SS, CNT, Freedom and My Machine Camaster are all in the same category of machines, I do exactly what you will be asking of yours and in 10 years my machine has yet to have a problem (only 1) which i was not back in operation within 48 hours (Fed ex timing).

The Camaster has lifetime support, You will need to learn your machine and operation, yet after a period of time some companies will require hourly rates for support.

Camaster provides a support forum which has grown to be probably the largest resource by members of any out there, there are literally hundreds of thousands of post and topics and 60+ thousand members who watch to learn and help at all hours. this comes real handy on a late evening or Saturday when you are trying to get something done and something happens you do not understand (and that will happen)

All of the machines you listed Cut well and the same. it is a matter of strategy beyond the HP or servos to produce good results. You will be doing a lot of study on bits feeds, rpms and materials, for this it will be good to have a lot of friends who understand your machine. when I started the cnc path in 07 I was basically illiterate to the (As I called it) the Voodoo language of CNC, yet the CNC made the difference to survive the recession and thrive for years since. it propelled us into work we normally would never have achieved.

Feel free to call and come see the machine, we have all that was mentioned (Big DC, Vacuum, Scissor lift for panels) it is always a good idea to go see shops with machines, go see the plant where they are built. Camasters Tables are built Machined in The same town as Assembly it is a truly US built machine. feel free to join the forum and ask questions it has been a great resource for thousands I am really proud of it Joey Jarrard (us routertools) Josh Glenn (CNC genius) and I are the founders of camheads forum. we have kept the forum autonomus of the company using machine owners as moderators to keep all needed info out of the hands of salesmen, there is a lot there I hope you will take advantage of this resource. Feel free to check out my website (mcgrewwoodwork.com) or facebook (Mcgrew Woodwork) and peer thru the photos of the shop, work and cnc.

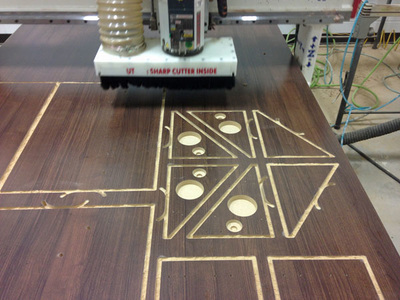

My machine is a 5 x 9 (I recommend a 5 foot width), there is nothing you cannot do with it as long as both ends and one side are open Mine has 15 tools (not needed but in my big 3d days was real handy) 7.5 hp spindle. I removed my beauty panels from the sides as cleaning is a bit#h under with them on we cut 40+ panels daily and a large amount of custom radius and 2.5 d parts

Good luck with your purchase, we have a policy to always mean well and warrant success for those who take these steps. it has been great for me and I pray that for you as well