Message Thread:

Software upgrade for generic Chinese CNC?

2/11/22

I am looking at buying a CNC from a generic Chinese company for our door shop that will pretty much be solely dedicated to making one or two piece MDF cabinet doors. It is a very beefy looking machine and appears to be made similar to some Euro machines but only cost $13,000. It comes with Artcam software which I have never heard of but I am told it can use any software as long as the software outputs Gcode. My question to you guys is can a software such as Mozaik or Cabinet Vision work with such a generic Chinese machine? I know itís a gamble but I have done a lot of thinking on this and have decided to go this route.

2/11/22 #2: Software upgrade for generic Chines ...

Tipper,

Cutting MDF doors requires a machine that has the least amount of vibration, which is why most door companies go for the big heavy iron machines to reduce secondary processes like sanding out blemishes.

I know of a company that buys the machines from China, then takes out the controller and replaces it with WinCnc or something similar. That is one possibility to resolve your concerns, but at $13,000 I am pretty sure they are using cheap Chinese motors and a spindle. Where is your service and parts going to come from and how long will you be down waiting on repairs?

2/11/22 #3: Software upgrade for generic Chines ...

False economy, no, no... no....no. Its not just the machine but the service.

-Do they have a technician in your area?

-Where is the parts inventory?

-Can you call for technical help in the middle of the day.

-Do you have any recourse if the machine is not what it appeared?

-Who made the spindle itself? What brand? Call a spindle rebuilder and get their opinion of it and if it can be rebuilt.

-What would a comparable name brand machine cost? If it is significantly less how is that possible? Maybe it is not comparable.

-I think the entry price for a machine to do what you want if you are a door shop and plan to do a lot of doors is $120K.

-If it seems to good to be true it probably is.

I have found over more than 20 years buying a cheap tool is never cheap.

Good luck!

Bill

2/11/22 #4: Software upgrade for generic Chines ...

Lots of good old heavy iron out there for $30k. Easy to fix and rock solid.

Look for a Fanuc control and you can get service anywhere.

I would also look for work other than MDF doors - decent integrated tooling can cost you $20K. Anything else is just pushing the cost down the line to the sanding area. Unless you spend $100K on a sanding robot.

2/11/22 #5: Software upgrade for generic Chines ...

Getting a post processor configured for their controller to other software will be the issue. Not unusual to have grounding issues and EMF problems with a cheap VFD for the spindle and controller. If you are really good with CNC, or have a local hobby guy who can make it jump through hoops, you're golden. But if you like turn key, don't consider it. You'll loose money fast not being in production.

2/12/22 #6: Software upgrade for generic Chines ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Ask them to send you a Gcode file. Then post it here and see if someone recognizes it as similar to something else.

BH Davis

2/13/22 #7: Software upgrade for generic Chines ...

several important point :

what kind of vacuum pump(best i think is copy becker 250 all the rest ..)

what kind of servo motor(be sure its not steeper)

what kind of controller(be sure its not fake mach3 ,because there fake hardware for mach3 its disaster)

do you have popup stopper around table to fix the board

check that the dust collector hood will not be less then 200mm(chines standard 100mm)if you want yours dust collector will do some work

be sure there greaze system not oil system if you don't replace bearing each month

good luck

if need any help can call me any time by watsapp 972504242775

***artcam that chines give its fake be sure you not got into trouble in usa when use it

***check shipping cost and tax ,i don't know to usa but china to israel 20feet container its 10k usd and as i know usa also have tax on chines machines

2/13/22 #8: Software upgrade for generic Chines ...

If you use Mobile Vac 2 Way Oil and have a manual pump or automatic oiler it's just fine. I retired after running a 5 axis Motionmaster and the bearings were as tight as new after 12 years.

2/13/22 #9: Software upgrade for generic Chines ...

rich

if oil was solution ,at least one of europ famous companies was use it

but there no even one western company use oil

**gantry type its much more sensitive to bearing issues

about machine parts i forgot one important point

reducer: be sure its reducer not timing belt and famous brand like shimpo or beiito

2/14/22 #10: Software upgrade for generic Chines ...

Website: westworldco.com

Website: westworldco.com

I bought a Chinese CNC a few years ago. No regrets. $25k included all the taxes, and shipping for a 5x10 with a linear ATC. I don't do MDF doors, but I encourage the poster to go for it.

I use an old version of MasterCAM, so I had to spend several days tweaking the post processor to get it working. Once you get the post processor working, you can run any program you want on top of it.

Lots of naysayers on this thread. But what do you have to lose? Let's say it doesn't work? Throw it away, buy a new one from China, and you've still saved money over buying an American version who bought from China and marked it up 300%.

2/14/22 #11: Software upgrade for generic Chines ...

yaakov,

You doubt my experience? I ran a 5'x10'x3' Z, 5 axis Motionmaster with a Fagor controller for 12 years using oil and manual pump on the linear ball bearing guides. It was the recommendation of that western manufacturer when we purchased the machine new. You have personal knowledge of every single western made cnc maintenance recommendations?

2/14/22 #12: Software upgrade for generic Chines ...

Motionmaster is now DMS and was purchased by SCM Group in 2018. The machine I ran is now called the Everglade.

https://dmscncrouters.com/product-lines/dms-essentials-5-axis/#

2/14/22 #13: Software upgrade for generic Chines ...

RichC

sure,im sure oil its not solution(im not taking about dirty ,this another reason why oil its disaster ,all machine become like pool of oil after several days ,and if you cut veneer its like kill it)

i not talking about every small producer i talking only the big leaders

Homag,Biesse,scm

also some smaller:

Busellato,Holzer...

not even one of them for many years never never think about oil as solution

oil is cant be solution its not stay in the bearing its liquid its not stay in the bearing ,its all go out

grease stay there

not even one of the bearing manufacture order its oil ,always greaze

2/14/22 #14: Software upgrade for generic Chines ...

RichC

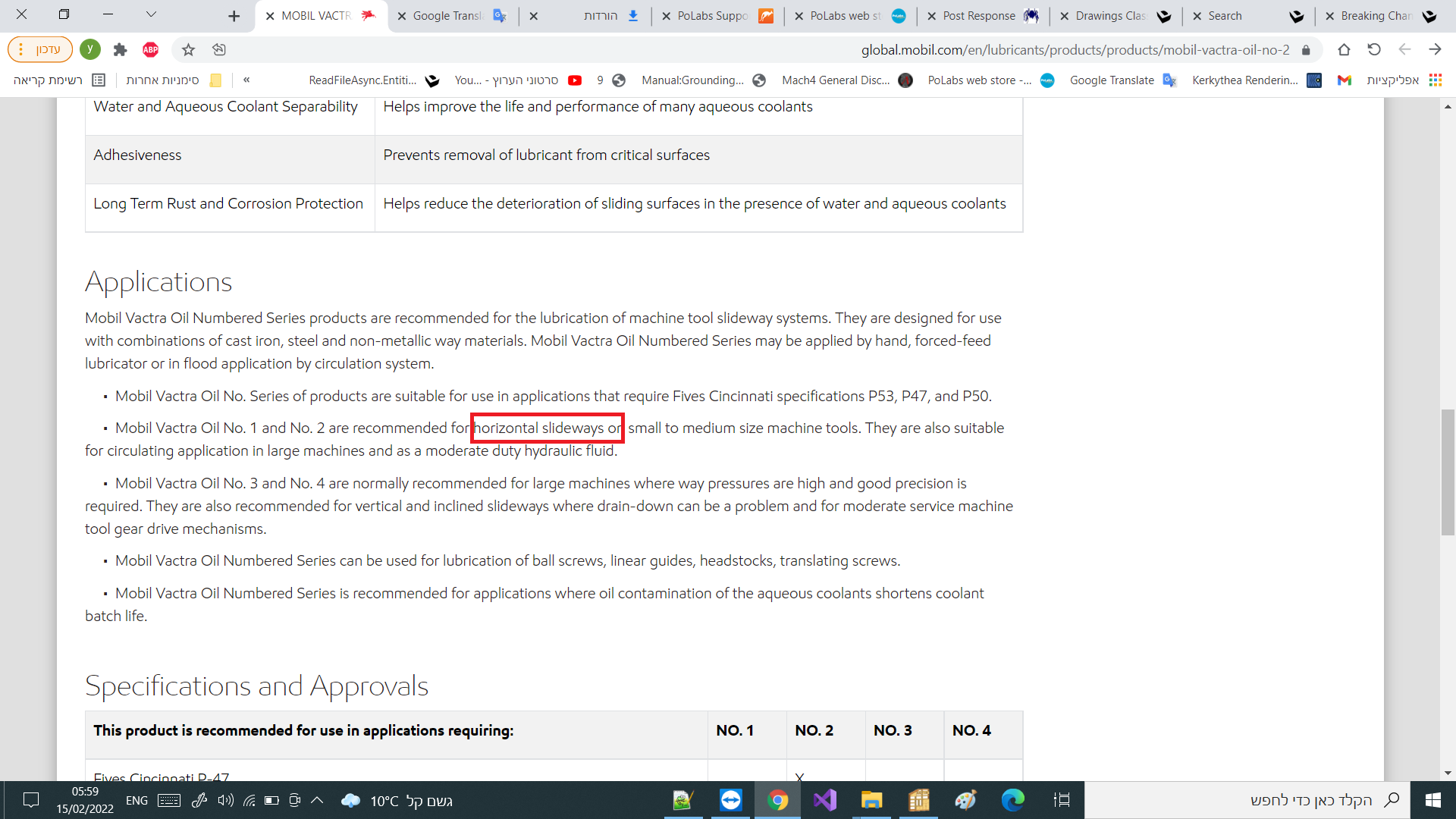

i was real interesting so i also look at mobile Vectra no 2 manual

it said there Only for horizontal guide(even the long axiss in cnc are not horizontal because they on there side )

so its real strange how the manufacture recommend you oil that not fit yours machine

View higher quality, full size image (1920 X 1080)

3/11/22 #15: Software upgrade for generic Chines ...

Website: https://forsuncnc.com/

Website: https://forsuncnc.com/

I suggest you consult a few more suppliers, if you want to buy an engraving machine in China, you can filter on Alibaba, Made in China, and other platforms, or you can directly search for the corresponding keywords in Google, or you can check this supplier's website, Jinan FORSUN CNC Machinery Co., Ltd., one of the professional Wood CNC Router manufacturers and suppliers in China, has been focusing on providing high-quality CNC Router Machines and solutions for worldwide customers for 20 years.

|