I will give you a bit different take from someone who has been a ground up general contractor for nearly 30 years and now running our shop (with CNC).

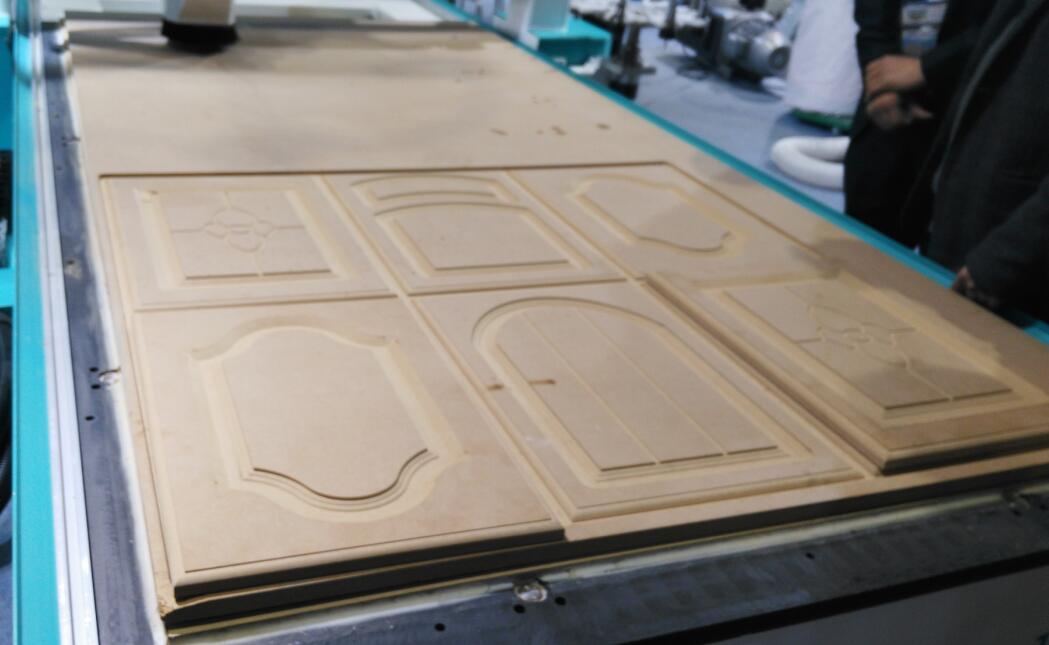

Integrating CNC into your construction workflow is not as simple as it may sound. You will have hours and hours of drawing and more hours than that if you are not generating highly accurate and detailed drawings for your jobs right now (without the cnc). Even though its an incorrect assumption you will find your guys saying that in the time it takes you to draw and run the parts they could make them old school. This may be true but the accuracy and repeat ability are not even comparable.

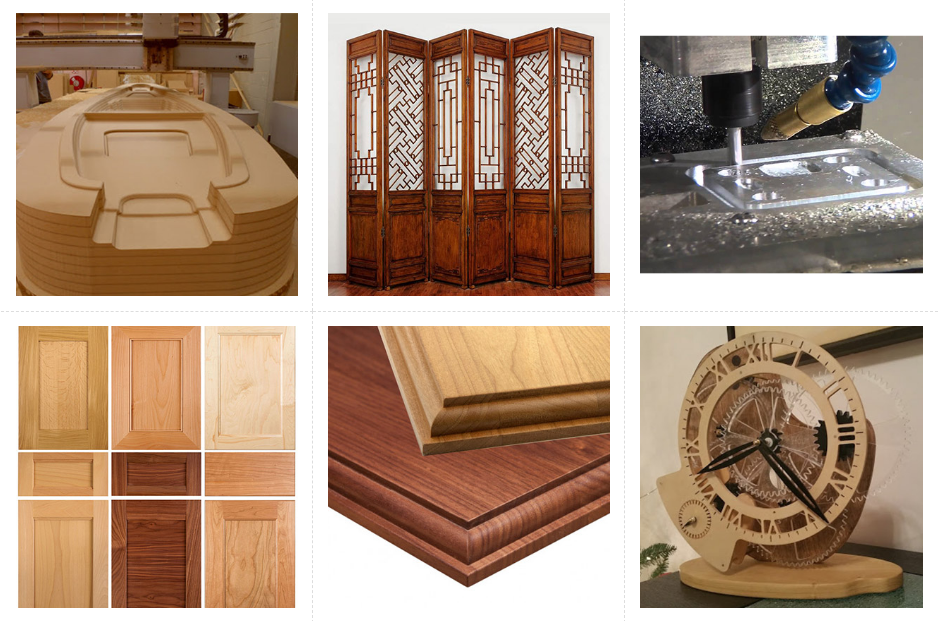

As a builder its my opinion that you need very specific tasks for a CNC to make it a profitable investment.

We dont build much anymore and are all wholesale shop work so the CNC works. I cant honestly say that would have been the case when we were doing ground up. Perhaps some cabinet carcass' or some garage/closet cabs here and there. Maybe some custom architectural work (bracketry, pergola's, gates, etc). But in my recollection of 30 years of field work I can clearly envision a $50K CNC sitting in the shop a large percentage of the time with the lights, air, and breakers, turned off to the machine.

My $0.02 would be dont waste your time if your not planning on having a dedicated man (salary) just drawing, programming, and running the CNC to feed the crew in the field. If you and your crew have to do all the field work and learn to feed the CNC (drawings and physically feed it) I wouldnt bother.