Message Thread:

CNC worth the investment? What's the best option?

6/19/20

I own a small 3 owner/operator cabinet shop for the past 9 years building mid to high end custom cabinets. Our company consists of my husband, myself and brother in law. We average about 1 mid to high end custom home (12,000 sqft home~80 cabinets) every month and a half. We build face frame cabinetry and our biggest hang up is the time it takes cutting out cabinet parts, dadoing, drilling and notching for toe. I can cut, build, joint and sand face frames before both of them have boxes ready. We have a large panel saw, table saw, dedicated table saw with dado and adj shelf drill boring machine. I'd like to simplify the process and get a CNC but completely clueless on what options there are as far as CNC machines and what software is best. When we started we used microvellum with the design only version. We have our own excel cutlist sheet so the software has only been for client and shop drawings. I've dabbled with KCD 2 yrs ago on a free trial and currently use Chief Architect because of the rendering abilities, 360 views and 3D walkthroughs for clients. I spend a lot of time doing a manual cutlist and obviously a lot of time is spent on manual cutout of cabinet parts but I don't want to have to take out a mortgage on a CNC and software. Is there such thing as a decent CNC and software for 40-60K (or less?) or is that laughable? The boys think that if a CNC isn't running every day it isn't making money it's costing money. How do I get them to understand that this will save money and time in the long run or am I crazy one?

6/19/20 #2: CNC worth the investment? What's th ...

There are several CNC that would work for you that is well within your price range. most of the box parts are standard so you only have to have a few files for them. What you can do is throw a sheet on and let it run while doing other things like assembling the cabinets. You don't need to run the CNC all the time just like you don't run the rest of your tools constantly. also you may be able to pick up other work for it.

6/19/20 #3: CNC worth the investment? What's th ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

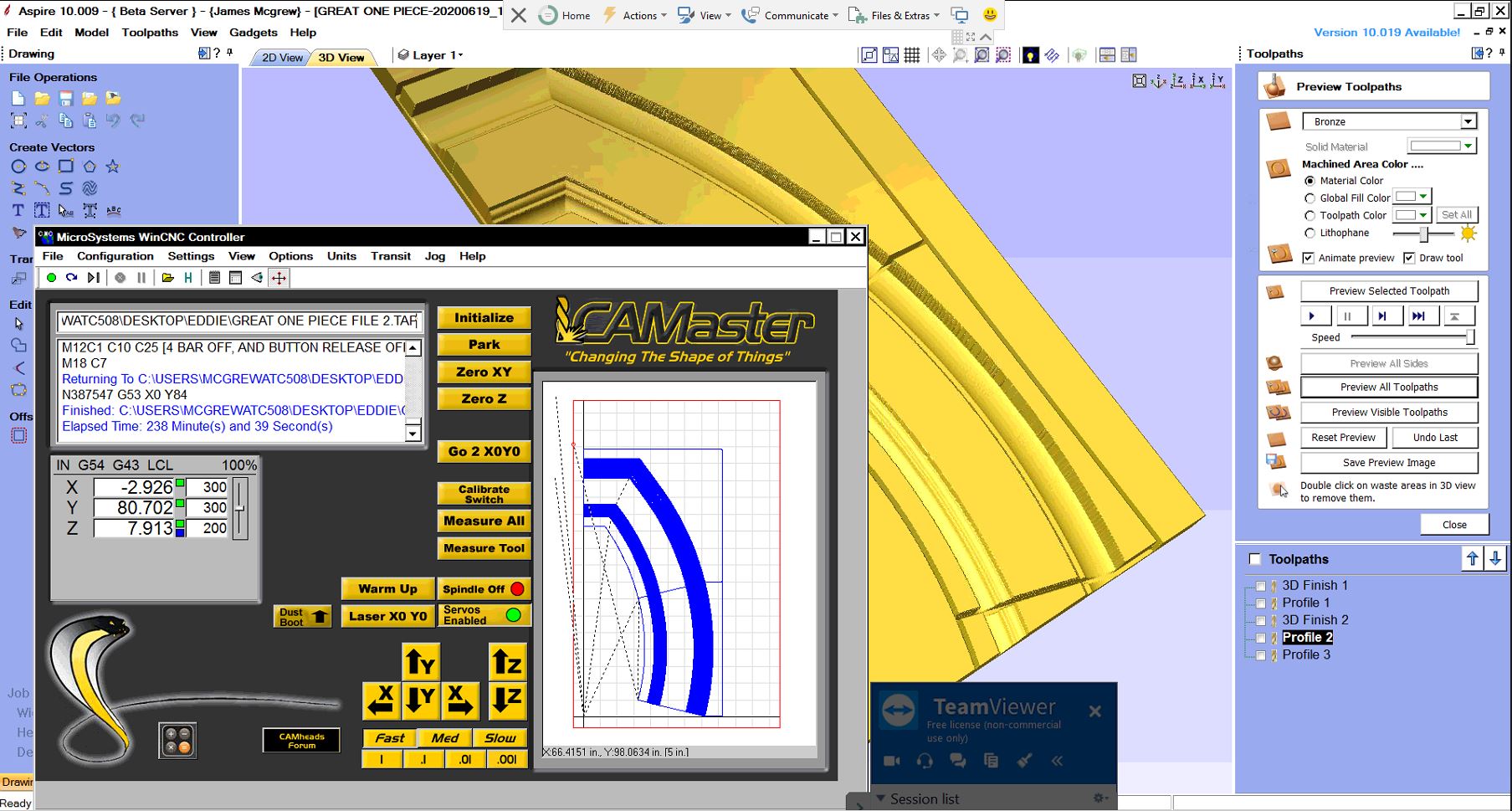

There is little to think "Laughable" about a mid size CNC with a ATC. mine is a 2012 Camaster with 25hp vacuum and dedicated dust collector. at this point our volume is higher thasn the one you listed and we pretty much were at the point you are in 2007.

we have used most all softwares (except) MV since 1997. When I buy a tool I learnedto by My 2nd need first and this meant i had bought the tool to last for a decade +

With your volume you will have cut Box parts machined and ready to assemble in 3-5 hours

View higher quality, full size image (1600 X 1064)

View higher quality, full size image (1600 X 1064)

6/19/20 #4: CNC worth the investment? What's th ...

Get a 4x8 sheet nester (go with a 5x12 table if there is anyway you can) and throw the whole sheet on there. The Thermwood machines come with free software (eCabS) that will get you started fast, just as an example. You can move to another software with fuller features if you grow into the need. Unless you get a junk machine, any money you spend on a CNC machine will be worth every penny, if you actually use it. if you run it 50% of the time, then it just takes twice as long to pay off the loan, that's all. The efficiency it adds to processing is pretty much a no-brainer. Don't be afraid to jump in, but be as educated as you can about your first machine. It will flatten the learning curve quite a bit if you are not working around limitations of the machine. You will certainly want ATC and 6 tool holders or so, to make the necessary cabinet operations. VISIT a shop somewhere that is running the machine you plan to purchase to SEE the workflow and software in use. IMHO.

6/19/20 #5: CNC worth the investment? What's th ...

Just a different way to look at this. Have you considered outsourcing your cabinet boxes - allowing you to focus on selling, finishing and installs?

Cabinotch

6/19/20 #7: CNC worth the investment? What's th ...

Thank you all for your help and advice. Yes we have a local company who we could farm out box parts to. We already have another local company/friend who builds drawer boxes and doors/drawers for us. He recently got a CNC which is part of the reason why I'm curious about getting one ourselves but he's a larger operation with just over 30 employees and builds frameless cabinets. I'm not sure what CNC he has but I know he uses Cabinet Vision and paid over 60k and flew one of his employees out to get training with their CNC. We decided early on to have another company do doors and dovetail drawer boxes for us to allow us to fit more jobs in a year. This allowed for more door styles for clients as well. Only issue is it ends up being about 10% of the cost of any job. My husband isn't interested in farming out even more of our stuff to someone else with a CNC. My thoughts are then lets do it in house and be that much more efficient in getting jobs out faster. You have a good point not every tool we own is used every hour of every day. With everyone getting taller ceilings we'd want a larger table to fit 10' sheets for sure. What brands would you say would be great "beginner" CNCs that you could tool up or add to later down the road as your finances or needs required? (is that even a possible thing?) Total newbie here sorry! Is there a resource that would be helpful to learn more about different options other than local companies and salesmen? There's a shopbot for sale locally but just don't know if that's a good brand for cabinetry industrial work or more like really enthusiastic woodworking hobbyist if that makes sense? lol

6/19/20 #8: CNC worth the investment? What's th ...

For 80 boxes your machine would run about 14-16 hours a month. This would give you the ability to sell more or produce more work in the same amount of time or bring some items back in house or go fishing more.

What is your cutting time for 80 boxes?

Then there is the huge advantage for any irregular shape, radius-ed or odd shaped parts that can be machined from the drawing.

We bought our first CNC in 95, we started looking in 88 and got serious in 94.

That first step up to CNC is a big decision cost and impact wise but there are just so many benefits beyond production increases.

You may need more power and clean air.

A-

6/19/20 #9: CNC worth the investment? What's th ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

Shop Bot has a forum for its owners as well as CAMaster

Feel free to Join CAMheads it has a few 10 of thoudands on;ine like yourself,, While it is a CAMaster forum it is moderated by Owners not salesmen ot techs.

remember to use the activation email you will get so you can see photos and post

Camheads

6/19/20 #10: CNC worth the investment? What's th ...

FWIW

I bought an Anderson Stratos 5x10 for 30,000.00 at auction. It will cost some to get software and other things for it. But if you educate yourself you can save a ton and all your boxes will be perfect. You will save so much time you can bring other ops in house and capture that money too.

I cut all my dovetail drawer boxes on it also so I only outsource doors now.

It will take a lot of effort and time to get there but if you donít I am afraid you will be a dinosaur.

6/20/20 #11: CNC worth the investment? What's th ...

Website: http://www.kdunphy.com

Website: http://www.kdunphy.com

I'm a small shop there are cnc for almost every budget l can speak for shopbot great machine .James love to prompt his cnc have to agree great machine .

What the cnc machines does you realize the cabinet are just boxes simple .

I don't think my shop would be open without a cnc

6/20/20 #12: CNC worth the investment? What's th ...

Check these guys out, they have a combination router / drill block available for their machines. You could run sheet nesting operations and drill in one process. With a saw aggregate you can keep your end mill tooling cost down also. When you get comfortable with the machine, you can work on 3d modeling or even buy .STL files for accent architecture- corbels and such.My only advice is to get more Z than you think you will need. Make a list of all the possibilities that you may manufacture. Take into account fixturing height and initial size of the component. Aggregate tooling opens up many possibilities.Don't forget that a cnc is an employee who doesn't need lunch breaks . We gain time running it through lunches and breaks.Also once the program is proven, you can be doing other things. Now you are effectively two people.

RouterCad

6/20/20 #13: CNC worth the investment? What's th ...

Jennifer,

What you are asking has been asked over and over. Not a problem, the answer is usually the same. I wish we would have bought one sooner, and I wish I would have spent more. All of us who own a cnc have made these statements. A cnc can and will increase your out put. It will cut, drill, optimize and make your dado's faster than all three of you can. It will open the doors for other opportunities. All of this is possible even if you are using inexpensive software like sketchup and vcarve. (not looking for an argument guys just stating the facts)

It sounds like the three of you are working to your limit now. A good cnc can be had for less than $1000.00 a month. Less than you will pay for another employee in salary, workmans comp, taxes and ect. Bite the bullet....you will say, " I wish we had done this earlier and I wish we would have spent more money."

6/20/20 #14: CNC worth the investment? What's th ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

"Other Opportunitys" Plenty of that with a little application and yes with Vectric Vcarve and Aspire (other than Moziak)

I I ran this file 30 miles away from the cnc while working at my Farm. Just had a fellow go and clean up while the CNC ran

This is a mould cut as a negative in PVC A self build Homeowner is making his own Concrete Columns and arches for the entrances to his home

This is the main door arch over and I will show more later

If you are seeing this message, your version of flash needs to be upgraded to view this video.

Click here to get the latest version of the Flash player. |

View higher quality, full size image (1293 X 666)

View higher quality, full size image (1807 X 969)

6/23/20 #15: CNC worth the investment? What's th ...

Buy your second machine first even if it is more than you want to spend. With your volume it won't run a lot. This is a good thing. If it takes the cnc 10 hours to do what would have taken 25 hours to do then you just saved 15 hours plus spent that amount of time doing something else that is making you money. It opens a lot of doors that you could not have done before. Once you get one and learn how to use it with dados, shelves holes, holes for runners and hinges, ext. you will wonder how you did without it. The more you learn the more things you can offer. We make a lot of custom glass mullion mdf doors and all kinds of arches. I cut out 4 mdf glass doors last week with a couples hours on the computer and a 3 hour cnc time and sold for $1,600. Made the monthly cnc payment and covered my time all in a few hours.

6/28/20 #16: CNC worth the investment? What's th ...

Website: https://www.pintuu.com/

Website: https://www.pintuu.com/

Hi! As a global supply chain management provider, our suggestion is to rent a CNC machine since you only need to use it some times not always taking cost into consideraton. In addition, you could source CNC service outside.

7/6/20 #17: CNC worth the investment? What's th ...

I am not sure where you are located, but without trying to be a downer as we already have enough doom and gloom in the world. I think the recession coming in a lot of areas will be a lot worse than 2008.

I would try find someone who can educate you on CNCís as for what to look for to meet your requirements, including software and tooling.

I would then start looking for a used machine, I could be totally out to lunch, but that is the norm for me. You should be able to pick up machines 20-40 cents on the dollar.

8/25/20 #19: CNC worth the investment? What's th ...

Website: http://forsuncnc.com/

Website: http://forsuncnc.com/

Over the past few years, CNC router machines have been an absolute necessity in the manufacturing sector. They successfully replaced manual machines across various industrial sectors. CNC routers help manufacturers save labor and improve work efficiency, so they have been the most popular machines all over the world, and widely used to cut and carve wood, metal, plastic, stone, foam, and so on.

As you can see, CNC Router has a broad market and development prospects, as long as you develop appropriate strategies and make full use of existing resources, you will definitely be able to read a lot.

If you want to know more about this, I suggest you check this link portable: How to Make Money with CNC Routers?. Hope it can help you learn more about CNC machine tools.

http://forsuncnc.com/make-money-with-cnc-routers/

2/22/22 #20: CNC worth the investment? What's th ...

You can move to another software with fuller features if you grow into the need. Unless you get a junk machine, any money you spend on a CNC machine will be worth every penny, if you actually use it.

|