Message Thread:

curved stair handail questions for professionals

10/9/14

Years ago I was the only stair builder I knew who manufactured curved stair handrail from solid wood. In order to do this I had to rediscover and learn archaic woodworking methods from more than a century ago. Today larger stair companies have at their disposal, 5 axis CNC machinery and sophisticated software. These "robots" can do almost anything but at what point will they be doing it all? And why aren’t they doing it all, already?

Here’s a few more questions…

1. Everybody knows the advantages of pre-molded, factory bending rail, but solid handrail is “simply better” (true or false?)

2. What would you say is the current percentage of the application of solid rail vs. laminated handrail within the stair building industry today?

3. What are some of the most common applications of solid rail?

4. Under what circumstances might you consider outsourcing for custom made, solid railings?

5. If you’ve already opted for solid railings, why?

6. Do you utilize both solid and bent handrail within your current operations?

7. In a reversal of history, do you think that bent rail will ever be eliminated from the trade or will there always be room for both?

8. Is the currently available CNC software and machinery now completely “foolproof, satisfactory and up to the task?”

9. Are you perhaps among the majority of stair builders today who’ve never really needed or used solid curved stair railings and probably never will?

10. Perhaps from a financial perspective, at what level must CNC railings be in order to compete with your bending rail preference?

Thanks for any responses.

View higher quality, full size image (1280 X 1024)

10/10/14 #2: curved stair handail questions for ...

First, I now only average one curved stair per year. We used to do more with more space, and more demand. I work in a residential market where the builder (sic) has carpenters bid and make everything, so quality is very low as well as expectations. Bending rail is the norm. In 40 years, I have never had anyone request solid curved or twisted - wreathed - rails. They do not know enough to even know it can be done, much less have an opinion.

I feel lucky to get the job and am hearing all sorts of talk about how to lower the cost (like those gawdawfull 5/8" iron pickets), so there is no way I can throw in a suggestion for wreathed rails, made by someone else. I simply don't outsource since no one cars about my work as much as I do.

1. It may be perceived as better by some, within the industry. Historically, the connections between sections are the weak point and what some people don't like when they fail - get loose. I prefer long bent laminated rails as that is 100% what I am familiar with.

2,. Locally, 98% bent laminated stock rails.

3......8 I use solid stock fittings if it is a stock pattern, otherwise I'll make the fittings out of solids. Laminations are only for flat curved or twisted rails. CNC programming has to be so expensive as to be only used now by large manufacturers doing hundreds/thousands of parts from one file. The promise of easy on-offs in minutes has not come about, and may never do so. If it does, then laminated rails may become the odd, unfamiliar method, replacing wreathing as an "outdated" method.

9. Yep. At this point, I'm an old dog.

10. I don't see it as sweeping the industry and making the changes it promised. The stairbuilders that are established with CNC will continue, but they have no motivation to make it widely available, and the expense is too much for the small shops to get involved. There will be no "curved stair building for the masses".

10/10/14 #3: curved stair handail questions for ...

Jim,

You raise some very good questions, I'm afraid you know all the answers already.

I think this market is poised to recover, and high end work will be the first to lead the way, the key might be to market to the architects because , they will have to spec a particular detail for the builders to follow otherwise it will be 6010 and 5015's all day long.

There is nothing easy about making curved rail, CNC or not, it's still the skill of the operator and designer to get it done right.

10/10/14 #4: curved stair handail questions for ...

dont get me started,lol. i have done millwork for 30 years. i have worked for 3 stairbuilders in the last 12. from traditional to the highest technology currently available. i can tell you a dozen ways to build stairs. there are risks and failures with each. BUT, given a choice i would always build in a traditional manner. in some cases ,there may be a reason for a short wreath near or with a fitting but i feel with a properly laid out stair ,they are few. with software a stair can be designed like a roller coaster, the handrail as well. its weird. with varying runs and radiusing points the stair may "work" but they just dont feel right. the last stair shop i worked for with a 5 axis had a 50% failure rate. parts in the dumpster not salvageable. i will stick with bending rail,fittings, and rail bolts.

10/12/14 #5: curved stair handail questions for ...

I guess I should first correct my spelling as in “handrail” and “professional” I hate looking stupid (which is much worse than actually being stupid).

Dave may be right at “98% bender rail” but why would stair companies be buying 5 axis machinery? These things don’t come cheap and real operational costs can be staggering. I know they’re out there though and will continue to make inroads into the marketplace. I’m actually surprised they’re not doing more right now.

Yes Steve, I know some of the answers and have opinions but I’d honestly like to hear from others. According to Dave for example, I’ve been chasing 2% of the market (and probably for the One Percent). Dave’s probably right.

Doug’s comments as in “50% CNC scrap” may be right-on too but I’m sure there are others who sing-songs of praise. Today’s CNC capabilities are truly astounding and should only become more so…

I’m also a bit dumbfounded by stair builders who only use bender rail. The limitations to me, seem so obvious. Perhaps it’s just from my point of view though, since all I see are stairs with non-bendable situations. I recently completed railings for a circle stair on a 6” radius with easements-to-straight above and below. This week I shipped continuous railings for a stair with 135 degree plan-view angles. These parts are for a stair remodeling job. The owners in this case, are paying a small fortune to correct a truly, terrible balustrade.

10/13/14 #6: curved stair handail questions for ...

There is a visible thrust towards CNC for three reasons:

1.It is part of the cultural mojo. We all know deep down inside that CNC is going to revolutionize everything we do, correct? All we have to do is mortgage the house and get on the bandwagon. To do otherwise is to drag down the entire industry and look like a Neanderthal.

2.CNC will allow less skilled people to perform the work of many skilled people that will (already?) no longer exist. More of the cultural mojo - that machines will be able to replicate what "Crusty" used to do. Skills will be transferred from the shop floor to the digital storage of a software library.

3.Wreathing, or even bending rail, is hard. Sometimes it is real hard. It requires lots of things; the ability to think clearly in 3 dimensions, and a thorough knowledge of woods, glues, tools and a clear perception of geometry. Occasionally there is a failure, but mostly it looks and performs well, but is still hard to do. CNC has arrived to remove the drudgery from the work and free up those (skilled, or unskilled?) people to do other things. Digital woodwork is easy - make a blank, secure it in the machine, hit the correct buttons, and ......a 50% failure rate.

I don't think any of my jobs over the years would have tolerated a 50% failure rate.

I think folks just don't want to get dirty, get splinters and a bad back - in short perform manual labor - anymore. They do not want to have to spend all that time acquiring knowledge and skills that are hard to learn, and still you can never be too sure you are right. They want to push around electrons on a screen, and get a sure thing, easily.

The smart shop would get their CNC running and then bring in Jim B or similar, and pay them exorbitantly to meld their knowledge with the requirements of the cad/CNC. The goal would be to train the next generation how to think like Jim does, but to act - to execute- with the machine. The CNC will then become an extension of the brain just as a compass or bandsaw is an extension of the hand.

I know of an artist that wanted to do digital work, but all he could do is draw. He met a bunch of coders that could only code. He learned to code, and can now draw and code what he draws, melding two disparate mediums that need each other. The result is digital art that is realistic and doable.

10/13/14 #7: curved stair handail questions for ...

ditto david. cnc designers and operators think they have all the answers. but when you hear the cutter screaming to fly out of the collet from across the shop any shaper operator knows something is wrong. and what you get is "oh the machine can handle it". meanwhile it gets knocked off pod and you just have to glue up another blank. i glued up 2 blanks for volutes. next day operator said i need 20mm bigger 2 sides. next day 20 mm bigger 2 sides. next day 20mm bigger 2 sides. 100 year old shaper technology. shift your pattern 20mm 2 sides and be done. or change your 00 point . or zero your cutter to right depth of cut. old school is way more obvious while cnc guys are like i think i can, i think i can, i think i can. _hen i asked 1 operator if he thought i could perate cnc he looked at me like i was an idiot . meanwhile he he still has a 50% failure rate.

10/13/14 #8: curved stair handail questions for ...

“Cultural Mojo”… I like that (even though spell-check doesn’t). Your right Dave, everything today has to be utterly foolproof (for fools) otherwise heads are going to roll. Those are the attitudes. "No apprenticeships and no old-timers hanging around."

I can appreciate the fact that everything changes so fast today that any traditional methods or training is considered obsolete or “old school”. Maybe this is true but working entirely without CNC, I haven’t scrapped any significant materials or parts in years. I know exactly the size of the material before I make a single cut and the rough stock is usually no more than 40 % greater than the finished, wreathed product. I don’t have to “guess-and-by-golly” and I don’t fret that parts won’t fit. As long as the plan-dimensions are correct, the parts are going to fit- period. Every job is different and every part is custom.

If this sounds like “pure braggadocio” it could be, but it’s not. It’s also not all to my credit but to those 19th century craftsmen who took the time to write instructional books and to those libraries who’ve kept dusty, old volumes on shelves. I suppose until someone writes a comprehensive, CNC instructional book, specifically for geometric handrail and stairs, there’s going to be more scrap.

Still, the future may find us all with our hands on keyboards (or in empty pockets). So where are all those CNC neophyte-fans, making their own fantastic claims?

10/14/14 #9: curved stair handail questions for ...

Jim, I wonder if years ago some old timer would have criticized you and your fancy machines, because you were not doing everything by hand with a collection of planes and scrapers. He would have laughed at how much you spend on tooling or how fast you were getting work done. Not to mention the CAD you used to complete your layout.

I think CNC machining is just another step in the evolution of woodworking and should be embraced and learned as progress.

10/14/14 #10: curved stair handail questions for ...

Those people that have not experienced or seen the products of a real craftsman (day in and day out) easily confuse their confidence for braggadocio. As a result, many adopt the bragging attitude as an attempt to convey confidence, though perhaps it is not yet deserved or earned. This is seen widely in this industry for some reason.

Perhaps because there is so little real craft that one feels the need to compensate by bragging about something like a cutting board. Then writing the book, then going on the tour of the 'schools' to talk about the trials and tribulations of making a cutting board. But my cynicism is showing.

CNC is part of a natural evolution in general woodworking and stairs in particular. However, it is by its nature a capital investment thing, a corporate thing, that is tasked with emulating what has always been an artistic thing, a craft. Think Enkeboll vs Grinling Gibbons in the world of carving.

As for the nature of craft, I can point to D C Nauman's current WoodWeb post (linked below) of a link to a book on craft. Harrington's words describe what so many have known and chased and achieved.

But craft is different from CNC. That fact does not elevate or denigrate either position, it is just a fact. In time there can be - and should be - craftsmen that use CNC to do things that are not done otherwise. But they will not replace the lone craftsman wreathing or bending, it will just make him more obscure.

Crazy? I Don't Think So.....

10/14/14 #11: curved stair handail questions for ...

Steve, I’m not criticizing CNC On the contrary, I want to hear from guys like yourself who can do and do do. But you make a good point…I’m no Geppetto, lovingly hand-carving Pinocchios and cuckoo clocks. This is business and every tool in the shed is fair play. If I could afford or justify CNC, I’d probably be spouting about that.

Dave, I really loved that article about craftsmen and your comments too. I do think I am afflicted with the same disease. When a persons’ work trumps common sense, you have to wonder.

I had the privilege of meeting Sam Maloof once and asked him how he felt about his notoriety. “All I wanted to do was make chairs” he replied. He didn’t seem to care about it at all. I joked and said “who’d of ever imagined your fancy butt-boards would’ve ever made it so big?” This elicited a smile and chuckle from the old master.

10/15/14 #12: curved stair handail questions for ...

Website: http://www.handrailing.com

Website: http://www.handrailing.com

Jim,

Great questions, and interesting responses. I wrote out a longer somewhat sour thing that I'd like think about more before put it in here. I'd like to have it posted in the next day or two.

I'm real glad you're doing this and thanks for all you've done to educate about solid rail. For what it's worth, I believe educating the architect and homeowner has been an important part of my ability to sell my work.

10/29/14 #14: curved stair handail questions for ...

Website: http://thestairshoppe.ca

Website: http://thestairshoppe.ca

I think the real point is woodwork is art and an art. Bending laminated rail will never be replaced by a machine. I have a friend who has been bankrupt twice trying to built a better mechanical stair stringer jig and now he is, for the last 5 year developing a system to mortise

spindles in the rail and stair stringer as well as profiling the railing. His efforts at rebuilding the wheel are commendable but not practical.

A laminated rail will always be stronger and when you find those 22 foot trees for the long curves then maybe a machine can bend rail on a slope.

10/29/14 #15: curved stair handail questions for ...

Curved vs solid will be an alternate, just as hand worked vs machine worked will be an option. There is a place for all of it, none of it will be mutually exclusive of the others, and the better craftsmen will have more than 2 or 3 ways to skin that cat.

Bending obviously gets to a point where it is better to work in solids, and fittings will always be solids, as I see it.

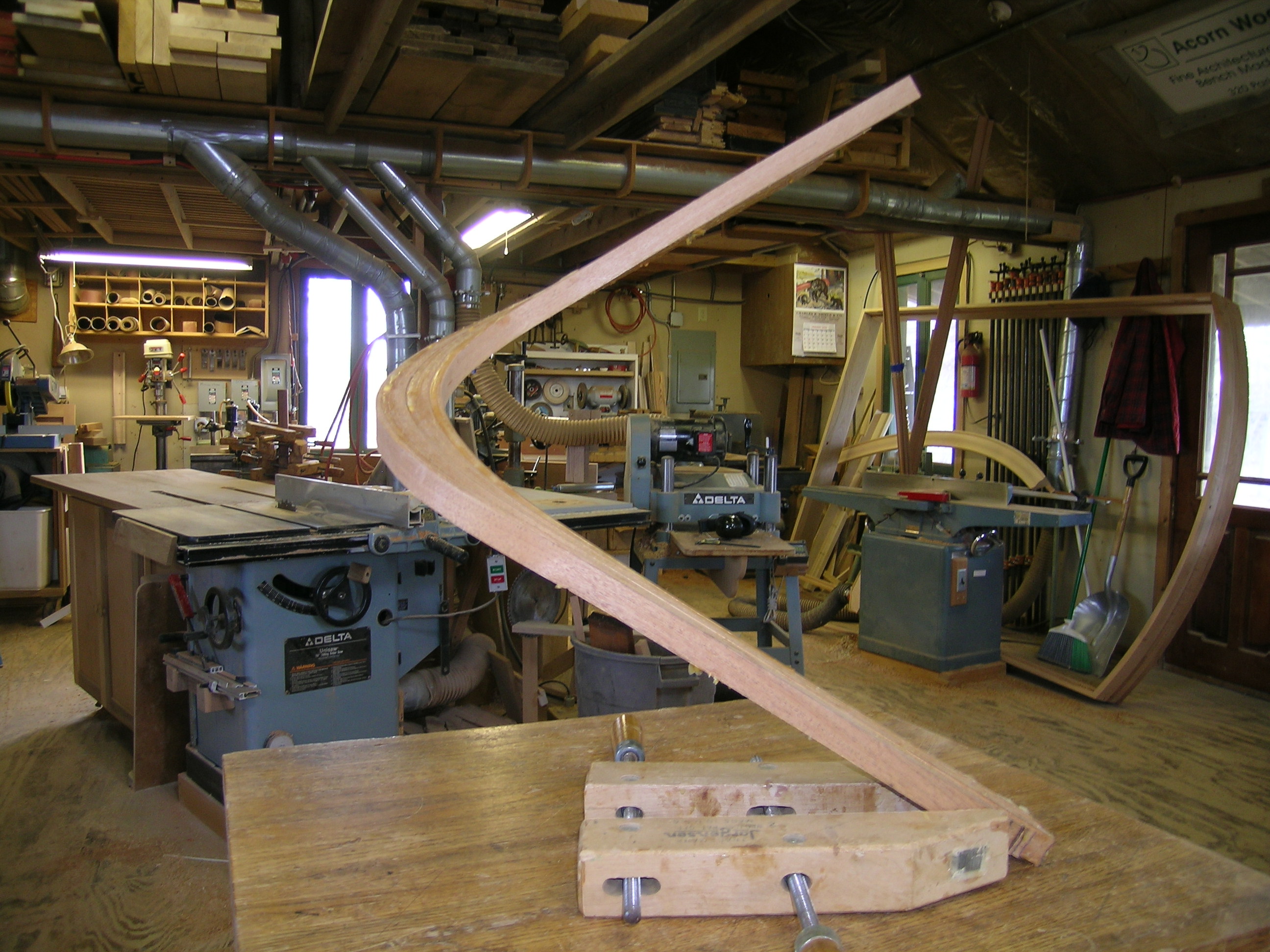

View higher quality, full size image (2592 X 1944)

View higher quality, full size image (2592 X 1944)

10/29/14 #16: curved stair handail questions for ...

Here's and example of a solid 180 transition also, before finish sanding. I'm happy to try it in solid over laminating.

View higher quality, full size image (720 X 1280)

10/29/14 #17: curved stair handail questions for ...

Website: http://www.handrailing.com

Website: http://www.handrailing.com

Jim,

It’s more than a few days, but here’s ‘tis:

I've got to assume that anyone doing curved stairs, and who has only used bending rail, has so fully adapted to those limits that the solid/tangent option doesn't compute.

Circular stairs are a premium feature in new construction, but I often wonder if anyone ever really notices what is often passed off as a premium architectural feature for the home and which may yet have abrupt transitions, and/or stacks of manufactured level turns and easements. Doing circular stairs without having the flexibility of adjusting pitch and plan radius as with solid/tangent rail is about the same as building with only the components you can take off a rack at Lowe's. On the other hand, for the stair fabricator/installer who is competing mostly on price, this alternative universe is at least a hard sell and a distraction. If their business is working and the customer is happy with the product, why mess around?

The staircase and especially a circular one is often the most visually interesting element in a house. Jim, what you and I do lifts a standard furniture sort of item (the stair and stair rail) in a home out of the prosaic and standardized. But in most cases, the builder or stair installer is only going to go this route if the owner or architect has a little understanding of the possibilities, and pushes for real custom work. Or there’s that situation where there’s no acceptable way to work things out with the L J Smith components and a custom fitting needs to be made.

There is need to educate others about the possibilities of solid rail, but I think our market is driven mostly by designer/architects and buyers interested in custom design.

10/29/14 #18: curved stair handail questions for ...

Steve- Very nice 180 and obviously nothing really bendable here, although I’ve seen it done…

Dave’s done it alright, but “gee-whiz Dave,” your non-profiled handrail bend, would be no more than a 4 hour job in solid wood, from start to finish (and without the bending form). Your continuous lam-rail though, is going to be very unique and beautiful. You must admit however, that such bends are almost never practical or possible.

Mike- The day may come when solid curved, handrail segments are as easy and inexpensive to order as regular flat fittings. All you’d have to do is forward your plans to a handrail manufacturer and a multi-million-dollar robot would process your parts and ship them out. Every part would fit perfect and every stick would be custom made. The handrail and joints would be pre-cut and bored for bolts and balusters. Anyway, this is what we’ve been promised at the woodworking machinery shows and probably not an unrealistic potential for CNC. Some spiral stair kit manufacturers have already realized this goal.

When that day comes, only a few die-hards would even consider bending their own handrail. Bending handrail is never going to be easy, inexpensive or even reliable and the fact that bending-rail only bends in a straight line, is also a serious limitation. As an installer, you might have overlooked the actual time and expense of manufacturing bending rail, which is anything but quick and easy. I also think that handrail “strength issues” are more related to poor newel post installations and not necessarily joint weakness. No handrail joints can stay together if the stair posts flop back and forth.

Anyway your crazy, bankrupt and inventive friend, sounds driven and perhaps in what may be a counter-productive way. Without a few “crazies” out there though, nothing would ever change. I was driven (crazy) myself to invent my own handrail profiling machine and have been using it now for more than 25 years. I must admit however, that in the case of at least one of my customers, I was replaced by a robot.

“Open the pod-door Hal”

10/29/14 #19: curved stair handail questions for ...

Dan- Very well said and surely an accurate description of the industry today. Educating builders, architects (and stair builders) is essential and something I've taken quite a bit of time trying to do. Sometimes I feel it's all a waste of time though, very few folks today can appreciate or understand that there is any difference or distinction between standard stuff and custom made. Still it's what I do and all I do.

Fortunately I'm not the only one. There are a few guys like yourself who seem to "get it" and do your own thinking and far from the contents of a cardboard box.

Anyway, this isn't about about educating or convincing others of my particular point of view...I'd truly love to hear from 5 axis fans who are busy making it happen. I would prefer the whole truth though and nothing but the truth. I've already been to the show

Anyway, bend on this...

View higher quality, full size image (408 X 544)

10/29/14 #20: curved stair handail questions for ...

Website: http://www.handrailing.com

Website: http://www.handrailing.com

Jim,

I'm curious about those guys too. I'll be watching.

I often find I'm responding to the issue or question I want to have heard rather than the one that was asked. I know I'm not alone on that one, it's more the rule than the exception.

Take care,

Dan

10/29/14 #21: curved stair handail questions for ...

Jim bending rail can be done with slope changes in one piece (sort of) we have experimented with scarping the slope change into the slats and even cubing the rail. I would hate for the day when a $75 - $150 per hour carpenter is replaced by a multimillion dollar machine( I know I don't have that kind of money to put into a bending machine) but that would be the day that an entire house is built by a 3d printer with no out of square walls and all measurements are to the 1/1000's of an inch.

10/30/14 #22: curved stair handail questions for ...

Respectfully, I think we can discuss machines vs hand, solid vs laminated all day and, while it is enjoyable and illuminating to exchange these ideas, they are mostly arcane ideas and methods. Pie in the sky.

The cold fact is that the customers (as in 'most') are willingly ignorant of these issues, and I think so uncaring, that we might as well be speaking Greek.

Some years ago we had a big customer that complained about the time it was taking to set a straight, raked rail between 2 posts, and hinted that it was the poor quality of the stair parts we sold that contributed. They actually demanded instructions in English and Spanish, to be delivered with each piece of handrail. These houses sold between 150K and 300K. I went out to a couple of their houses and saw $12.00/hr immigrants struggling with new $85.00 chop saws with steel blades, cutting angles with cardboard site made squares, then fastening with one or maybe 2 drywall screws, over-driven until the Phillips head was rounded beyond removal. No plugs - that is the painter's job.

It was all I could do to not laugh out loud. Later, I pointed out to the project managers (there were several) that they needed to up the ante on the skilled labor (as in 'hire some'), and use hanger bolts. I prepped up a sample of the drywall screw rail/post joint and one with a hanger bolt and glue, and passed it around at my return 'report'. They dismissed all my suggestions as too labor intensive and too costly. One manager even was prepared with shear and withdrawal numbers for 'properly driven screw fasteners in hardwood' charts and such, defending what we all knew did not work in practice. If implemented, they concluded, the cost of the house would place them out of the competitive market. They sent me on my way.

Now, before the builder went bankrupt in the crash and he absconded with several millions of dollars that belonged to homeowners, vendors and service providers, they prided themselves on the craft that went into their products, proudly claiming to place the highest values on craft, etc. All just empty marketing BS.

Point is that BS will trump reality within the largest part of our industry. Not within those of us that build stairs, but within our customer base. They choose to believe and say what they want, regardless of the facts or common sense, much less an antiquated (to them) notion of craft and dedication to time-honored methods.

That is tough nut to crack, my friends.

10/31/14 #25: curved stair handail questions for ...

Dave, you sound a bit syndical, frustrated and perhaps angry. "Welcome to my world.". Of course you're right, these kinds of discussions can be pure academics when it comes to actual market conditions but neither your products or mine have any place within 150,000 dollar homes. Perhaps if we'd have both stuck to selling nineteen-cent cheeseburgers we'd both be swinging in a hammock under a golden arch somewhere...But then I wouldn'tbe me and you wouldn't be you.

11/16/14 #26: curved stair handail questions for ...

Hi to Jim and Dave esp.

Love the tread ( pun intended) and thanks for the passion you bring to a really interesting and fulfilling art. I have read all I can find on curved stairs on woodweb, JLC, you tube etc. as I find it a most interesting topic. Just ordered a bunch of reprint books from the late 18 and early 19 hundreds on the subject. Being a trim carpenter for 20 years I have always viewed the curved staircase and radiused vaulted ceilings as the highest level that you could achieve as a carpenter, as I became more skilled I bent many rails out of laminations some pre-profiled and some custom made with router bits. You are always working within the constraints of some material and certain physical limits as to what the wood will actually be able to do. After a while you begin to see when something is actually doable with bending rail and when it calls for a true carved rail. I would lean towards the position that there is a time and place for both. What keeps me excited is the belief that I can gain enough knowledge about the subject to believe that I am beginning to understand the cost, options and method of best practice for a given situation. Being able to talk intelligently and convincingly enough to the customer / architect to have them take my advice to a descision. I enjoy building the carriage as well as the rail and I know that some solid tangent railings are the next step for me to learn and I am excited about diving in and not making any money for a few years till I get it. The CNC stairs that I have seen still needed parts to be jigged, glued up, or placed on a circular form, so I don't see how the next evolution can happen without people like Jim brainstorming on how to convert the tricky math and layout to a repeatable , CNC machinable system. Even though its doable there is a lot of jigging needed to create an organic curving structure where every stair is a one off. So I think the bright point here is the knowledge gained in the overall process. You can't see the forest for the trees applies here as there are many who can see and shape an individual stair part, but it takes someone who sees the whole stair system and the most efficient way to create that item as a whole who will have the most leverage to extract the returns monetarily out of each individual project.

I have been doing a lot of stairs recently that have steel structures covered in wood torsion boxes to make up the stair and they seem to be very popular these days. Not much creativity or knowledge in building them but its what people want and the funny thing is they seem really impressed with what is a very simple design, (insert oh my gosh it looks like they are just sticking out of the wall , how in the world are they string enough to walk on !!!! type homeowner comments here.)

So to me I think its all perception of what is cool, what is craft, knowing the difference and reading people so you know what to sell to each individual customer.

Keep up the good work guys,

I love watching what you do, learning from you and taking the ride.

11/16/14 #27: curved stair handail questions for ...

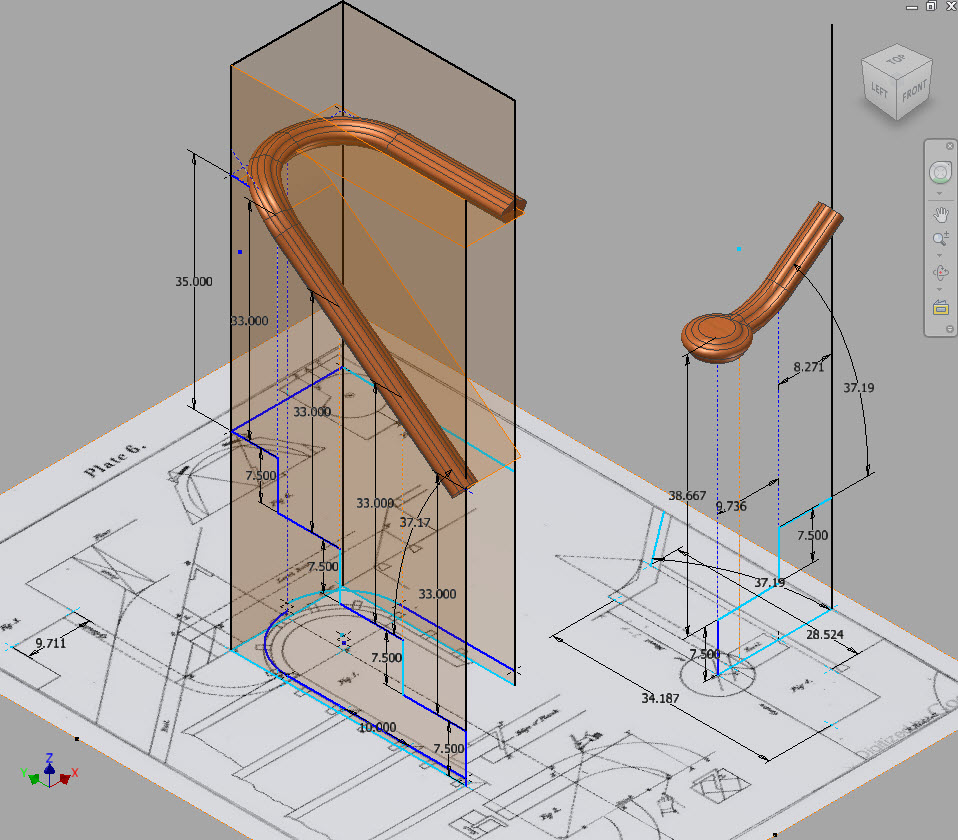

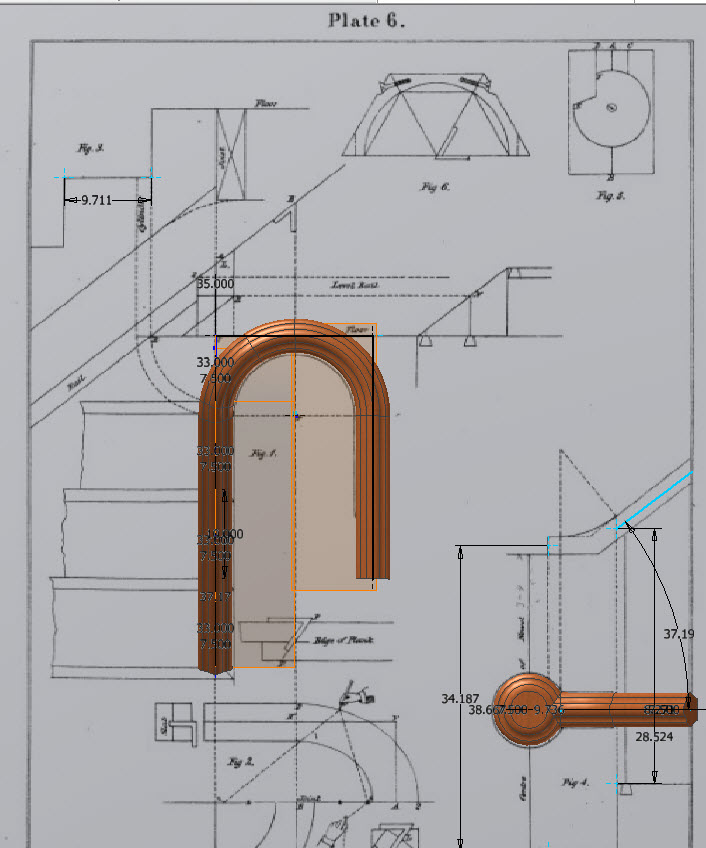

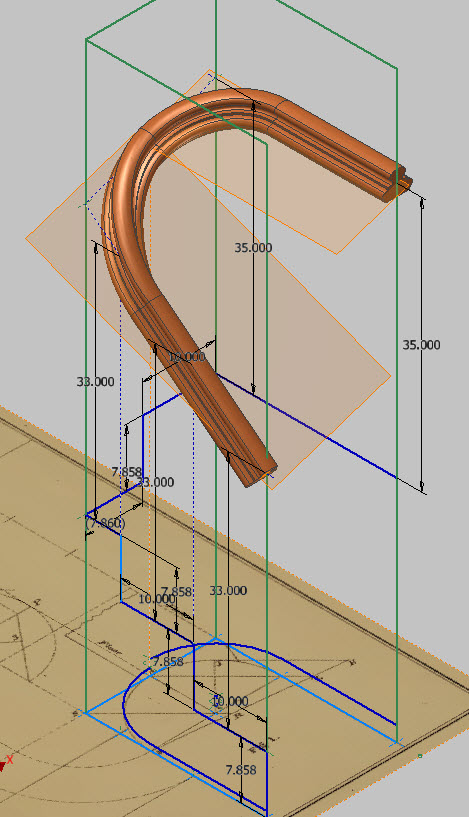

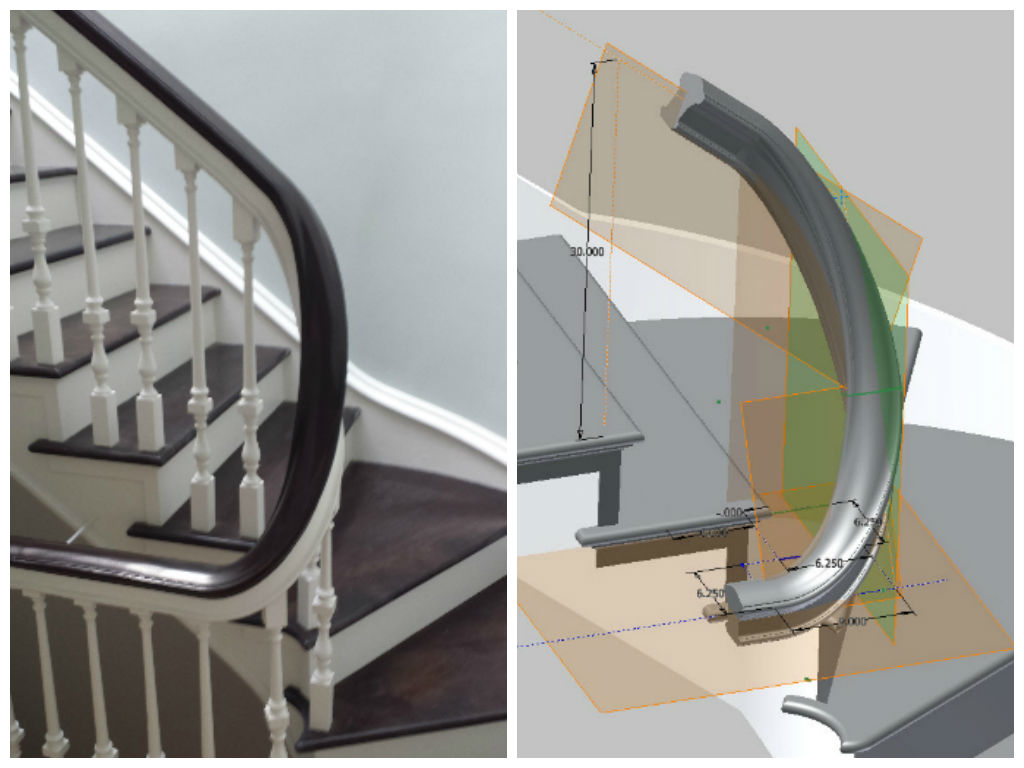

I believe there is a few people out there working on converting old designs and layouts into a modern 3D design and CNC machining environments. CNC machining is just another method, it still takes a lot skills to complete the project.

View higher quality, full size image (958 X 840)

View higher quality, full size image (706 X 848)

View higher quality, full size image (469 X 817)

11/17/14 #28: curved stair handail questions for ...

Website: http://www.handrailing.com

Website: http://www.handrailing.com

Steve,

What is the source of your images? What software to do the 3-D? Is this for rail components you've sourced elsewhere? Your drawing? Whatever the case ---nicely presented.

11/17/14 #29: curved stair handail questions for ...

Dan,

I have a pretty good collection of old stairbuilding books, I find I understand Robert Riddells layouts the most,but I do study quite a few different authors. I can take plates from these old books and create a 3D rendering based on the layout. I choose a handrail profile I like and think might have been used. I use Autodesk Inventor software for all my drawings and then they are used for CNC programming. So if my drawings work , my parts should also work in theory. But I am still learning and practicing on daily basis.... You can see a bunch of my stuff on Linked In.

View higher quality, full size image (944 X 785)

View higher quality, full size image (1084 X 774)

View higher quality, full size image (1024 X 768)

11/17/14 #31: curved stair handail questions for ...

Wonderful drawings as usual Steve and your finished products as well. I guess nobody told you that it's impossible to make wreathed handrail parts on 3 axis machines?

Robert Riddell...really? His drawings and methods seem to change a bit with each of his different books. He also likes to render drawings and instructions based on a specific stair plan (his). These are easy to follow providing you get to build his stair and not the one confronting you from the ignorant architect.

I did get the opportunity recently to produce a pair of Riddell's "side-wreaths". Selling them was the hard part (as Dave truly reminds us of). However once they were installed over a pair of 8x8 Victorian newel posts, they sold themselves. A another order is forthcoming as well as a serious consideration to remodel the stair to accommodate a wreathed transition at the landing. Thanks then, to Robert Riddell and those who've come and gone, but still manage to live on.

I can appreciate the remarks and enthusiasm of JK, Mike and David who are willing and able to try new/old stuff but keep their feet firmly on the floor meeting the real world and real market place. Steve too, however he and I are dreamers. Dan I believe, is also crazy (God help us). Doug knows first hand the folly of all of this.

Still I think if we continue to talk-it-up perhaps we'll find a few more fans and better yet...a few more customers

1/23/15 #33: curved stair handail questions for ...

The thinking of CNC to most people is to throw a router bit profiled to a handrail pattern into the machine and let the chips fly.

In many generic cases, that may work, but to use CNC or robotic technology At the next level, profiled cutters will never create the detail that ball or end mill cutters can create. For my budget, carving and handwork is still the answer.

I used to rough out constant solid radius handrail on a table saw, and then profile the blanks. It can be done if you place the spring boards on your blanks and use them basically as a pilot bearings to run over a dado blade at the proper angle.

That probably doesn't make much sense, I can make it better then I can splain it.

|