Vacuum fittings

12/8/21

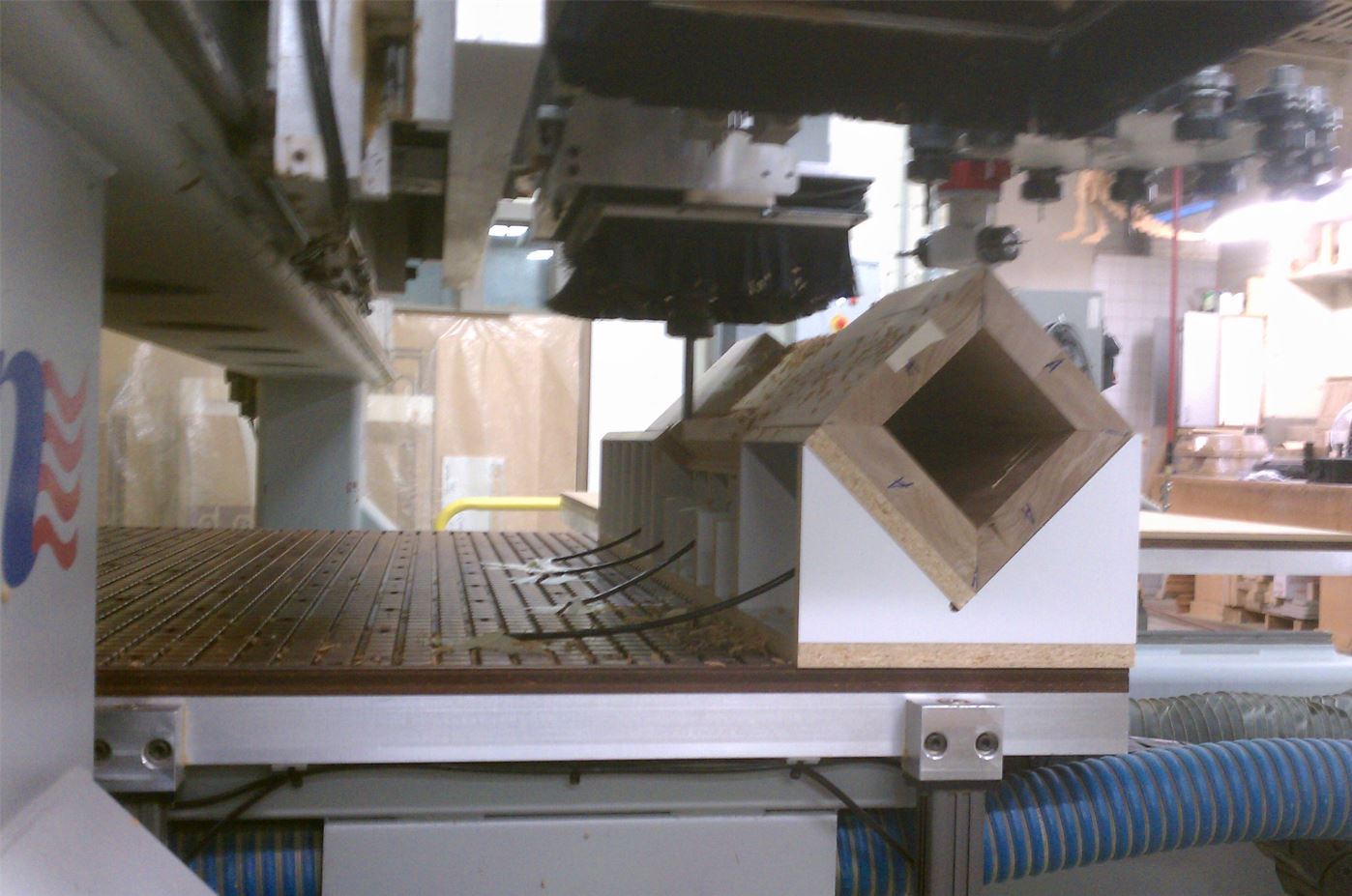

I want to plumb some vacuum into a fixture which for me is 3/4" melamine or similar. I want to pull the vacuum through 8mm tubing into the side of the panel. Does anyone have suggestions on a fitting to attach the tubing into the board? My goal its to have a functional fixture without having to remove the spoilboard from one of my worktables for one off custom hardwood parts. I figure I can endbore into the fixture to plumb my vacuum area, but attaching the tube to the fixture is my current issue. Thanks for any ideas. Similar to the attached picture, but attach the tube into the side of the panel since it will be sitting flat on the MDF spoilboard.

View higher quality, full size image (1398 X 927)

12/8/21 #2: Vacuum fittings ...

This place might help

800-878-7827

info@allstarcnc.com

13355 Grass Valley Ave

Suite B

Grass Valley, CA 95945

https://www.allstarcnc.com/

Jim

https://www.allstarcnc.com/

12/8/21 #3: Vacuum fittings ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

For fittings I've used 1/4" tubing quick couplers with1/8" NPT and 1/4" NPT threads. However this isn't going to work with Melamine as the air will bleed out the porous board. You would have to edge band it all the way around so as to hold the vaccum.

An easier way is to use architectural or industrial PVC. The white architectural PVC is available everywhere now (lumber yards etc.) if you don't have any in the shop. The industrial PVC is available from McMaster-Carr but is a great deal more expensive. I've used architectural PVC for these kinds of projects for a while now with great success. I even made the new hold down grid on my CNC out of it.

BH Davis

12/9/21 #4: Vacuum fittings ...

BH, Thanks for the response. I have 90° push disconnects coming to help with the tubing management, but I just shoved the vacuum lines into the horizontal bore all the way to the vertical bore and the fixture performed very well. I think I am set for my next hardwood part that needs to be held by a fixture. This will really save a lot of labor not having to remove the spoilboard and then plug all the vacuum holes in the matrix table.

View higher quality, full size image (3024 X 2268)

12/9/21 #6: Vacuum fittings ...

The vacuum holding strength is good enough to run the moulder on a part, but I will test tomorrow. I put the fittings on and its a little more manageable with the tubing. If anyone has any better ideas, I'm all ears.

View higher quality, full size image (3024 X 2268)

12/9/21 #7: Vacuum fittings ...

BH,

I tested it and it worked fine. I will include a link if you want to see it in action.

https://www.youtube.com/watch?v=LewNFhzt_iM

12/9/21 #8: Vacuum fittings ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Mike,

With your push to connect elbows I assume the tube is still inserted all the way into the Melamine. That would be why you have such good results. I had intended you to thread a push to connect threaded fitting into the melamine, which is what wouldn't have worked so well. Your plan is a great compromise on doing this with Melamine instead of a non-porous material.

BH Davis

12/15/21 #9: Vacuum fittings ...

Mike, are the auxiliary vacuum lines feeding your fixture a feature of your machine, or did you plumb that manifold into your flow thru vacuum pump piping?

12/16/21 #10: Vacuum fittings ...

Yes, those are auxiliary vacuum lines running from a manifold on the side of the machine. We bought that machine a year ago and I requested a manifold for vacuum and air on each table. You never know when that will come in handy so I added that to the spec. of the machine. May never need the air for pneumatic clamps, but I have needed to use them in the past.