Message Thread:

Researching 5x10 Nested CNC's Biesse,Holzher,Anderson

3/31/20

Website: https://www.instagram.com/innovativebuildingservic...

Website: https://www.instagram.com/innovativebuildingservic...

Im In the process of doing research on 5x10 nested machines for my small 2 man shop, 7 man company, we are a contracting, carpentry, woodworking, custom builder. we do everything from Custom kitchen cabinets , vanities , closets , built ins , to historic trims and moldings for historic renovations.

My research has taken me to Newcnc talent t3, Homag n-300, Giben g2/g4, Anderson spectrum/selexx plus, Holzher dynestic 7505 , Biesse rover k ft

Im Looking for the machine only no room for on and off load at this moment but will want to add that capability in the future as we expand. My list above is in order of pricing ranging from $67k-$100k.

Software - im Familiar with is mosaik and vcarve pro

Wishlist - Fast , reliable , 12+ tool change, Drill Head, excellent dust collection, ability to work on random small parts, vacuum pods , laser positioning, saw head to cut mitered joints

Your guys Opinions on the above machines would be awesome. i would love to go out and demo machines and talk to owners but with everything going on with this virus that is not possible currently.

Thanks

Rich

3/31/20 #2: Researching 5x10 Nested CNC's Biess ...

I would base my decision on which of those companies has the most responsive phone support, service techs, and parts available to your area. Some of those CNCs won't meet all of your wishlist items for under $100k so prepare to compromise or up your budget. As I recall, only the Biesse has a saw option. Also, many CNCs cannot have loading and unloading added after installation, as the provisioning for those features is added at the factory. I went with Stiles about 4 years ago, as they have a strong presence where I'm at, and have been very satisfied with their support. I picked up a Weeke Vantech, which is the predecessor to the N-300 you're considering. Their phone support has been tops, even out of warranty, and tech visits, while pricey, have resolved every issue quickly. At one point my machine was misbehaving and the phone tech walked me through some very thorough troubleshooting and correctly diagnosed it to a faulty breaker outside my building. Never saw a bad breaker before, and his time didn't cost me a dime. Not everyone loves Stiles, but my experience has been great.

3/31/20 #3: Researching 5x10 Nested CNC's Biess ...

Appreciate that yea Still feeling out the sales guys / reps asking a bunch of questions trying to see whos the most responsive and willing to answer all my questions.

3/31/20 #4: Researching 5x10 Nested CNC's Biess ...

i guess a v grove miter router bit would also allow me to make mitered corners for speaker boxes

3/31/20 #6: Researching 5x10 Nested CNC's Biess ...

Website: nutekmachinery.com

Website: nutekmachinery.com

Rich,

I've been a technician for over 30 years and have worked on all of the brands you mentioned. I also am in sales with lines I direct import through NuTek as well as selling the Giben line. Giben is owned and made by Anderson Industrial. The software on Giben is the most user friendly I have seen on any machine with everything accessible from one page. Standard is a 5 x 5 drill block but you can get 10 x 7 if you wish. The drill block typically eliminates the need for a 12 position tool changer but that is available as well. In regards to support I often take calls in the evening from customers of mine if it's after hours for Giben. Don't underestimate the importance of integrating your machine into your production. I've seen more then one machine sit for 6 months or more due to the lack of understanding of how to properly utilize the machine. Feel free to go to my website and call or email me if you want to talk more in depth.

3/31/20 #7: Researching 5x10 Nested CNC's Biess ...

some of the units G4/selexx have the tool carousel ride along the gantry with the spindle to me that seems like it would provide the quickest tool changes? is that fair? i know it depends on the machine as a whole. but seems like the most advanced option. i see homag offers it as an option on the n-300

3/31/20 #8: Researching 5x10 Nested CNC's Biess ...

Website: nutekmachinery.com

Website: nutekmachinery.com

Rich,

A tool carousel that travels with the machine is much faster. With a stationary tool changer you will need to always travel to the stationary rack and after depositing a tool travel in the short axis to pick up the next tool. Dependent on your location I can do a online demo for you if you would like or set you up with the appropriate person to do one for you.

3/31/20 #9: Researching 5x10 Nested CNC's Biess ...

My take on ride-along tool carousels: tool changes can't occur until the spindle brakes to 0 RPM, and that takes a few seconds. In that time, most machines can make the traverse to wherever their tools are stored, either in a stationary carousel or tool rack at the end of the table. It used to be a selling point but realistically it is a gain of a few seconds per sheet, not statistically significant.

3/31/20 #10: Researching 5x10 Nested CNC's Biess ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

I agree with Jared on the carousel. I don't know if you gain much, and will include that you are adding another moving thing that can potentially fail.

Stiles is a blessing and a curse. When I've needed them, they have been Johnny on the spot with either techs or phone support. To me, that's worth paying a bit more for other things. Like super special Deutschland grease.

4/1/20 #11: Researching 5x10 Nested CNC's Biess ...

That is a pretty light budget for all of your wishes. I think in that price range, ultimately you will be disappointed unless you don't have CNC experience. Have you looked at used machines? You can get a lot of bang for the $ if you have some experience.

4/2/20 #12: Researching 5x10 Nested CNC's Biess ...

We have a Biesse Klever , its there smaller 5x10 machine. Great machine , Biesse service has been fantastic with this one and our previous cnc we bought used.

Our machine has the rack instead of a carousel, the old one had a carousel. I really don't see a time difference for our use.

We have a Brandt/Homag bander. Stiles has been fantastic with support on that.

4/2/20 #13: Researching 5x10 Nested CNC's Biess ...

anderson selexx and holzher 7505 come with ballscrews on the y axis you have to upgrade machines to get that feature with others. they say this will help with precision work for hardwood milling and mdf doors. what say you?

4/2/20 #14: Researching 5x10 Nested CNC's Biess ...

FWIW I bought a used Anderson stratos this year at auction. Assembling the gantry after moving I dropped it off my forklift and bent the linear guide rail.

It was a stock part from Bosch/Rexroth and I had it in my shop in two weeks for 325.00 and I placed the order and replaced the part myself no tech needed.

Then I found a great tech in another state and we did everything over the internet, training, adjusting, working through setting it up after moving it three states.

I got my posts up and running with the tech as well and am now cutting parts with it.

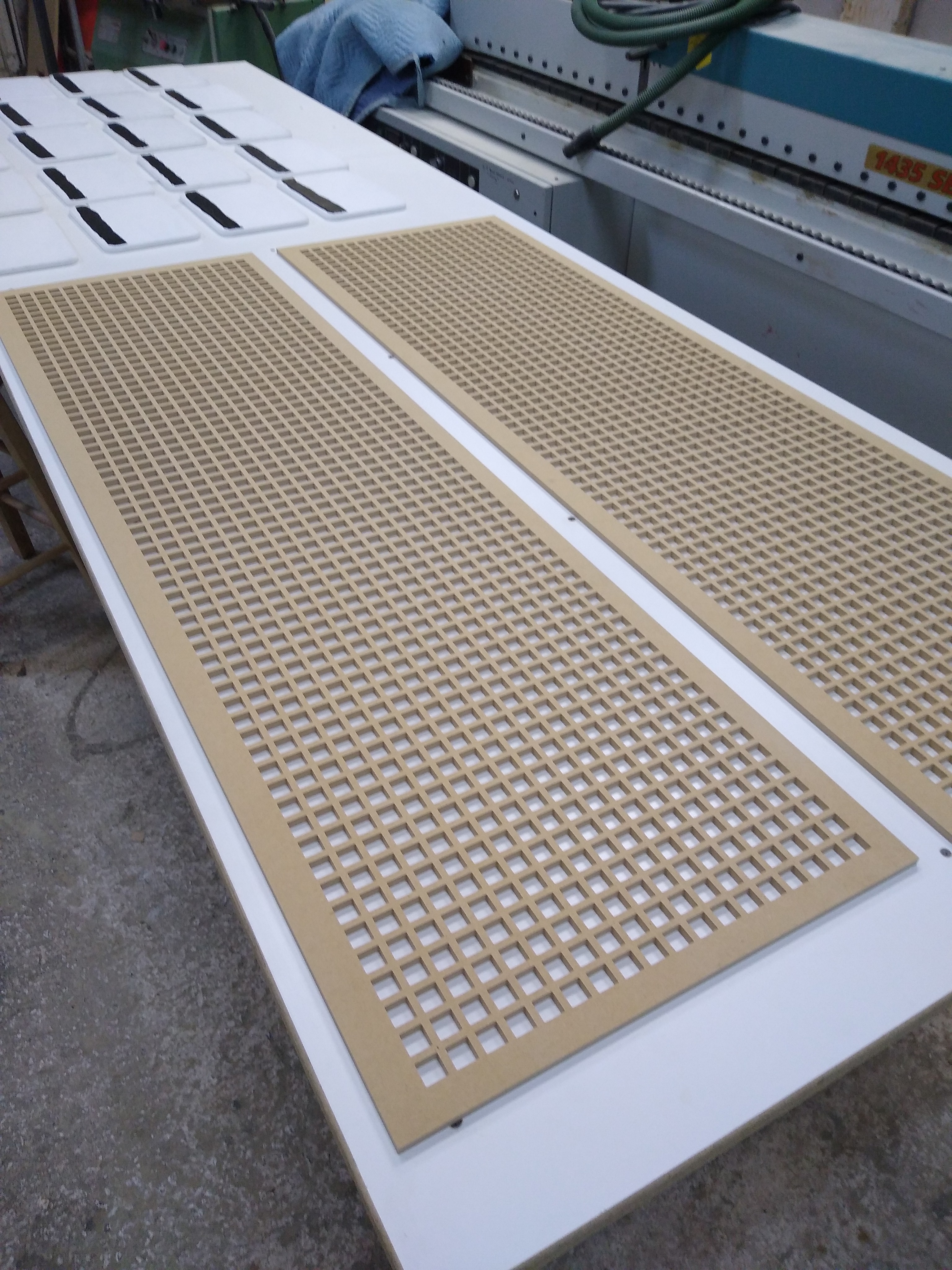

What the above poster stated is true the ball screws have been proven to be extremely accurate. The first three parts I cut had 1600 3/4 x 3/4 holes in them with a 1/4 space between them and I ramped in with a 1/16" bit for the final pass to clean the inside corners and the finish was flawless and perfectly consistent from one end to the other, no tool marks whatsoever.

This from a machine that I moved and set up myself from three states away and dropped the gantry , replaced a guide rail on etc.... needless to say I was super impressed and all for less than the cost of a new shop bot. It only cuts at 900 ipm because of the ball screws but I am a one man shop so I have not found that to be an issue.

Also it is a straight G code machine so no issues trying to deal with some euro work around on the machine control.

View higher quality, full size image (3072 X 4096)

View higher quality, full size image (3072 X 4096)

View higher quality, full size image (3072 X 4096)

4/4/20 #15: Researching 5x10 Nested CNC's Biess ...

Biesse support is the best there is. 15 years and 2 cnc with them. Great thing is you donít need it very often because machines just run!

4/5/20 #16: Researching 5x10 Nested CNC's Biess ...

Quicktrim that is a nice machine all ballscrew. thats kind of where im at now since i will be doing alot of hardwood milling. Kind of narrowing it down waiting to get more info on the stratos nest , im assuming / wondering if the biesse units being Italian rack and pinion are just as accurate.

Im in maryland so felder is only 45min from me.

There format4 lineup looks very interesting h10 h80 h100 h150

Also looking into 5 axis units now if im going to spend 10-20k on aggregates.. to saw cut miters and cut hinge and knob pockets why not just go full 5 axis

4/6/20 #18: Researching 5x10 Nested CNC's Biess ...

Thats why I thought your budget was light if you wanted to mitre fold with a saw. If you look on the used side, you may be able to find a nice machine with a dedicated saw unit. I have one on mine, plus a handful of aggregates. The saw gives a far superior cut on solid wood, corian, laminate, you name it. The aggregates are doing the cutting to far away from the power input to really be rigid enough for me. Just my 2 cents. Salesmen always oversell aggregate potential. I use 3 of them all the time, but you have to treat them gently if you want them to last.

4/6/20 #19: Researching 5x10 Nested CNC's Biess ...

I have nothing but good things to say about our biesse machine, as well as their support. Every machine will have quirks/issues, but their support/techs have been invaluable. They always have gotten back to me on the same day, and never have I been left with a problem unsolved, or a question unanswered.

4/6/20 #20: Researching 5x10 Nested CNC's Biess ...

FWIW I would love to have a saw on my machine as I miter fold a lot of solid surface on mine. I had a custom integrated head made by vortex with 90.5 degree inserts and a short body from the hsk 63 so it works well, but I would ideally like to have a tiltable saw as this would speed up cut out and make the miter cutting better.

My next machine will have that I hope.....but that's a ways off, if you can swing it get the saw head now, I do wish I had one.

4/7/20 #21: Researching 5x10 Nested CNC's Biess ...

Quick Trim

Do you mean a C axis or an aggregate or something else?

4/7/20 #22: Researching 5x10 Nested CNC's Biess ...

On this subject I see a few Onsrud routers comes up at auction, they don't have the moving table problem of a Komo, is there any thing wrong with these machines if they have a better controller than an AMC, I think some of them have Fanucs?

4/7/20 #23: Researching 5x10 Nested CNC's Biess ...

Pat,

I read somewhere that Onsrud wasn't supporting the older obsolete controllers. Not sure which one though, probably the AMC I would image Fanuc would always support there equipment .

I have heard horror stories about Felder support, especially on the 5 axis

4/7/20 #24: Researching 5x10 Nested CNC's Biess ...

Thanks Bob

That is a good point, which probably has a lot to do with the price at auction.

4/7/20 #25: Researching 5x10 Nested CNC's Biess ...

Pat,

I mean a dedicated saw on a swivel head. A C axis would be nice but it seems like a lot of the aggregates get in the way a bit and the saw blades are never very big. However a c axis aggregate with a shaper type head that has a 90 degree cutter would probably do nicely. The Onsruds are very nice and if they have the Fanuc control I would go for one, I bid on several before I got my Anderson. They were right up there in my opinion. There is a nice KOMO in texas that will auction in a coulple days if you have the space for that table style. I would guess it will go for about 3500.00 - 5500.00

4/8/20 #26: Researching 5x10 Nested CNC's Biess ...

The Komo seem plentiful at auction, I don't like that they take 300 sq ft, I like the company and the people seem terrific and the Fanuc controller are big pluses.

The Onsrud would not take up as much room Onsrud seems like a good company I have used machines that had the AMC controller they seemed fine but if they are no long being supported that is a show stopper.

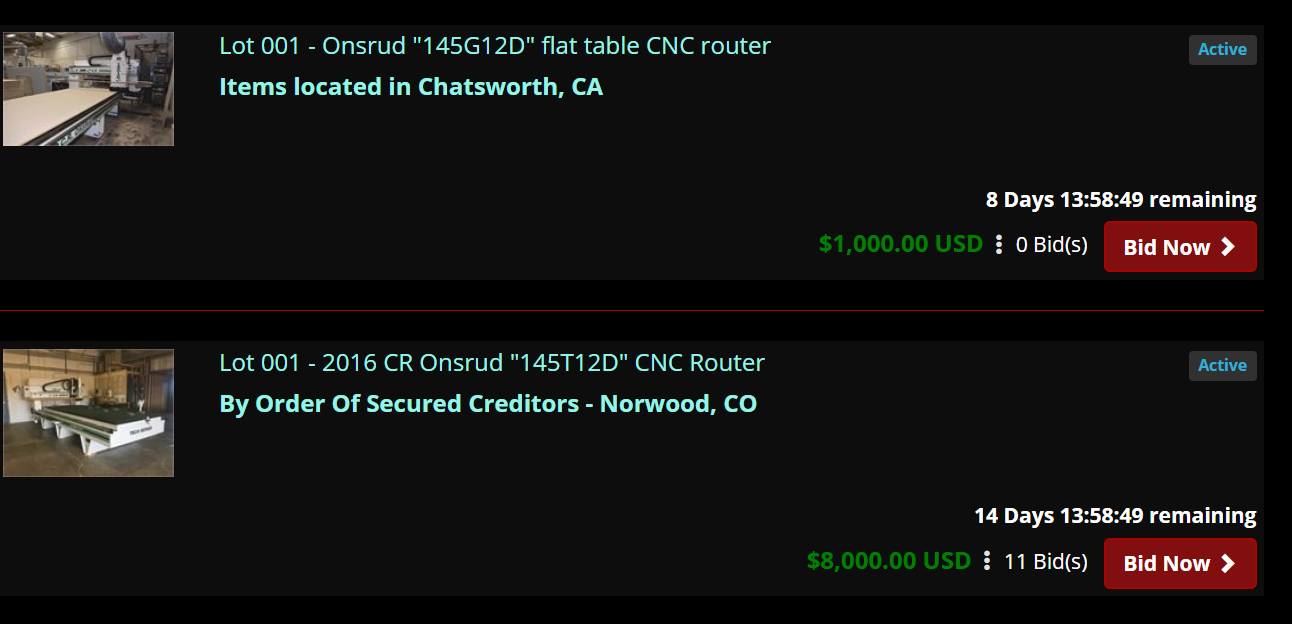

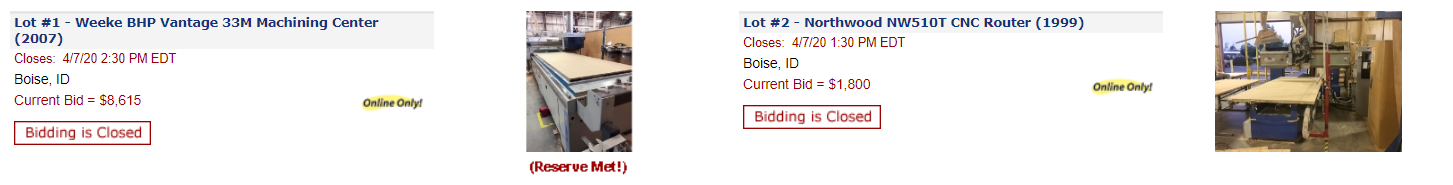

This picture shows a 2004 at the top of the picture and a 2016 at the bottom notice 0 bids for the top one and 8 for the bottom one with 14 days to go

View higher quality, full size image (1292 X 624)

4/8/20 #27: Researching 5x10 Nested CNC's Biess ...

what are some of the best places to watch auctions i think im leaning toward that route ive seem some 1-2 year old 100+k machines go for 30k

4/8/20 #28: Researching 5x10 Nested CNC's Biess ...

If you are ok with buying a used machine there should be an abundance of used ones available later this year as the fallout from this shutdown is going to be a lot worse than 2008. There were tons of machines selling back then for pennies on the dollar.

It is sad but true.

4/8/20 #29: Researching 5x10 Nested CNC's Biess ...

Pat,

That Onsrud machine in CO is a nice one, the Vac pump alone that comes with it is worth 5 - 8 k easy.

IRS Auctions Industrial Recovery Service

and Machinery max are two of the best auction services to check out.

I am betting there will be a lot of deals out there in the next 6 - 12 months.

Kind of wish I would have waited a little longer, but I needed to cut parts by now anyways.

Just remember it will take at least another 10 K above purchase price to get it to your shop and set it up, even if you have all the air, power, and dust collection you need already.

Then another 3 - 4 k in tooling etc..

Software....

Training.....

4/9/20 #30: Researching 5x10 Nested CNC's Biess ...

Am I thinking right that a Komo would take 300 sq ft?

Click the link below to download the file included with this post.

Komo_Machine_Xtreme_XL510_Layout__1_.pdf

4/9/20 #31: Researching 5x10 Nested CNC's Biess ...

Not to mention the 15% fee to auctioneer, that didn't exist not too long ago. I guess the money would have come out of the seller before.

Is Sales tax enforced on out of state sales?

Those two items would add 23% or so as well

4/9/20 #32: Researching 5x10 Nested CNC's Biess ...

I paid the auction fee but they did not charge me sales tax, I bought out of state.

I am not sure about the 300 square feet but it seems about right

4/10/20 #33: Researching 5x10 Nested CNC's Biess ...

Quick Trim

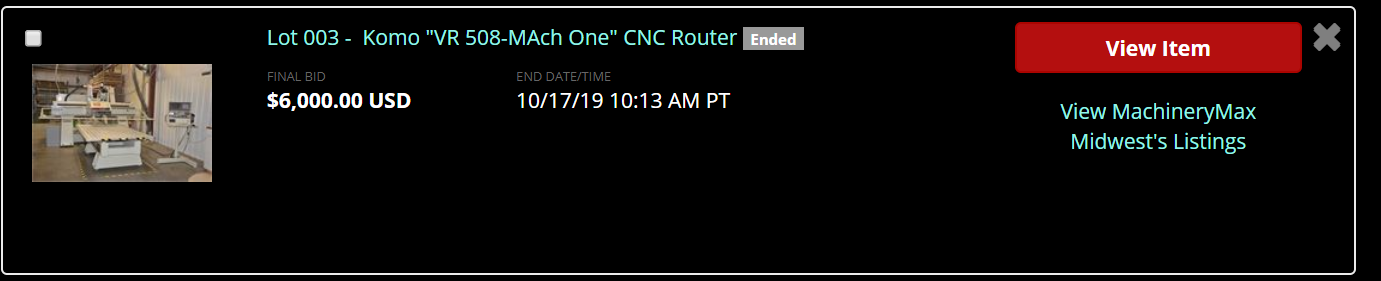

You came close on your prediction

View higher quality, full size image (1381 X 281)

4/11/20 #34: Researching 5x10 Nested CNC's Biess ...

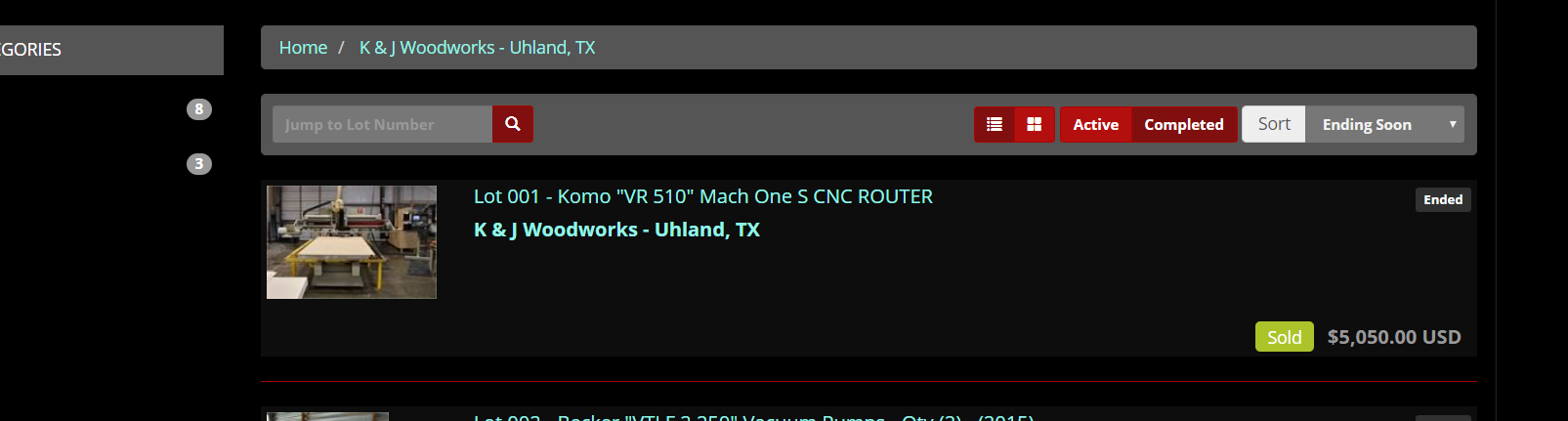

Actually I was right on , this is the one I was talking about, ended yesterday in texas. I am actually surprised it didin't stop at 4 ish but you never know and this one was a 2003 and in good shape. I am a little surprised that it went for that with the covid and that Onsrud in Colorado will be real interesting to see what it goes for, I bid on on just like it last year and it went for over 100 K and this one is only one year older so we will get to see how people are feeling about the economy with that one if it goes for under 30 ill be surprised and if it goes for over 55 I would say were not in for much of a hit on the economy.

View higher quality, full size image (1605 X 431)

4/11/20 #35: Researching 5x10 Nested CNC's Biess ...

Check this out, sold this week 2007 Weeke with offloading and two 2014 becker vac pumps and an older northwood for under 2k there are some good deals out there to start CNC on a budget for sure.

View higher quality, full size image (767 X 183)

View higher quality, full size image (1453 X 185)

4/11/20 #36: Researching 5x10 Nested CNC's Biess ...

Not sure of the value of the Dodds if you have to dovetail drawers it seems like cnc would be the way to go.

The Northwood could kill you on parts

Not sure about how long a Weeke, 10 years?

That is my take on it, but I could be wrong

|