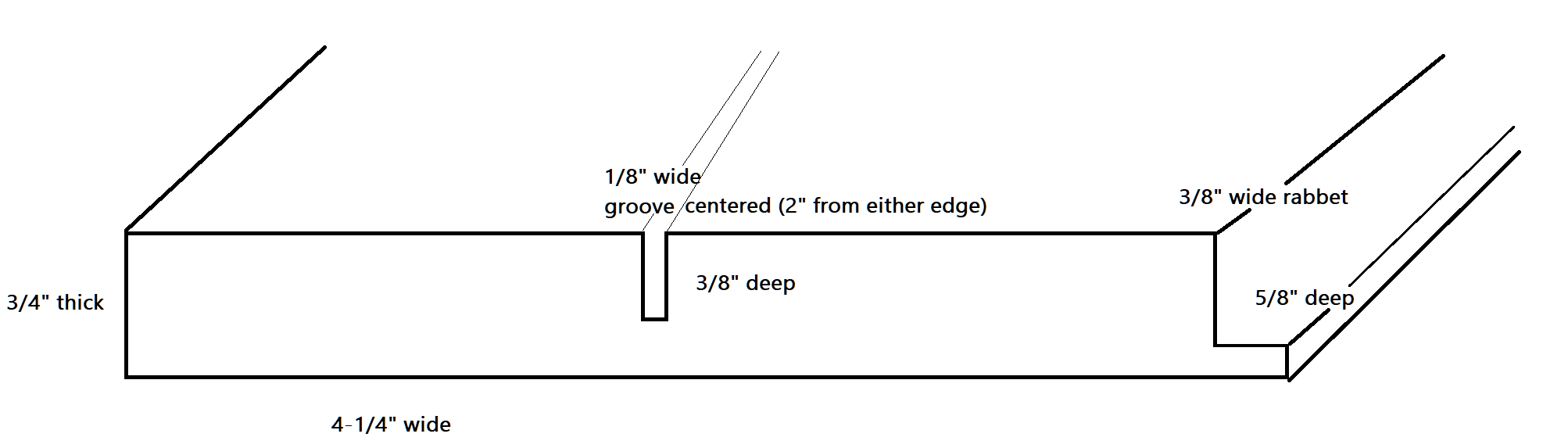

We're looking to lean up/improve the way we groove our toe kick boards. We use leg levelers, so our toe kick is 3/4" thick material with two grooves on the back. The middle is just a 1/8" kerf cut for the toe clip to be hammered into, and the top rabbet is a notch to avoid hitting the leg socket's top flange.

I'm trying to figure out how to cut both grooves in one pass. We're going to set up a single tablesaw or router table with a power feeder to do nothing but groove toe kicks. We have several major projects about to hit and we're going to be grooving a few hundred linear feet per day of this.

My three options seem to be:

1) Router table and power feeder using a box joint bit stacked just to cut these two notches, or perhaps a custom router bit.

2) Tablesaw with power feeder and use a dado stack, except with spacers between the two grooves. I'm actually skeptical that our old Unisaw has an arbor long enough for this.

3) Williams and Hussey benchtop moulder with a custom blade. The downside here being HSS knives. We groove a LOT of melamine here and those HSS knives are going to take a beating. The cut doesn't have to be particularly pretty since it's never seen but I can't imagine HSS not being wrecked after a few thousand feet. A carbide saw blade will go for most of a year without needing replaced.

Either way, the goal is to cut these the exact same with presicely 0 machine setup other than safety checks. Any suggestions?