Message Thread:

Custom Furniture at a Cabinet Shop

4/10/20

Hello Everyone,

I'm new here, and thanks in advance for your input and time. I'm currently in school for something completely unrelated to woodworking but I'm an entrepreneur at heart.

I was hoping I could get some insights from the members of this forum on some business/technical(machining) topics that I don't fully understand and could use a hand with. I spend a lot of my personal time woodworking in a small garage shop with non-industrial tools (and so I have a decent understanding of wood manufacturing language/principles) and in my other free time, I've been working a lot in CAD designing furniture.

I wanted to try and meld these two things together into a small start-up business.

My goal is to produce the designs and find the customers, while (at least in the beginning) finding a local partner who can provide the manufacturing and packaging. At this point, my designs require a 3-axis CNC machine that can accommodate at least 4x8 sheets of 3/4" material and switch between at least 2 tools (cutting bit/saw, 5mm/8mm drill bit) and an ability to efficiently edgeband (likely with an edge banding machine).

I was thinking that I could try and find a mid-size custom cabinet maker in my area to partner with. My value proposition is that I'm not directly competing with them, while providing them with flexible work they can do to generate revenue when their machines aren't otherwise being used. They have no additional upfront costs, other than perhaps material management/warehousing. I would provide the work-orders in large-ish batches with flexible completion schedules.

I would provide all the CAD/CAM files with tool paths already planned for their machines, their only job would be to run the scripts, handle the material and package the final product.

I was hoping I could ask a few questions and get your input...

My business questions are:

(a) Do you think I could find a cabinetmaker who would find this appealing? If not, can you think of a better way for me to approach my manufacturing? (as a student, I don't have the capital to set up my own shop... yet, and in any case I don't mind operating with net-0 profits at first to show marketability)

(b) What do you think a fair per-piece (entire piece of furniture) manufacturing and packaging cost would be if I could provide, say, a minimum of 300 4x8 sheets worth of orders to be cut? [I'm trying to see if I can get my product into a reasonable price-point for my target market; IKEA shoppers and the like]

My technical questions are:

(c) I've never done a lot of edgebanding. Can automatic edgebanders apply veneer to non-square pieces (e.g. a parallelogram). As a part two to this question, even if you have a square piece, can an automatic edgebander apply veneer to, say, the 8" section of a 6'X8" piece? If no to both of these, how do shops generally apply veneer in these situations? I've looked everywhere and am having a hard time finding information for beginners on the more advanced manufacturing machines.

Thanks everyone for your time, it's appreciated!

4/10/20 #2: Custom Furniture at a Cabinet Shop ...

Before I retired, I'd guess I had at least 20 people over the years approach me with this great and huge money making opportunity. If I could just make a couple samples at a discounted price, the ball would get rolling in not time. When I was wet behind the ears, I did that a couple of times. Made the samples, passed them over, and never heard from them again. After that, I would not discount anything, and again I never saw them again. I did accept one job making one hitter boxes, and even that turned out badly. Who would ever guess a guy making one hitters and wanting wood boxes would be a horrible business person? Right? You better find a fresh owner, the rest will be gun shy to your approach. Best of luck to you.

4/10/20 #3: Custom Furniture at a Cabinet Shop ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

"No up front costs" Machines aren't free, tooling isn't free, floor space isn't free.

a) No. Better way? The same way virtually everyone here started out. With minimum equipment and a lot of time spent getting not much done. But, it's a way to make it happen.

b) Too many factors to give any kind of accurate answer. I charge $32 per program cutting parts on the cnc for normal cabinet box parts. It goes up from there typically unless it's something REALLY simple, like a circle. That doesn't include material.

c) I don't know of a bander that will do angled materials. It might exist, and I don't know about it. Anything square is standard though. Profiling banding requires a fancier machine than we have. We haven't done any banding work for anyone else, so I don't know what to charge for that.

If you came to my shop, I'd entertain it, but I wouldn't do anything on spec.

4/10/20 #5: Custom Furniture at a Cabinet Shop ...

Website: http://thomasdiel.com

Website: http://thomasdiel.com

Your also making a huge assumption that your post (CAM output) works with the shops router. Many years ago I white knuckled first runs of others programs with the feeds turned down really slow, right hand on the E-stop after running all the z- G-code checks and checking the drawings in 3D to visualize the tool paths and running simulator toolpath programs. Its not worth the headache or possible crash. Your not bringing anything to the table, sorry but I would not let you do it based on you post.

If you befriended a shop and buddy up with them over a long haul & everything goes smoothly (not likely) your still looking at router time and initial programming time but that would be a one time hit and then cycle start and your making your widget.

Best of luck, TD

4/10/20 #6: Custom Furniture at a Cabinet Shop ...

Website: http://thomasdiel.com

Website: http://thomasdiel.com

Sorry I forgot the edge banding issue, but I lost you, can you do a drawing or pic?

Not to quash your efforts but every shop, and their set-ups are different. Too many variables that you have to know before anyone is going to let you program like: running big iron 16hp spindle w 40hp vacuum running 900ipm in small 100sqin parts w -.003" through cut in one pass. Or are stepping through & reversing cut direct for optimal cut quality? You could onion skin or tab due to lack of vacuum or material porosity. Not to mention material i.e. internal tension of import ply & climb cut CCV three flute 3/8"dia compression bit or man-made sheet 1/2"dia compression conventional cut or can you get by w a rougher? Machine feeds and speeds paired with the right cutter =chip load = cut quality that is dependent on the machine's bells and whistles and in depth knowledge of the programmer and the shops procedures.

I recently sent out drawings to be routed and had line segments under polylines. My bad, the guy thought I was a rank amateur I'm quite sure. The project had been released after two years and I didn't double check, erase, and explode everything, so the sudden halt was on me.

If you find a shop willing to entertain your concept, my suggestion would be to ask them their strategy, study the solution and then ask to watch it run. Lastly, cut them a check for the balance due.

4/11/20 #7: Custom Furniture at a Cabinet Shop ...

300 sheets at ~$30 per piece and ~$30 for cutting it per piece gravitates toward $270K, not including edgebanding, assembly, hardware, packaging and God knows what else.

For that kind of money you could rent a shop, buy yourself a cnc and an edgebander and try it for yourself with 150 boards for start instead of 300.

4/11/20 #8: Custom Furniture at a Cabinet Shop ...

Hello,

Thanks for the replies!

@rich c. Point well taken. I am not asking for samples, however. My goal is to get a pre-order that leads to a production run big enough that it’s beneficial to the shop owner to work with me. I believe the high quality digital renderings I have should be able to generate enough interest, subject to exactly how many it takes to ‘create interest’ for a manufacturer.

@Karl E Brogger Thank you as well. I said “no *additional* up front costs”. A shop’s fixed costs, including equipment and rent, are going to be the same whether they work with me or not. Rather, what I mean when I say additional costs is I’d like to pay a shop for any variable costs in addition to a fair market price for their existing infrastructure.

Which leads me to thank both of you again, it’s great to hear your perspectives on this, which seems to be a resounding “probably not but maybe if you did it the right way and made it worth my while”. It sounds to me like “worth my while” is a sufficiently big order with sufficient compensation, and that’s part of what I’m trying to figure out: how much furniture would I need to have pre-ordered to make it worth someone’s while?

@ Thomas M Diel Thanks for pointing out the CAM stuff. As I’ve not owned a CNC, it’s great to hear what you have to say on tool pathing. I’m working in Fusion 360 right now, and with what I’ve read it sounds like I’m able to create safe predictable tool paths for many different machines, although I’ll be sure to figure it out if I do end up finding someone to work with.

Regarding the design, it’s great to hear the headaches you are talking about, because my goal is to create furniture designs that are driven by the manufacturing process, rather than having a design process and figuring out the manufacturing as an afterthought. There’s a lot of guys out there with ideas in their mind of what they want their furniture to look like, but not many know how hard it is to build it and do it efficiently, especially if you want to offer any customization. I want to take a stab at finding a balance between manufacturing simplicity/functionality and style that accounts for exactly the types of things you are talking about, and I think that I have some solutions that just might be able to bring something new to market.

@ Oggie, your pricing seems in line with what Karl said, so it’s good to see consistency. Could you clarify “per piece”? If I had 4 furniture designs, and 100 orders of each furniture design that each reaquired ~ 2 full sheets (4x8) of material (400 pieces and 800 sheets), would that be $30 per piece on the sheets, or $30 to cut each sheet? At 800 sheets that need to be cut, do you think the economies of scale would bring it down? Regarding the rest, I have assembly, hardware and the rest mostly sorted, although I do still need to figure out packaging.

Again, thanks all. If other people have comments on this I’m open to hearing them…

Have a great Easter weekend!

4/11/20 #9: Custom Furniture at a Cabinet Shop ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

I always build first one a full price plus. then discount the remaining

4/11/20 #10: Custom Furniture at a Cabinet Shop ...

You haven't mentioned the real problem - why would anyone buy from you? You want to compete directly with IKEA? Good luck with that. You would need to look mighty credible to even have a chance. And don't dream of competing on price - the people who are too broke for IKEA are not your ideal customer.

So many people think that the constraint in custom furniture is manufacturing. It isn't. The constraint is finding a steady stream of paying customers, and then establishing an operation which will be able to separate them from their money, and deal with the inevitable delivery and repair issues along the way. The number of people who will want whatever you are selling is likely to be very low, and they will be spread all over the globe. How do you deal with that?

Furniture is not at all like a restaurant. It's not a word of mouth business. Your customers will buy once from you, if at all, and you'll need to replace them on a regular basis. Making each sale will take significant time (unless "custom" doesn't mean custom anymore.)

Hate to pee in your cheerios, but before you sacrifice whatever money and time you have on hand, start thinking about these issues.

4/11/20 #11: Custom Furniture at a Cabinet Shop ...

am i missing something?

300 sheets at $30 ea plus $30 ea for cutting is $18,000.

how do you get 270K ?

4/11/20 #12: Custom Furniture at a Cabinet Shop ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

He went 30*30*300= 270,000.

It needed to be (30+30)*300=18,000

4/11/20 #13: Custom Furniture at a Cabinet Shop ...

@ Paul Downs

Thanks, I think you are right, I would never try to compete with IKEA on price piece-for-piece. However, would people pay an extra 30% for a piece that fit perfectly? Likely, or at least I like to think likely.

And don't worry about peeing in my Cheerios, it only makes sense. In fact, it's the reason I'm here, I want to try and get an understanding of what my costs are going to be (approximately), and figure out if it's worth the time to keep putting my effort into. I agree with you that acquisition costs are huge in the furniture industry, but I also think that online ecosystems can move away from that in a way that is changing the wood manufacturing space. Think Uber and Lego had a baby. There's a couple of businesses I've seen doing something similar to what I'm trying to do, and they are seeing some moderate success and I think I have a way of doing it that's better than what they are doing.

But that's my ego talking.

@ Dean C

@ Karl E Brogger

I think he meant $18,000 as well. And that's a total I can work with. If I was a cabinet shop owner and someone came and said "I'll give you $18,000 to cut these 300 sheets for me" I think I'd say yes, subject to of course how well I'm able to make it easy for them (tool pathing etc.)

Thanks again all, and still always curious to see what others think/say, I don't think there's such a thing as too much experience even if my Cheerios taste funny....

4/11/20 #14: Custom Furniture at a Cabinet Shop ...

Colin

Here's some advice you probably don't want to hear,you say your a student, stay in school!.

As part of your education ,Buy Paul Downs book ! I wish I read it in my 20's.

You say something completely unrelated to woodworking?.

Well what is that major? Hopefully an MBA?

You don't have to be successful in woodworking to have a successful woodworking business.....

Making anything is the easiest part .

After you find this person to machine all these parts,

Where are you going to store them?.Transport them to? Space to package and ship the product?

I can machine a couple hundred sheets a week.

I know if I cut up a 100 sheets,which i would not !-Small batch processing !

I am going to load up 20+ Hafele carts or 15 skids of material.

2000 sq.ft.+ floor space.

It's not going to be at my facility!

Space is the most valuable resource I have !

My education,LOL, a father and an uncle who did carpentry, cabinetry.Graduating Vo-tech School in the mid-1970s.

Went to work in a cabinet shop that was in a chicken coop, bought him out two years later when I had that entrepreneurial spirit.

In 1981 I was approached by a gentleman with an idea like yours, video games?... Sure I played Pac-Man at the arcade...

Rich C. thoughts echo..

Could I build cabinets for video poker and blackjack. Well over the next 3 years I made 7K's worth of boxes.

All with just a Safety Speed panel saw and a Rockwell R9 pin router.

Education By FIRE !..

I could machine all those parts now in a month ...

Hopefully When this Covid 19 dilemma has a vaccine and we are back to almost normal,

I say get a job in a Cabinet shop this summer,

We are all looking for someone with a brain!

4/11/20 #15: Custom Furniture at a Cabinet Shop ...

What Paul Downs said.

The number 1 thing in business is marketing not sales.

If you want to get a better idea about things I would look hard at what the competition is doing, if there is no competition that is a bad sign.

IMO most business (cept retail maybe) change their marketing plan after they are in business, IOW they rarely stay in the same business they started out in.

Entrepreneurship is about having knowledge that most people are not aware of regarding what people consider to be valuable.

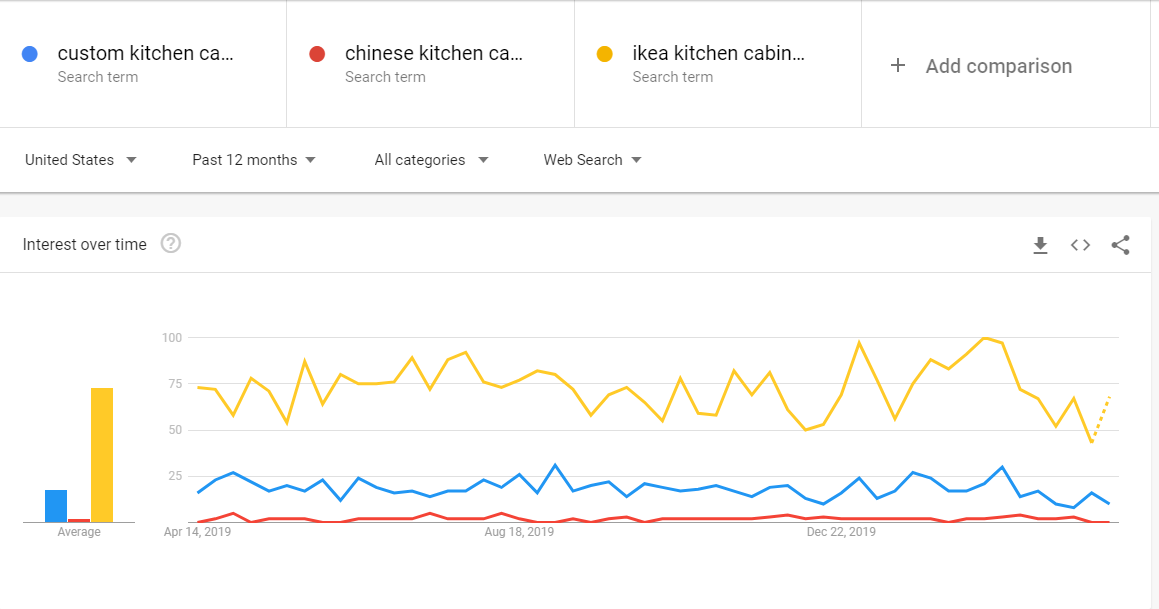

If you go to google trends it is somewhat useful for marketing. see the chart (gotta have charts)

One of the most valuable insights into this is discovering what is the emotional reason people have for buying something. E.G. people who buy Paul's tables might think of his tables as an investment as well as a status thing(this is an emotion), people who buy from Ikea want to save money (this is an emotion), people who buy a new kitchen for their existing house because the lady of the house is tired of looking at the same kitchen (in many cases just the color), the husband thinks happy wife happy life. (this is an emotion)

The key to this subject is surveying people who are the customers of this type of business.

Steve Jobs used to say that surveying is a waste of time, I can see this point if Henry Ford would have surveyed people they would have said we want a faster horse. But unless you are designing furniture that is revolutionary surveys will be useful.

You might want to run a craigslist ad for $5 to gain some information or find people to do surveys on.

Have ever you do it you need to find out about the market for your product.

Surveys are less painful than peeing on the electric fence. None the less people usually say yeah but I already know, according Socrates that means they don't really know. e.g. how many times have you seen people design their logo or company name based on THEIR emotions, the customer doesn't care about what the owner thinks.

View higher quality, full size image (1159 X 609)

Google Trends

4/11/20 #16: Custom Furniture at a Cabinet Shop ...

"would people pay an extra 30% for a piece that fit perfectly? Likely, or at least I like to think likely." What do you mean by fit perfectly? I would have gone bankrupt on a 30% markup on IKEA, and their product seems to fit a very large demographic. Heirloom quality will mean even less as people climb out of this recent hit. The job market will be more volatile than normal. This means professionals have to be flexible. Moving every 5-10 years will be common. Those aren't thoughts that will make people buy lifetime heirloom quality. A life of 10 years for their furniture will be good enough. How will you market your product is worth the extra over the other thousands of shops and product lines? EVERYONE markets their superior product and customer service, even IKEA.

4/11/20 #17: Custom Furniture at a Cabinet Shop ...

It might be a good market to install Ikea for people?

4/11/20 #18: Custom Furniture at a Cabinet Shop ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

Installing Ikea is like pounding a turd into a rock.

Maybe you get good at it, but I've been frustrated the few times I've done it.

4/11/20 #19: Custom Furniture at a Cabinet Shop ...

I have installed a few Chinese Kitchens (pre Rona) it wasn't too bad. Ikea I would think would be better.

Anyway just a question, the demand appears to be high?

4/11/20 #20: Custom Furniture at a Cabinet Shop ...

Sorry for the number mistake, I accidentally hit * instead of + and it was too late in the night for me to wake up my brain from 'idle' mode.

Anyway, regardless of the numbers, the 'business' side of things others were talking about are much more important.

I am inclined to believe that most of us ended up here not by having great plan that succeeded but mostly by being stubborn and physically and mentally strong enough to continue even when that first plan turned out to be naive and possible even stupid.

4/11/20 #21: Custom Furniture at a Cabinet Shop ...

As far as installing the ikea cabs, this guy has the right idea i guess..

https://www.mensjournal.com/gear/semihandmade-john-mcdonald-kitchen-cabinets/

4/12/20 #22: Custom Furniture at a Cabinet Shop ...

@ Tom C

Thanks, I'll order Pauls book it looks great. Cool @ Paul Downs that you are here too, and thanks again for the comments.

I am getting a legal education, not exactly an MBA but a lot of useful skills. I grew up working in my own family business as well; restaurant industry.

@ Pat Gilbert awesome advice on the surveys and google trends, hadn't thought of that!

@ rich c Thought you would get a kick out of a company called TaskRabbit doing exactly what you said, they are worth multiple millions now and have a contract with ikea...

https://www.taskrabbit.com/

The fact that people will pay between $60 and $120 to have someone assemble some ikea furniture (and made a successful business out of it) makes me think some Ikea shoppers aren't as broke as we might think at first, and that a reasonable markup wouldn't necessarily be successful, although maybe only 30% is ambitious.

I'm not aiming for heirloom, I'm aiming exactly for the type of market you are suggesting. People who can afford to buy new furniture, but who can't afford heirloom stuff.

Here's the story that was the inspiration for what i'm trying to do: I needed a bookshelf to fit next to my desk (i'm looking at it right now). We measured, and off to ikea we went. Cool, a Billy bookshelf for $79.99! But it's only 48" I need 64", so then we bought the slimmer add-on version as well, only $59.99..., then I needed the height extender ($39.99 and 29.99) to maximize the space in my 600 sqft urban apartment. Didn't feel like such a bargain when the whole unit ended up costing north of $200, and there is a bunch of redundancy in materials and hardware. Plus it looks like lego pieces and the height extenders rack against the main pieces. I would have paid $250 to get a piece that's easier to put together and didn't look like it was cobbled together. If it was manufactured and made of locally sourced materials too, that especially wouldn't hurt. There must be a better way...

4/12/20 #23: Custom Furniture at a Cabinet Shop ...

Website: http://www.kdunphy.com

Website: http://www.kdunphy.com

Boxolagist : meaning low skill worker ,will work for below min wage thinking they have a future as there own boss .But they get more in debt

Get experience and experience .The guys that are posting have made it listen

Its hard to handle a sheet in a small space

4/12/20 #24: Custom Furniture at a Cabinet Shop ...

Colin,

What everyone here is trying to say, is that you simply have to dive in and do it. Your journey will be unique and it will be yours.

I personally would run some parts for you because I like young people interested in the business. You may have to wait a while till I have time, but I'd do it .

I started just like Carl said, lots of work not making much money. But I was stubborn, believed in myself, made 1000 mistakes to learn how to do it right. That will be your journey too. Perhaps you have a million dollar idea, you bring it to a shop and that guy , with the equipment sees your genius, takes your idea and runs with it. Or perhaps you find an ethical owner who runs parts for you at a fair rate and you both make money. Your legal degree will be of good use.

In any case it will be your story, your journey, and I hope you find joy and fulfillment along the way.

4/12/20 #25: Custom Furniture at a Cabinet Shop ...

Woodworking has over the years drawn many, many individuals that come to it thinking cheap and or easy. For some reason, our craft is viewed by others as not very difficult. The fact that most people have a hammer and can buy a power saw means the threshold is very low, so there are no barriers. Why not ?

I'm developing a Corona virus vaccine in my kitchen. I have test tubes, one of those spinning thingys, some bad smelling chemicals, plenty of time, and the market is huge. I think I will partner with some young, tech like person to make that side easy.

No disrespect, but you did succeed in getting the collective ear of the top people around here. They agree your plan is deeply flawed. People in the industry long term will tell you what you have already read - this is all so much deja vu.

Sorry about the Cheerios....

4/12/20 #26: Custom Furniture at a Cabinet Shop ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

Do some research on how Ikea does things. A lights out operation is very different than what most of us are running for shops.

They've spent a lot of money automating everything. I bet a handful of guys move more dollars in a week than my shop does in a year.

The point is, I couldn't come close to building anything Ikea does for the cost they do. At least not sustainably at a business level. That's a wicked hard market to compete with.

4/12/20 #27: Custom Furniture at a Cabinet Shop ...

This is an interesting dichotomy between the enthusiasm of youth and the wisdom of age.

Acquiring knowledge can be painful but you don't have to pee on the electric fence to gain knowledge.

With wisdom often comes the burnout the loss of "the illusions" the slowness to reach for the next thing, go into retirement.

Everybody here started out with enthusiasm and some/most still retain it.

I doubt Colin heard a fraction of what was said on this thread, OTOH hold onto that enthusiasm Colin.

4/12/20 #28: Custom Furniture at a Cabinet Shop ...

All right, we've slapped this guy around pretty good. On the other hand: If I had told all of you my plan back in 1985 it would have sounded even less plausible. And here I am today, 35 years later, with my shop and my employees and my clients and my business. A lot of success is luck, and much of the rest is simply refusing to shut the doors. Who can say whether OP is doomed to fail? He'll just have to try and see what happens.

4/12/20 #29: Custom Furniture at a Cabinet Shop ...

Colin,

Contact www.panel.com most of all they do is panel processing and edge banding for other people. Pick their brains you'll learn a lot. They return quotes quickly also.

I know of some small panels processing companies that charge $40-$70 a sheet for machine time, depending on the difficulty, there should be a few near you.

If you're gifted in design and marketing the manufacturing is the easy part. I have worked for a $30 million, $500 million, and a $2 billion company that was started by women that still know nothing about manufacturing and the primary product is furniture and home decor products.

If you're going into the furniture market you might want to visit High Point Market https://www.highpointmarket.org/ it's the best place to get an overview of the industry. 2000 furniture manufactures show there, and over a billion dollars in orders are taken there in 7 days.

4/13/20 #30: Custom Furniture at a Cabinet Shop ...

Colin,

If you haven't already, read various articles about Greycork and glean what you can from their quick rise and why they crashed and burned.

4/13/20 #31: Custom Furniture at a Cabinet Shop ...

Collin,

Here's a good article about GreyCorK failure. https://www.fastcompany.com/90110086/the-elusive-dream-of-affordable-flat-pack-fur

niture

Blue Dot is a better example of a successful startup furniture company and they started right out of college at around your age.

https://www.bludot.com/connect/our-story/

4/13/20 #32: Custom Furniture at a Cabinet Shop ...

That Blue Dot story is interesting, made in the USA, they look like Warby Parker types

I noticed that a couple local successful companies shut down 2 years ago. One I toured their shop a long while ago, super efficient and practical setup for making bedroom furniture at that time IIRC they were doing 30 million and later grew to 60-70 million. Here in Calif CARB country.

Another was an unfinished furniture store that had been around since the 1950s.

Neither were causalities of offshoring that happened here in So Cal a long time ago as in 2nd only to N.C. in furniture manufacturing.

At the time I was installing cabinets all around So Cal, the thing that struck me was that NONE of the cabinets were stained but almost all painted.

My theory is that these companies became complacent on the finish.

The market is always changing, IMO complacency predisposes one to becoming an anachronism, don't ask me how I know that.

4/13/20 #33: Custom Furniture at a Cabinet Shop ...

Hi All,

@ Robert and @ Pat Gilbert,

Thanks this was the kind of advice I was looking for. Very cool that there is an entire national company whose business model is manufacturing pieces for businesses who don't have their own equipment... I hadn't come across them.

I've also read about Greycork and its success and failures. Cool company and neat idea, too bad they went under. Fortunately, they are not what I want to emulate, although obviously there is overlap. I liked the final line from the article:

"We’re getting closer with each attempt to change the system, but consumers who want nice, easy, inexpensive furniture that isn’t Ikea will likely have to wait a little longer." <- it's been 5 years.

You guys should check out tylko.com they've been running for 5 years out of Poland. They aren't affordable (although they say they are), but 5 years continuous is a success in my book, but I still think it can be done better.

@ Quicktrim that's a very generous offer, and thanks for your sincerity.

To everyone else thanks for your time too. Some of the negativity felt a little unneeded; I didn't exactly publish a treatise on my business idea for everyone to read, but there nonetheless seemed to be a lot of assumptions made about things I allegedly didn't think about when really I just didn't talk about them in my posts. I never used the words cheap or easy to describe how I would try to make it in this industry, and it was never my intention to make it sound as if I knew it all or could do it better despite having never done it. I came seeking advice and perspective and I guess I did get a lot of that so thanks! It's not on deaf ears.

When I've got my first production batch going or the website up, I'll share it here for a round two of discussion... and I'll check back from time to time.

Good luck to everyone with COVID-19 and the rest! You seem like a bunch who know how to persevere.

4/14/20 #34: Custom Furniture at a Cabinet Shop ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

Colin, lose the thin skin. Nobody said anything negative that I saw. What you've gotten is the view from people in the trenches. We don't participate in this forum to have our egos stroked, or to blow smoke up each other's rear ends.

We're all here to do the same thing. Pay the mortgage and keep the wolves away. We've all failed in one way or another and learned from it.

What you want to do is certainly plausible, thousands of companies outsource most of what they do. I think you are on the right track in talking to a smaller shop that has some excess capacity. They are going to be more flexible than a larger company. But keep in mind, that shop owner is likely pulling his hair out from working twenty different positions within his company, and he's not going to float anything. Parts get cut, then they leave more or less immediately. Small shops rarely have much spare space, and that owner isn't going to tolerate much disruption to their work flow.

I did want to re-affirm what somebody else already said about cnc work. Nobody with any sense is going to run a program anyone else created on their $120k machine/baby/moneymaker. A good portion of the machines out there won't do it anyways, as they don't run off straight G-Code, and function in an environment.

Also to parrot other's comments, building stuff is easy. Selling it is the tough part.

4/14/20 #35: Custom Furniture at a Cabinet Shop ...

Colin,

Maybe a little different perspective here from a smaller varied shop that does a good bit of prototyping and odd-ball parts while also operating on our own in a varied mix of commercial cabs, tiny bit of retail, furniture, and architectural millwork and interiors.

The question of being able to find a shop to entertain your work is just what it is, you may find one, you may not. I dont prescribe to the standard response about prototyping here, the "make me some based on future business". If someone was fool enough to do that so be it. My initial prototypes based on customer supplied drawings are billed at shop rates (read the initial parts are in-sane expensive). Im not making prototype number anything for free. Anyone who is serious and has confidence in their product/item will usually state clearly that they fully intend to pay for prototyping.

I have three very lucrative production runs for various companies at the moment. Of course I could get clipped at any second by another shop or outsourcing but I made my money on the prototypes and I'll cash the checks while they come.

My perspective personally is if you feel you have an item/line to move forward with you've likely done your market analysis and feel you have a product worth pursuing. With the way things are today you can contract with a shop anywhere and other than the cost of shipping prototypes and product, while it would be handy, they dont have to be local or even remotely local to you. They can be 2000 miles away and you never meet face to face. Have at it.

Im sure youve spreadsheeted the whole thing out and youve gotten a decent range of numbers for per sheet processing already but other packaging, shipping damage, and so on, may play a factor.

We just signed a ND and DNC with the third we are running parts for happily. Im more than happy to be sitting in my shop making parts and paying my bills while someone else comes up with the ideas. Likely a million ideas tap me on the shoulder daily but Im to busy trying to keep the shop running to even notice them. For one to stick it would have to be like an anvil falling on wil-e-coyote's head for me to even pick up on it. So I leave it to people like you.

Good luck

|