Paul, Thanks for your comments. You got me thinking even more and I think I might have a clue. What do you think?

First, Water vapor at room temperature cannot dissolve or move water-soluble extractives. I do recall some chemistry about making solutions with water and non-hygroscopic chemicals.

Now here is my latest thought: Although liquid water is required to make a solution, with highly hygroscopic chemicals, we can have a liquid formed at under 100% RH. (Keep this thought in mind as you read further.)

Technically, water vapor is moving by diffusion, driven by a vapor pressure gradient. There is no way that a water vapor molecule can attach to any extractive molecule...there is no hydrogen bonding or molecular bonding possibility for them to attach. What is needed is a liquid that moves. This is reinforced by the Field discussion on p.5 and the Summary on p.7 in the referenced article. Further, even if vapor could move extractives, this would mean that extractives from one spot in the wood are traveling to another spot. Yet, the OP indicated that the wood veneer was discolored deeply.

It is my experience that when extractives move they are concentrated in a region at the surface, left behind when the liquid evaporates. That is, a liquid can carry an extractive to the surface of wood and then be evaporated, leaving the extractive behind, creating a concentration at the evaporation site--the surface. The extractive than can oxidize forming a new color.

Note that if indeed vapor could move extractives, we would see this occurring time and time again, as vapor is always changing in wood products.

Moisture vapor only moves through wood when there is a difference in vapor pressure. So, what force is creating a substantial difference in vapor pressure between the discolored and normal colored wood? Certainly, liquid water entering on the edge will often make a difference, but this is not likely in this case. So, how do we get a vapor pressure difference that will last for a long enough time? Overall, the humidity at the edge and at the face would seem to be, on the average, identical.

So, let me throw in this possibility. We know that highly hygroscopic chemicals will form a liquid at less than 100% RH. (Example: Table salt will attract enough vapor to become liquid and then cake or harden.) So, is there a highly hygroscopic component in the adhesive or core material? Or maybe it is associated with the edge banding? It would attract liquid moisture at less than 100% RH. With a liquid, I can envision some small movement of chemicals and, more importantly, some changes in chemicals (chemical reactions).

As an example, the formation of iron tannate stain in wood occurs when there is tannic acid, iron AND LIQUID WATER. Humidity alone does not cause or create this reaction. In other words, an iron nail in oak does not form iron tannate until liquid water is present. But we do know that a highly hygroscopic chemical (mainly a salt) can form liquid water which can be used to make this reaction occur even when the humidity is under 100% RH. I do believe that some cedars have such chemicals and so are able to create enough moisture so that fungi (mold) can grow on the wood surface even at humidities under 100% RH.

I am not convinced that light is a factor, as we know that light only penetrates into wood about 1/100". How do we get the color deep into the wood?

I think that with the presence of water liquid, chemicals are formed that are being oxidized, which would happen at the surface and below the surface.

I am still not sure why we do not see this more often. Is it possible that the doors are being cleaned with a chemical cleaner by the maintenance staff? How can entry doors and dresser drawers have the same effect? What is in common? Maybe the adhesive or the core of ??? Why only in this case and not all over the island?

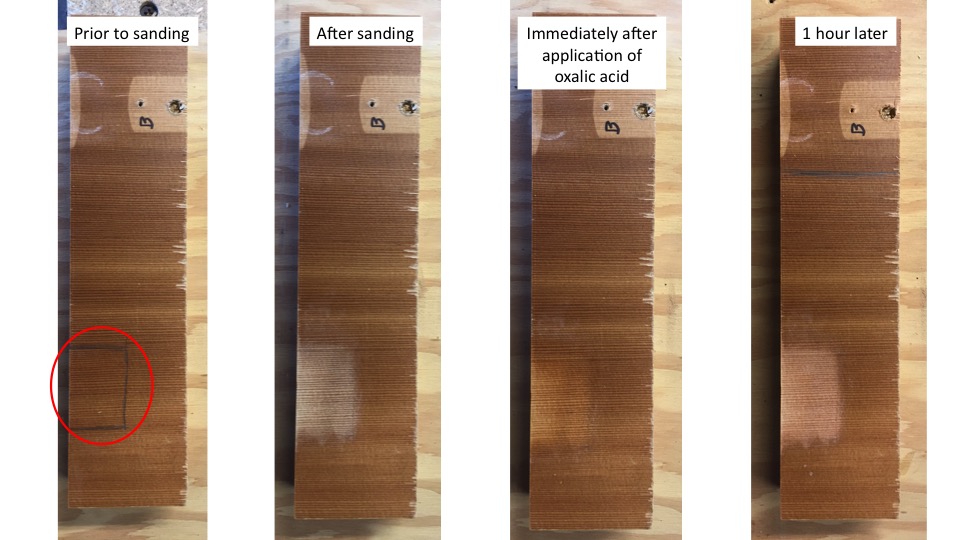

One suggestion. Put some oxalic acid (also called wood bleach) on the stain area (perhaps first sanding through the finish). If indeed this is an oxidation reaction, you will see an almost immediate lightening of the color.