Message Thread:

Smaller CNC router choices, dedicated for small wood components

12/23/15

We are contemplating adding a smaller CNC router to our arsenal just to keep from having to occupy time on the larger router when the need to make small wood components arises (arched valences up to 36", maybe 48, and cutting small corbels and such).

We do not need anything that is a high capacity, we are more concerned with something that is reliable.

My suspicion is that something as simple as a "shop bot" would work for us, but this is not a niche that I have interacted with at all.

If anyone can help me who understands this particular market and what sort of things I should be looking for in a basic small-nest router, I would be greatly appreciative.

Woods we will be routing are the standard fare-- red oak, hard/soft maple, walnut,cherry, etc.

12/23/15 #2: Smaller CNC router choices, dedicat ...

Website: http://www.joecoholiccustomfurniture.com

Website: http://www.joecoholiccustomfurniture.com

I have a Shopbot Alpha router, with a 4 Hp HSD spindle. I can use tooling up to 3/4" diameter shank. I mainly use 1/2" and 5/8" spiral carbide bits for shaping solid wood, but also do carvings with 1/8 and smaller bits (for instance just ran a carved rocking horse on the face of a large blanket chest, today).

I use mine predominantly for machining solid wood components, in my custom wood business (things like carved chair seats & backs, table bases, curved mouldings, hand rail parts, etc.).

It is a "basic" system (although I also have a universal vacuum table with 10HP pump for cutting plywood or solid material in larger pcs) which I have added an aluminum T track bed, for easy clamping of my jigs and fixtures.

I really like the SHopbot operating system, it is easy to use, and mine has been very reliable for the past 4 years it has been in use in our shop.

They are what they are. Working within the limitations of the machine, you can do some pretty amazing work.

12/24/15 #4: Smaller CNC router choices, dedicat ...

Both Shopbot and CAMaster have Forums for their end users, I own the CAMaster machines in my shop and have my reasons for that, yet there are choices.

Due diligence is crucial I can only encourage you to join those forums ask the questions of the thousands of Owners of each machines, GO VISIT the shops of owners (there is one near you) and go see the machine companies.

Fell free to ask any questions and have some one walk you thru you part production. I have had the CAMasters (Now 6 of them) since 07, could it have been another machine,, yes but in my case the industrial frames and ATC made the difference.

www.camaster.com

Andrew hope to see you this Spring, Dates will be se soon...

http://camheads.org

12/24/15 #5: Smaller CNC router choices, dedicat ...

Do you need an ATC or is one tool enough

12/24/15 #6: Smaller CNC router choices, dedicat ...

Website: http://www.joecoholiccustomfurniture.com

Website: http://www.joecoholiccustomfurniture.com

I posted re Shopbot since that's what I have and use. I know a lot of other guys who use and love their Camaster machines and love them too.

Jim, I certainly hope to be down in SC again is work and family permits! Was crazy busy this past year and 2016 is looking to be similar. But it has been a great trip for me the past few years!

Personally, for solid wood machining (again the stuff I am doing) I dont find ATC a pain to be without. Mainly just swaping from a larger ball end mill to a regular spiral bit. I think if I even get another machine I'd look into ATC, but it will certainly add another $10K plus.

12/24/15 #7: Smaller CNC router choices, dedicat ...

Andrew, I do hope you can make it !!

CAMaster has a new x4 model called panther that is a 4 tool atc that is selling really good, I am driving over to sumter next week to see one as I need a third machine

12/25/15 #8: Smaller CNC router choices, dedicat ...

You might consider talking to CNT Motion. They do a lot of custom use and size machines and could easily build what you need. I suspect the price would be very reasonable for a custom sized machine given that you can live without an ATC.

BH Davis

12/27/15 #9: Smaller CNC router choices, dedicat ...

This is exactly what I was needing to hear.

Having never used, nor seen one in action, I didn't even think about tool changes. Honestly I don't think we need more than the basic cutter, most of what we would cut would just be standard shapes with square cuts.

Our larger router actually is a CNT Motion. I'll investigate and see if they make these lower yield machines.

12/27/15 #10: Smaller CNC router choices, dedicat ...

One second question, and pardon my mediocre/dangerous level of knowledge of CAD and such.

Do any of these pre-fab type routers (Camaster, Shopbot) have.... or come with... software available for drawing various shapes/profiles? It would be nice if I (as production manager) were able to relieve our kitchen designer/engineers of the duty of drawing the simple items.

I know I could probably just put TurboCad on the same PC as the ShopBot/Camaster, I'm just wondering if either of these router companies offered a simpler, quicker software for drawing these standard items. TurboCad is a bit overkill for simple drawing of a few corbels or arches with specific radius sizes, etc.

Thanks!

Matt

12/27/15 #11: Smaller CNC router choices, dedicat ...

Matt,

Years ago Kelly Davis at WinCNC developed wizards for me that allow us to create true radius arched moulding cut out files right at the CNC. It worked (and still works) so well that they added it as a module in the software.

So any machine that runs on WinCNC should have that module available.

BH Davis

12/27/15 #12: Smaller CNC router choices, dedicat ...

Website: http://mcgrewwoodwork.com

Website: http://mcgrewwoodwork.com

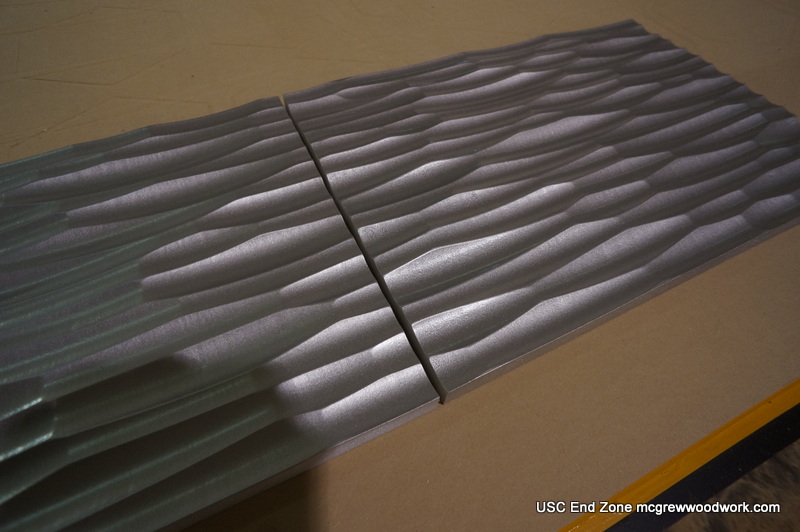

Camaster is wincnc controlled. feel free to ask about what you want to achieve, go visit shops, we hold a really big CNC event in my shop in April that draws camheads, botters and a host of talented fellows in this stuff when it comes to custom

just what do you want to do and the chess players were done with a single head machine with a 6" z clearance

View higher quality, full size image (1023 X 682)

View higher quality, full size image (800 X 534)

View higher quality, full size image (800 X 532)

12/27/15 #13: Smaller CNC router choices, dedicat ...

Both companys provide Vectrics VCP, I use vectrics aspire if you want to come in April speak up.

these programs will never meet all the metrics of a good cad program for some features but I have found nothing I have been unable to do with it.. go to vectric.com and download the programs for testing, you can make and see files run it is the full version, you can save but not produce code until you purchase and that is not until you are satisfied.

Take a look at their forum as well you can link from the website

12/28/15 #14: Smaller CNC router choices, dedicat ...

BH Davis--- that sounds enticing, we already run WinCNC on our current router. I will look into that very shortly. Thanks for that information.

James McGrew, we are about 80 miles from you. I may very well be at this conference. Thank you for this, that's exciting.

Incredible work by the way. I can see how most of those items were done on a CNC but those giant chess players are a whole new level. Fantastic results!

12/28/15 #15: Smaller CNC router choices, dedicat ...

Feel free to visit if you want just let me know. were in SC are ya !

6/6/21 #16: Smaller CNC router choices, dedicat ...

Website: https://forsuncnc.com/

Website: https://forsuncnc.com/

I recommend that you use an ATC CNC router machine. The automatic tool-changing router machine has two types: disc and inline type. The use of an 8—12-tool rotating conveyor belt can speed up tool changes, thereby ensuring faster cycle times, thereby increasing throughput.

View larger image

|