Message Thread:

new to me cnc

2/4/21

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Well I did a thing... Ive been wanting to go cnc for a long time now, but it has always been out of reach financially, and in my thinking outside of my capabilities. My other excusewas that my shop is extremely low production, just 1 1/2 guys, 8-12 jobs per year...

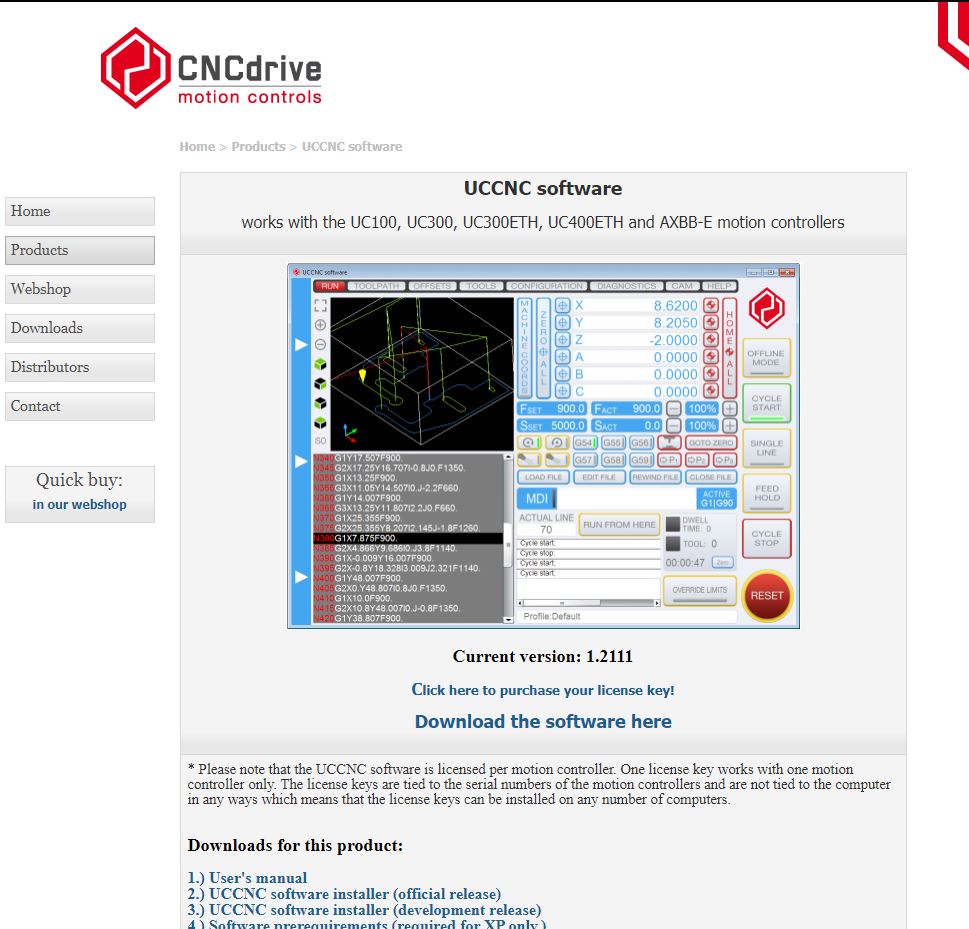

Between reading here and joining the cnczone forum 5 years ago I mustered up the guts to take a risk on an older, very basic, cnc router that I found for what seems to be a swinging deal ($4600 after tax) I have attached pictures. It is a year 2000 machine with very low use. It has HIWIN guides and THK ball screws on all axis, and weighs almost a ton. THe controller is a now obsolete Ah-Ha unit that is still working well. I have hooked it up to a new computer and am now running it on a program called UCCNC, which is like Mach 3 from what ive read. As of now I have only come as far as jogging the machine, and the z axix looks as if Im going to have to replace the stepper motor, but so far Im kinda happy with my beginners purchase.

View higher quality, full size image (640 X 480)

View higher quality, full size image (640 X 480)

View higher quality, full size image (640 X 480)

2/4/21 #2: new to me cnc ...

Congrats. Id imagine you'll soon be looking into replacing that router motor with a spindle. For the size of the machine I suppose the price isnt to bad other than persevering through auctions. You may think about connection with someone like Gary Campbell at GCnc as you upgrade.

Welcome to the whirlpool

2/4/21 #3: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Thanks Mark. It was an ebay auction and I took a leap of faith and bought it only having seen pics and talking with the guy selling it. Yeah the router will go for a tool changer eventually, and probably faster motors ect.. at that time. I think for now Im focused on getting all of the axis settings correct(totally learning), and that dang Z axis issue solved. after that I will be beating the dead horse of how to set up a single phase vacuum table that works... Right now we have quite a bit of work, so Im only able to work on it an hour or two at a time at the end of the day.

2/5/21 #4: new to me cnc ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

My first machine was a 1998 "Bill Hog" WH much the same as you have there. I had mine upgraded to the current controller version , new computer and motors Belts checked etc. made enough money to sell it to a sign shop (it is still running) in Florida.

I then purchased my first new machine with ans ATC. the reason i tell you this is it is cost and value prohibitive to convert this machine to an ATC, can it be done :Yes" should it be? Well only if passion or money outweigh common sense.

Strong machine with cut cabinets and i do miss it sometimes !

2/5/21 #5: new to me cnc ...

Im not a machine builder but I would echo what James mention's. Ive watched several machine builds from scratch a few including ATC and the hard part will be spindle, rack, making it all work, vac table, in combination with what you've already got in the machine, and you will be well into the price range you could snatch up a probably like-new used machine from someone who is upgrading that is fully turn-key.

Its easy to lose track and in short order be in for the cost of a far more robust machine while having a frankenmonster. But you'll surely learn a lot along the way.

2/5/21 #6: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Thanks Jim and Mark! Ji, ive actually been reading your posts for a long time and its partly the inspiration for me buying this machine. Funny you should mention WH machines as I have actually been looking for one, as their power requirements are low. My shop only has single phase power up to 50 amps, so the heavier iron just wont work in my current situation. When I say tool changer, im not talking an HSD with a 10 position rack. more along the lines of this

http://www.midwestrapidtool.com/AutomaticToolChanger.htm or an air drill...

and Im all ears on ideas for a vac table

2/5/21 #7: new to me cnc ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

The man who built these is still around, I can get you his number he is still in GA messing with machines

What is the surface of the machine now. some of these were built a sign machines and the gantry runs completly across under machine. you would have to drill holes thru frame to pipe a vacuum seriously crank it up use it then look at what you have . can you em me a phot of the controller screen ?

View higher quality, full size image (480 X 320)

2/5/21 #8: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Jim you are correct there are two cross bars running across the underside. this machine was originally cutting polymer shelving for high temp electronics ovens. Im ok with boring holes through the frame as long as it wont weaken anything. Theres no makers mark on this machine, so ive had the hardest time identifying what is what, for the motor settings ect... for uccnc. The original pc was missing, so I dont know if the uccnc screen shot will help

2/5/21 #9: new to me cnc ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

em me a mcgrew six 3 six at msn dot com

send me some piccs of under the table , the controller (inside) and any other tid bits,, I might can tell you some helpful stuff my guess is uccnc software is married to its controller

View higher quality, full size image (969 X 929)

http://https://cncdrive.com/index.html

2/5/21 #10: new to me cnc ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

looks like they may have built this machine

http://shop.cncdrive.com/index.php?categoryID=89

2/5/21 #11: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

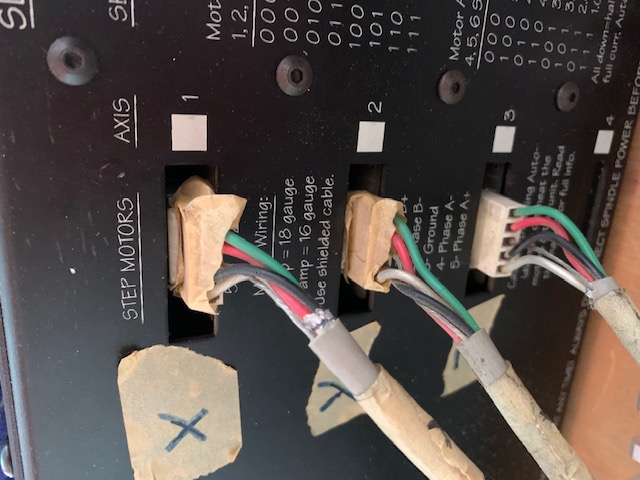

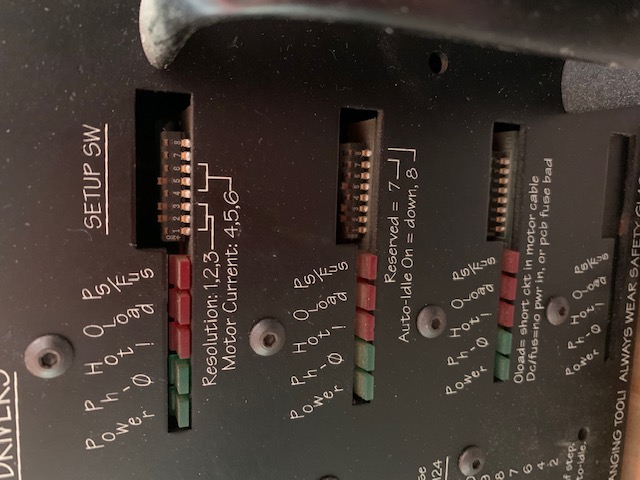

The table is aluminum. Ive attached pictures of the motor control box which still works amazingly...

Again any help I can get is great as I dont know very much...

View higher quality, full size image (640 X 480)

View higher quality, full size image (640 X 480)

View higher quality, full size image (640 X 480)

2/5/21 #12: new to me cnc ...

I question the 2,000 pound estimate, but from what I see, I would definitely add some angle bracing in the base. Either that or anchor it to a wall. I think you'll find a lot of machine wiggle from higher travel speeds to feed speeds. I'd also would recommend side plates on the z axis aluminum. You'll get flex in that plate because of that long reach. Especially when you put on a spindle. It will be an okay starter, but as said, don't put all that money in it. Keep it as a second machine when you buy a real commercial machine.

2/5/21 #13: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Thanks Rich. I did say almost a ton. my guess is between 15-1800 lbs. Behind that aluminum plate on the Z are a pair of Hiwin Rails as well. I really dont see a lot of flex happening there, but maybe. also there are two more long rows of boxtube under the table that are not seen, adding to weight and rigidity. So far the only time it has wiggled from start,stop at speed is before I leveled the legs to the floor. I do agree that there is a limit to what I should spend on this. But as far as i can see, if I keep the total price(including original purchase) under 12k, im in the win. There are no american made machines in a 4x8 in that price range, and from what ive seen in shopping for used, is that the big Iron all need repairs and upgrades just like this little guy, only all of their parts are proprietary and more expensive. Not to mention most of them appear to be used pretty hard in a production environment. Also theres no way a biesse rover will fit in my shop nor do I have near enough power going to my building.

2/7/21 #14: new to me cnc ...

I've run a CNC for around 20 years, I think you said you haven't. But if you don't trust my experience, that's up to you. A rail doesn't add strength because it's thin. You need width of material to add bending strength. I was an engineer at Caterpillar for 16 years, I know structural design and finite element analysis to engineer strength. I also ride bicycles for a hobby. I know that if there is no triangulation in the structure, it's not rigid.

2/8/21 #15: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Rich. You are correct I have zero experience,that just didnt strike me as a bending point... so you are saying I should add an aluminum plate gusset to the face of the router plate at a perpendicular angle to make the plate itself more stiff?

2/8/21 #16: new to me cnc ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

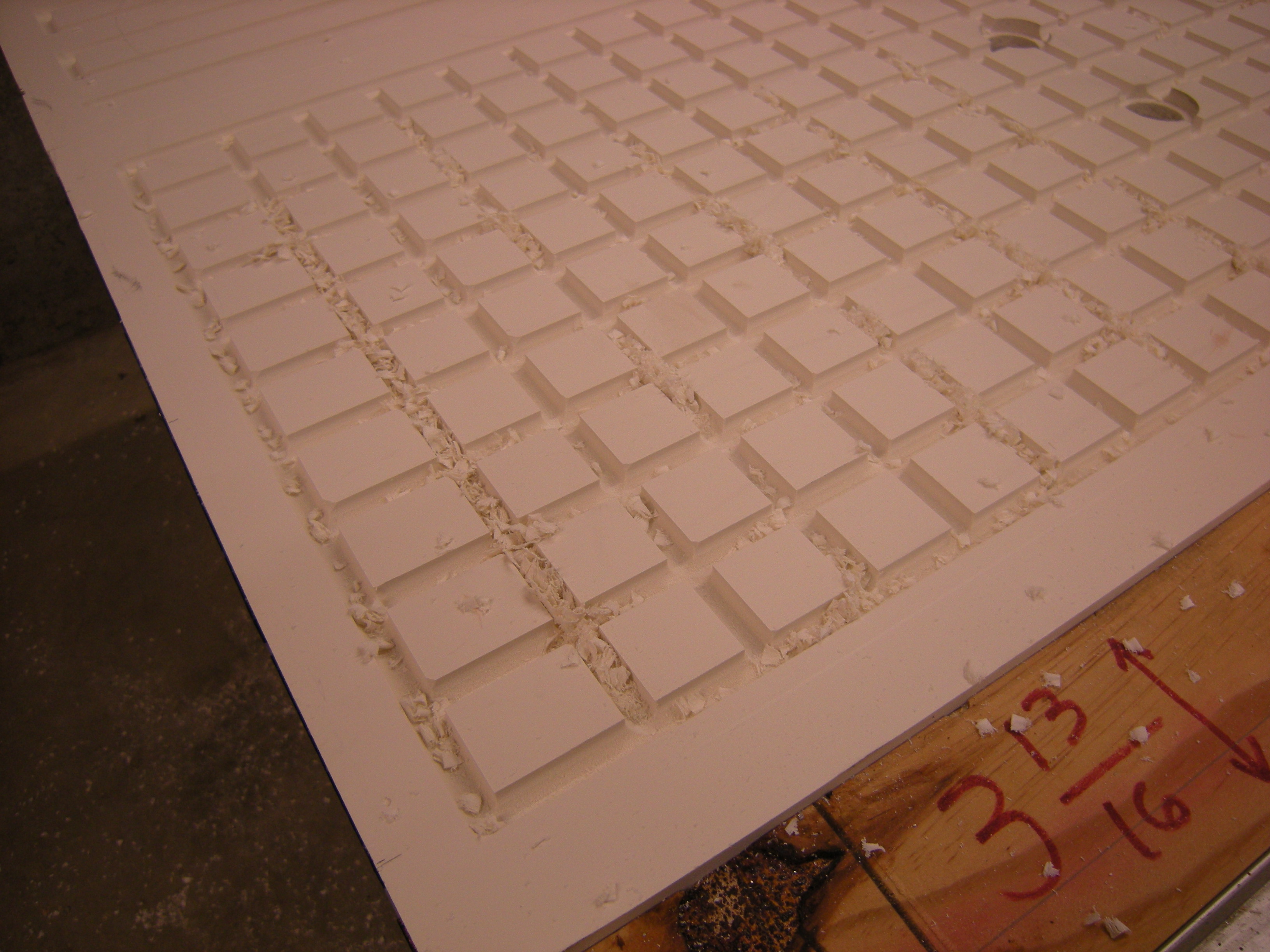

You can build your own relatively inexpensive through vac hold down system with sheets of 3/4" PVC (think Azek) and vacuum motors from Lighthouse enterprises.

I set my old Precix router up with four separate PVC grids and a vac motor below each one. Four switches allow me to run any of the 4 zones I need.

This is just a fun retirement machine but I am confident that shy of heavy 12 hour a day/6 or 7 day a week use the vac motors will do the job well for many years.

BH Davis

View higher quality, full size image (3264 X 2448)

View higher quality, full size image (3264 X 2448)

View higher quality, full size image (2048 X 1536)

2/8/21 #17: new to me cnc ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

A couple more photos.

Also, I wouldn't worry too much about rigidity of that table.....at least until it shows to be a problem. Looks plenty solid to me for that class of machine..

BH Davis

View higher quality, full size image (3264 X 2448)

View higher quality, full size image (3264 X 2448)

2/8/21 #18: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Thanks B.H. do you happen to have any links to info on building a vac table. Is there a file that I could download for cutting the grid ect...

Also, why is plastic better for the grid, as opposed to HDF or something like that?

2/8/21 #19: new to me cnc ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

You need a sheet product that is non-porous for the grid. MDF, HDF etc. while inexpensive are porous products. PVC is not porous. So while PVC is more expensive than the fiber based products it is substantially less expensive than aluminum or phenolic which are both non-porus and machinable sheet stock.

I'll see what I can dig up for you with regard to product links and cut files.

The shop vac motors have been widely used for hold down in the ShopBot world for many years. I have to confess that is where I originally learned of them. I've made a couple systems with them and both are still running strong.

BH Davis

2/8/21 #20: new to me cnc ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Here is one photo of the completed grid system. You can see more photos at the link below.

The vac motors are available through Lighthouse Enterprises. The motors he sells for this are his own design with long lasting brushes. Ballpark $135 each. I used 4 of the LLH7123-13 motors at 230v. One is mounted below each of my 4 independent zones.

https://www.centralvacuummotor.com/lighthouse.htm

Ward Bartsch is the fellow and he's very helpful.

A bunch of cut files went into making the grid panels and vac motor brackets. Let me know when you are ready and we can get together on the phone to figure out if any of these will be helpful. I think they will as UCCNC uses basic G-code which is what all these file use. I'm right now in the process of building a new UCCNC based control for my router. I'm at the point of tuning the servos so am pretty close to its being ready to run the machine.

BH Davis

View higher quality, full size image (3024 X 4032)

Vac Hold Down Photos

2/8/21 #21: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

Rad. Thanks B.H.

2/8/21 #22: new to me cnc ...

Website: http://www.mahnkencabinets.com

Website: http://www.mahnkencabinets.com

B.H. Do you happen to have any insight on how/where to begin with motor settings. in UCCNC. I have read the entire UCCNC manual, but theres not much there. I know your servos will be different than my steppers, but since my machine came with no info on the ball screws ect... Im a little lost. I think I made some basic calculations, but Im just stabbing in the dark.

2/8/21 #23: new to me cnc ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

I'm afraid I'm in much the same boat as you. That is I too am stumbling around in the dark trying to get the servos tuned. I've watched a bunch of videos and have an idea of what needs to get done but can only get close. I'm going to be calling in some help.

However many years ago I had a couple stepper motor routers. What I'm remembering is the primary item to deal with was the resolution. I think in the UCCNC Configuration window that would be the STEPS PER UNIT. I'd be inclined to start with that somewhere in the 1000 to 1500 range and see what you get. ACCELERATION could start at around 500 and again see what happens. I'd probably leave everything else alone as a starting point.

If the router moves with these settings then create a file that drills 4 holes at the corners of a 3' to 4' square. Repeat the file 10 times and see if the holes remain in the same place. They probably won't initially and you'll have to figure out if you need to increase or decrease the resolution accordingly.

BH Davis

2/21/22 #24: new to me cnc ...

A bunch of cut files went into making the grid panels and vac motor brackets. Let me know when you are ready and we can get together on the phone to figure out if any of these will be helpful.

|