Message Thread:

Louver Jig

8/16/19

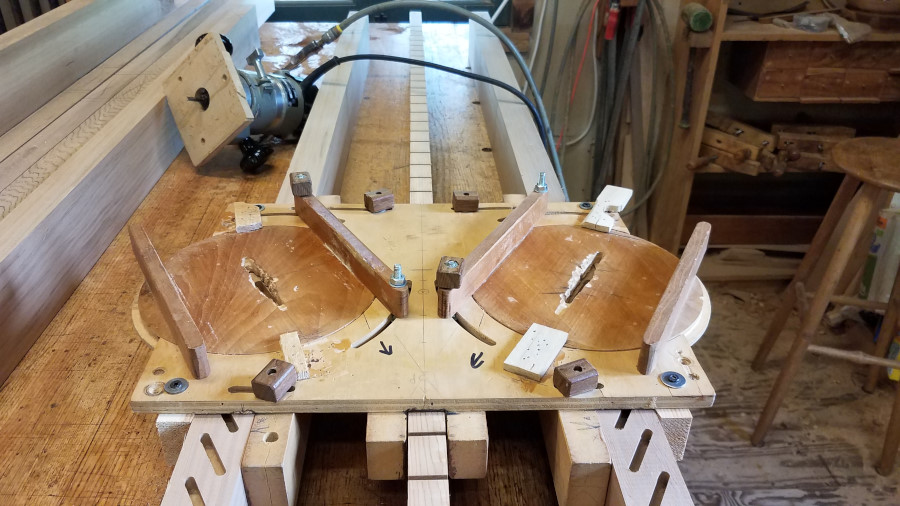

Here are some photos of a little jig I have used for over 25 years to make louvers. It is both sophisticated and quick and dirty. I spent some time building it and incorporated several good features, but reality dictated a few changes on the fly - the dirty part.

I learned to make fixed slat louvers back in the '70's with proper slat routing equipment (A Festo stile router). The jig was made to make several pairs of louvers, and refined for that one use, but then I kept it around and used it a few times a year.

It features the two discs that carry/guide the router. The discs can be rotated to accommodate different slat lengths and angles. Stops are tacked into place (rudely) as needed to regulate the slot length. Guides along the bottom position the two stiles and the center index bar. The index bar has cuts - 1/8" x 1/2" spaced apart to index the jig along the stiles.

In practice, the stiles are laid out with the mortises and the length of the slatted area is calculated. I usually keep my index bars so I don't have to make them again, and then adapt them to each louver job by varying the rail widths. 1-1/2" spacing for 1-3/4" slats is a common one, and the one in the photos.

The index bar is set at the same height as the width of the stiles, and fixed to the bench (nailed). Then the stiles are clamped in place as determined by the jig. The jig has its index bar (1/8" x 3/8" scrap file bar) located to align with the center of the slats. the jig is placed, one side routed (1/4" single flute bit or 1/4" carbide upcut), then the other. Repeat many times. I like to route about 7/16" deep, then after mortising, send the stiles thru the planer to remove 1/16" to clean everything up, leaving a snug 3/8" deep mortise.

A fine point: I like to make one slat mortise about 0.010" wider than the other. This 'loose' side gets all the slats tapped into it during assembly. Each slat is then 'rocked' back and forth a bit to come out of the loose side into the tight side. Into just the opening. A clamp follows along to keep things in place as I worry the slats into the mortises, working from left to right, along the length of the panel.

It can be a long trip along the stiles when assembling, so I recommend something other than yellow glue unless it is the slow cure. The usual glues will all be set up in the rail tenons while you are still playing with slats. You need slow - PU, or plastic resin, epoxy or resorcinol. Assumed the louvers are exterior use.

I never glue slats, by the way.

This jig is a good example of evolved problem solving as well as prudence. A customer wants louvers, I can buy them and probably make more money. But here, my customer sees that I am the answer, not the internet. I get to go thru the jig and try to remember all the little things I need to watch for, set-up, etc. The larger jobs where I am routing slats all day long, make me wonder why I don't buy them, but I soldier on, and the end result is worth it. Somehow I survived.

The job in the shop now, as in the photos, is for 3 pairs of shutters, 6 panels from 72" tall to 98" tall. I have about 7 hours in set-up and rout for the 600 l/f of slat.

View higher quality, full size image (900 X 506)

View higher quality, full size image (506 X 900)

View higher quality, full size image (900 X 506)

8/16/19 #2: Louver Jig ...

Nice to see this. I always look forward to seeing your name pop up on the forum Thanks David !!

8/17/19 #3: Louver Jig ...

David,

Outstanding fixture.

I've done louvers on both my Wirth Machine (heavy duty JDS Mulit-router style machine) and the CNC. While things like the Multi-router and your fixture make for a very satisfying project nothing beats doing a simple CAD drawing and then watching the CNC cut the slots while you do something else at the same time.

BH Davis

8/17/19 #4: Louver Jig ...

After a set-up and about 4-5 hours hooked up to a router, I admit to thinking a CNC would be real handy. Once programmed, it would be a breeze.

Maybe my little jig will end up in a museum, showing the future what the past looked like. I like this jig because it showcases the problem solving nature that I enjoy so much. While slow and plodding (compared to CNC), it is the best solution for any size louver, slat size or angle, spacing, etc.

8/17/19 #5: Louver Jig ...

I would have to agree, the satisfaction of coming up with a jig that works is one of the better aspects of custom woodworking.

The first shop I worked in, during the early 70's, had a louver grooving machine that was old even then. I recall it had a notched metal guidebar about seven feet long that determined the spacing on the grooves. Thankfully I never had to use it, as I remeber the swearing of everyone that did use it.

Many years later, when a job called for mahogany louvered cabinet doors, I made a jig similar to David's, but with less consideration towards future use.

Maybe it is just me, but I would not derive any level of joy or satisfaction in programming a CNC. Yes, it is still problem solving, but the tactile, tangible, hands-on pleasure of an actual jig would be missing, and for me it would lessen that experience considerably. It would be similar to buying a jig.

Perhaps I am just old and in the way, as the song says.

TonyF

8/20/19 #6: Louver Jig ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

This business is hard enough to eek out a living. I agree it's very gratifying taking some wacky idea and getting it to work well, but it's pretty sweet watching a robot do work perfectly with no risk of injury.

Cutting wood isn't the challenge, making the mortgage payment, keeping the tax man happy, and the employees paid is a different story.

8/21/19 #7: Louver Jig ...

Karl - I could not agree more. And hell, sometimes cutting the wood IS the challenge also. Then we still have the tax man, the mortgage, .....

But as you know, I will always take time to set things up in a way that leaves me some enjoyment time. Having this time, where I fiddle with some ancient jig, or design a new one, or whatever, will make me a better human - happy, satisfied and productive. Gawd, I love to see a robot or shaper or molder do what it dos so quickly, efficiently and smoothly. My jig may clunk along yet give me some measure of satisfaction. I realized a long time ago that is what I need - the sense of making, of fundamentally changing the material.

Remembering the jobs I used to have, where it was all drive, drive, drive, I realize how much I missed. How much I never got to play with, to explore and innovate. Not today.

8/21/19 #8: Louver Jig ...

Website: http://Suber Custom Shutters.com

Website: http://Suber Custom Shutters.com

David, thanks for sharing your louver jig. I have a real appreciation for your jig and method of making fixed louver shutters. I too have made several very similar jigs, and still use them on a regular basis. Many of my orders are smaller, and often historical matches, so every order seems to be slightly or drastically different. Louver thickness, width and angle, plus varying stile thickness makes for a lot of setups. Man, you just made my day. 😁

View higher quality, full size image (2048 X 1536)

8/22/19 #9: Louver Jig ...

Mitch - Nice effort. You made my day. The second best thing besides coming up with such a contraption is seeing how others would skin the same cat.

It is one thing to make a jig, but to make it so slat thickness and width, slat angle, and stile size can all be varied is the real challenge.

8/22/19 #10: Louver Jig ...

Nice jigs guys. In view of the effort you went to I hate to admit, my CNC does it when needed.

8/23/19 #11: Louver Jig ...

If there were an available CNC (and programmer) nearby, I'd let them do it. I don't have any great attachment to being hooked up to a router and jig for 4-8 hours. It feels good when you stop, that is about as rewarding as it gets.

As boss, I get to make the jig, proof it, then hand it to some hapless employee that is, for the moment, excited about using this new contraption. So I escape the drudge but get the cream. One advantage of being the boss.

But even so, I would prefer the CNC were it an option. In my neighborhood, all the woodworkers are jealous and protective of their businesses and clients. There is no sharing of beer or cheer amongst us. Why I do not know. I have tried to get together and talk, but all I get are strange looks and negativity.

8/23/19 #12: Louver Jig ...

David, I know what you mean. I tried to set up a group of local wood shops to get together once in awhile, have a beer, BBQ, swap some lies but I failed. For some reason a lot of guys think they have some secret sauce on how they do it. There are only 3 other shops in the area that talk openly with me. I have no secrets. If someone wants to know how I do it I'll help them. Be warned though that my method is likely flawed.

8/23/19 #13: Louver Jig ...

Clearly David and Larry have personality defects and are not affable like myself.

(8^(l)

9/6/19 #14: Louver Jig ...

Some years ago I set up a small group of cabinetmakers. We met once a month, the hosting shop provided dinner. As a group we made purchases (4 beam saws, 5 CNC's) We bought material by the semi truck and split it up, hinges and screws by the pallet. We were hosted some months by material suppliers, others by hardware suppliers. All offered a group discount. We got mill tours and invites as a group, something an individual might not get.

It's now kind of fallen apart because we all got old, some are retired but it was a good idea. Cabinetmakers are basically stupid, they won't talk to each other. They would rather let a contractor rub two of them together and see if he can start a fire. We would be farther ahead if willing to work together instead of creating competition between shops. Going to different shops and seeing how they approached something was the best part. Easy to come home with a good idea.

9/9/19 #15: Louver Jig ...

Bruce - Your co-op group s a great idea - if you can get the people to meet.

Anyone doing this will have to be very careful prices are not discussed or one could be up on Federal price fixing charges.

In Indianapolis, there used to be the Lumberman's Group that met on Fridays for lunch. They started just after WW2 to help each other with the huge demand for building materials. Apparently, prices were discussed regularly and openly.

Eventually, the group changed and aged out, and what was left became an insurance company, specializing in the needs of those in the lumber industry.

9/9/19 #16: Louver Jig ...

The CMA still does that sort of thing.

Bruce's idea sounds good.

Wilson Art and Formica and Nevamar used to get around the pricing regulation problem by meeting in Europe.

Seems like it would be unlikely that the feds would have enough time to chase down a meeting among local shops or if it was illegal at the local level.

9/9/19 #17: Louver Jig ...

Still wish I could pull that of here. When I tried, it seemed like the smaller the shop the more resistant they were. They were afraid someone would steal the recipe to their secret soup. I've seen a lot of the very small shops come & go over the years. Recipes must have been missing an ingredient.

9/10/19 #18: Louver Jig ...

I was very close to a price fixing operation in the concrete business over 20 years ago. The owner of the lumber yard and mill also owned a concrete business. The link has the full story. All the big concrete guys met and agreed to raise prices, then took turns calling the Fed Anti-Trust guys to report what was going on. One Fed agent said there "was a line out the waiting room door" of concrete officials wanting to turn in the other guy.

Money always brings out the best in people. They turned each other in so fast, it made everyone's head spins.

Butch, the son of one owner, granted a TV interview, against his newly hired publicist's advice, where he made the statement "profits were eroding, we had to do something, so I decided to call a meeting."

That got him 18 months. Others did time. One guy spent his time designing his new lake house, which Acorn was glad to supply when he got out.

'Round and 'round it goes.

Tale of Greed and Aggression

9/10/19 #19: Louver Jig ...

Truly one of the most enjoyable and meaningful missives seen on this venue. As always, the Socharisms spawn insightful responses, recipes and all. :)

9/10/19 #20: Louver Jig ...

Good story. Concrete pricing here has long been controlled by the largest operator that also owns the only cement plant in the area. If the other companies don't conform they paid more for their cement. My Dad's company bought a lot of concrete and the only discounts were a small % if paid by the 10th. I don't know if the same situation still exists since I'm long away from that business.

9/12/19 #21: Louver Jig ...

Dave's story illustrates how these laws would be completely nullified if not for the individuals looking to profit from the situation.

The question is, is Antitrust a real situation.

Certainly something similiar to what Bruce suggests is not nefarious.

9/13/19 #22: Louver Jig ...

Anyone in any business that meets with others in the same business has a permanent tightrope to walk. Lots of opportunities for violations. Even a casual remark at the bar over a drink (or 6) can be construed as conspiracy to fix prices. That being of a more innocent nature than that of the terribly impoverished concrete boys and their tale of woe.

I have found that when I am in a rare situation that entails socializing with others in my field, that it is best if I just shut up (imagine that....) and listen. I can re-order drinks, but other than that, I can learn more by just listening and contributing when I can.

9/13/19 #23: Louver Jig ...

I am all ears when you are talking about woodwork.

I wonder if the annual pricing survey could be construed as a transgression against the state?

9/13/19 #24: Louver Jig ...

I will ask Will Sampson

9/16/19 #25: Louver Jig ...

Some years ago, when I was a member of AWI, I was given a pricing guide. This did not have dollars in it, but did have charts and such for recording real timed events in the shop. Make one tenon =x time. Make 2-4 tenons, x-time each. Manufacture to continuous profile - 1 l/f = x time. 200 l/f, and so on.

They also had advice for using replacement costs for materials, and general shop management.

The idea was to plug in your shop rate, and come up with a price for a job, after counting every operation and knowing (from history) what time it took. Extremely cumbersome, I could never use it. But if enough people learned it at a seminar, used it and stayed in touch and compared notes, could they be liable?

9/16/19 #26: Louver Jig ...

David, how likely/easy or potentially possible is it for an operator to make an error with your jig, particularly after the tedium of a half dozen hours, and thus ruin the stile and have to start over making a replacement?

Particularly vulnerable might be the advancement of the work piece for each cut or accurately setting up for the reverse side.

9/16/19 #27: Louver Jig ...

Dave you're missing the point.

As is often the case in this industry one has to put down the magnifying glass and pickup the binoculars.

9/17/19 #28: Louver Jig ...

Yes, I have long preached that a mistake early on is less problematic than a mistake later. Loading a curved stair for delivery presents problems where the complete thing is at some risk. Better to misscut a few parts than to lose the entire project.

"Missing the point"? Oh no, not again. I have that as a fault - looking at the wrong thing, or the wrong end of the binoculars. I was never good at making money. My strengths lie elsewhere.

View higher quality, full size image (2592 X 1944)

9/17/19 #29: Louver Jig ...

The antitrust yik yak is specious and benefits no one

9/17/19 #30: Louver Jig ...

I do respect your woodworking skill

|