + K) + A

Here, you arbitrarily set the gap that you would like to see then solve for the mounting plate height that will give that desired gap between the door edge and the cabinet side. The edge bore distance is determined by trial & error until the formula balances.

H = (-2 + 6mm) + 2mm

H = (4) + 2mm

H = 6mm (mounting plate height)

Results: Gap = 2mm; Edge bore distance = 6mm; Mounting plate height = 6mm

Now, as far as the amount of gap you will need to turn a door that is 1” (25.4mm) or 1-1/8” (28mm) thick using the 165 degree hinge, here is a chart showing the minimum gap required to turn a door of various thicknesses without interference.

Take note that as the edge bore distance (K) increases, the amount of gap required decreases. You can play around with the numbers to get exactly the outcome you would like.

This explanation is in context to your application being frameless or face frame with the side built flush to the edge of the frame.