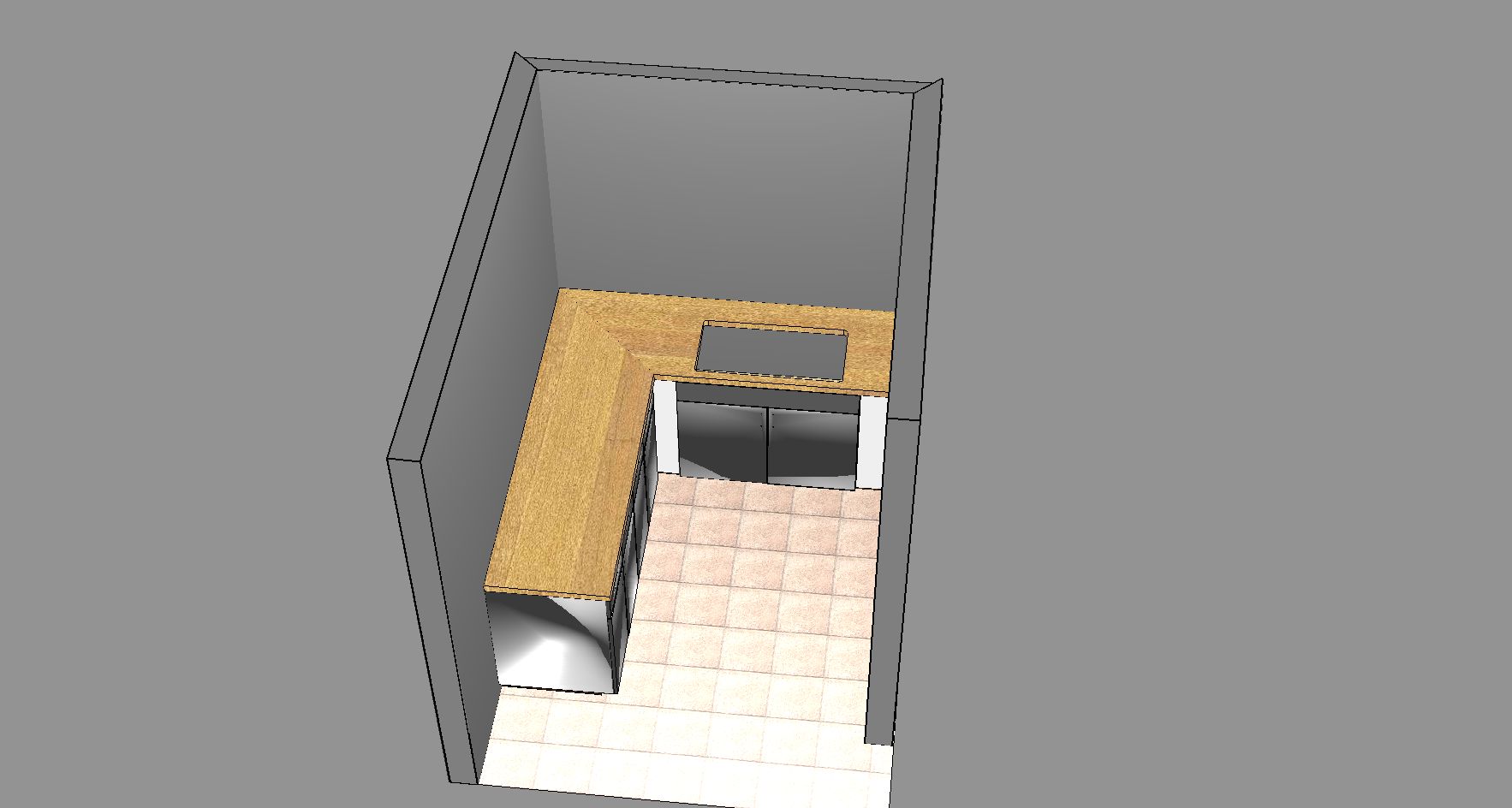

The general feeling about mitered tops is to not do them. There are occasions when you must do them to accommodate the Architect, Builder, Customer or your own personal goals.

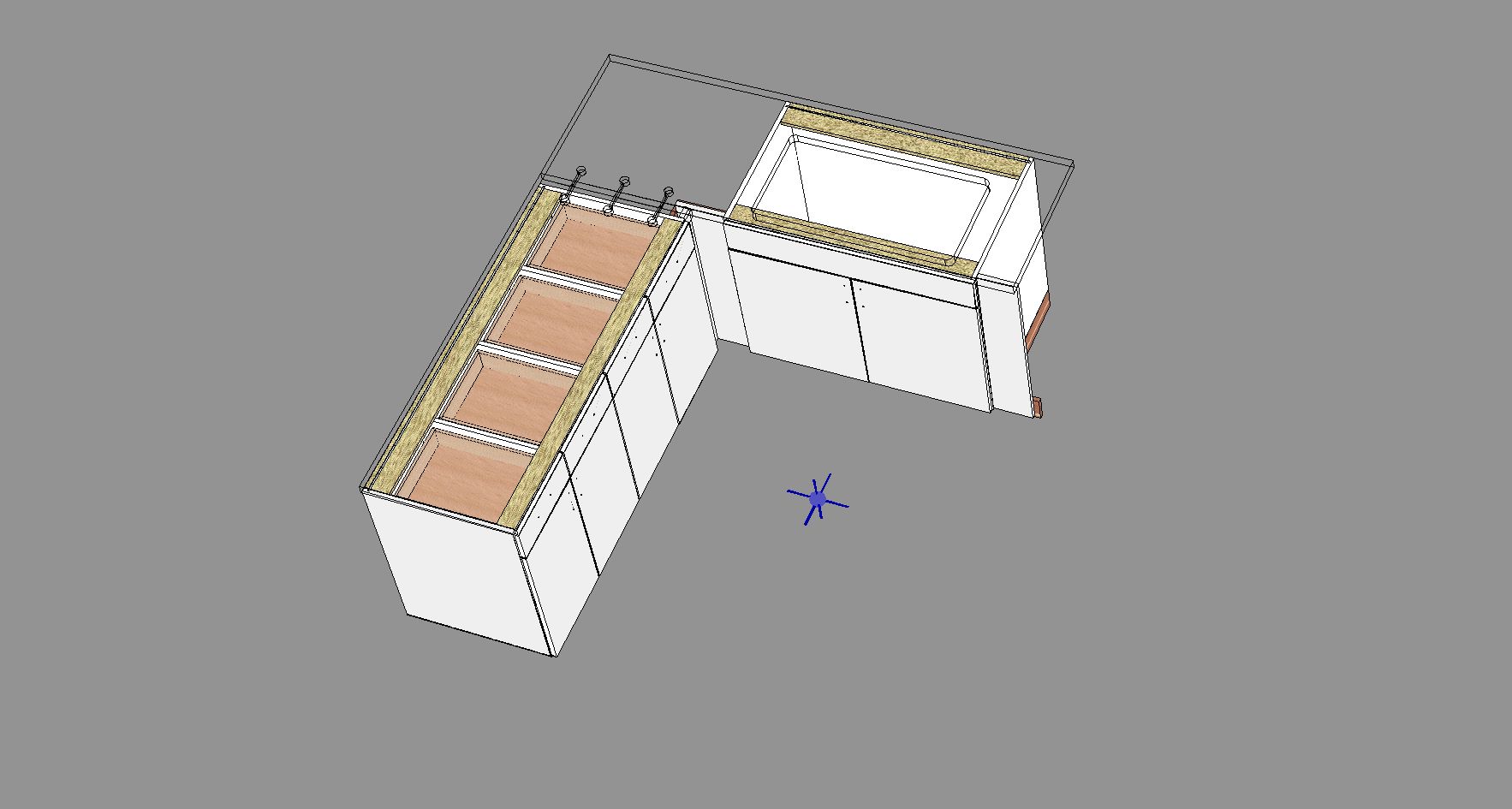

There is a very simple way to make the miters work. You need to make the miter bomb proof. That could be a combination of splines, dominos, and a good adhesives like epoxy. Basically if you assembled you miter and left it on the work bench it would be there forever.

The trick is how you fasten it to your cabinets or table legs. You've got two options. You can either fasten one leg of the L hard to the cabinets, then fasten the other leg loose(3/4" holes with 1 1/4" fender washers) is the most fool proof way. Use a screwdriver to tighten the screws. Leave them a little loose. The counter is effectively sitting there under its own weight.

The other option is to fasten the mitered joint area (2" either side) hard to the cabinets. Then do the fender washer loose install on both of the legs. This reduces the visible movement 50% by sharing it on both legs.

You need to design the with cabinetry such that the minute movement over time is not apparent to the casual observer. Good thing is most countertops have a decent amount of overhang.

Please do not say this will not work, unless you have seen it fail. I've done this on 6 different projects over 30 years with no problems whatsoever. I would do it in my own house.