Message Thread:

Replacement Shaper Fence

3/17/21

Website: vermonthardwoods.com

Website: vermonthardwoods.com

We have a 40 year old Rockwell/SCMI T120C shaper. It has had a very long and pretty hard life. We finally gave up on swapping out 3/4 and 1-1/4" spindles after about 15 years of using a crowbar to pop the spindle out because the threads on the loosening mechanism were stripped, and replaced all the 3/4" cutters with 1-1/4" (of the ones that we actually use).

The problem we are having now is the "spindles" that hold the fence pieces. There is so much slop in them that getting infeed and outfeed parallel is becoming an exercise in futility.

There's a shop nearby that restores old machines, mostly gearshapers and other metal working types. We had them make a new shaft for our profile sander a couple years ago and they did great work. However, I've talked to the guy three times, and he came and looked at it once. He seems interested in fixing it but isn't following up. I even offered to buy him lunch once when he mentioned that he likes the place right around the corner from us...

That and the fact that I can easily imagine it costing $2,000 makes me wonder if there is a "generic" fence out there that would work. I've looked around online a few times but haven't found anything. All we need is a very basic one - infeed and outfeed with screw forward and back, the ability to move the individual pieces towards and away from the cutter.

We don't need the same attachment point - we are willing and able to drill and tap new holes in the table if necessary.

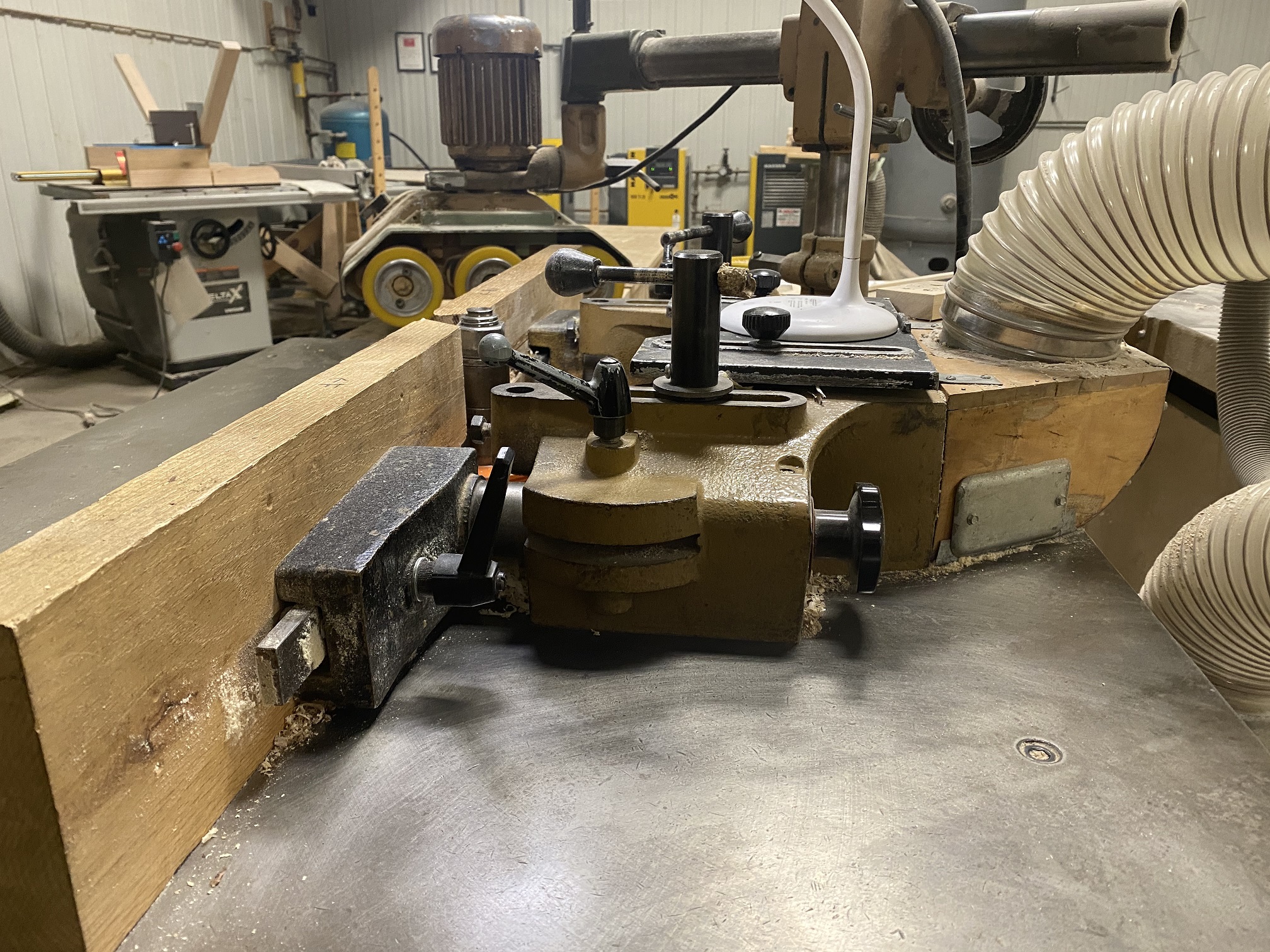

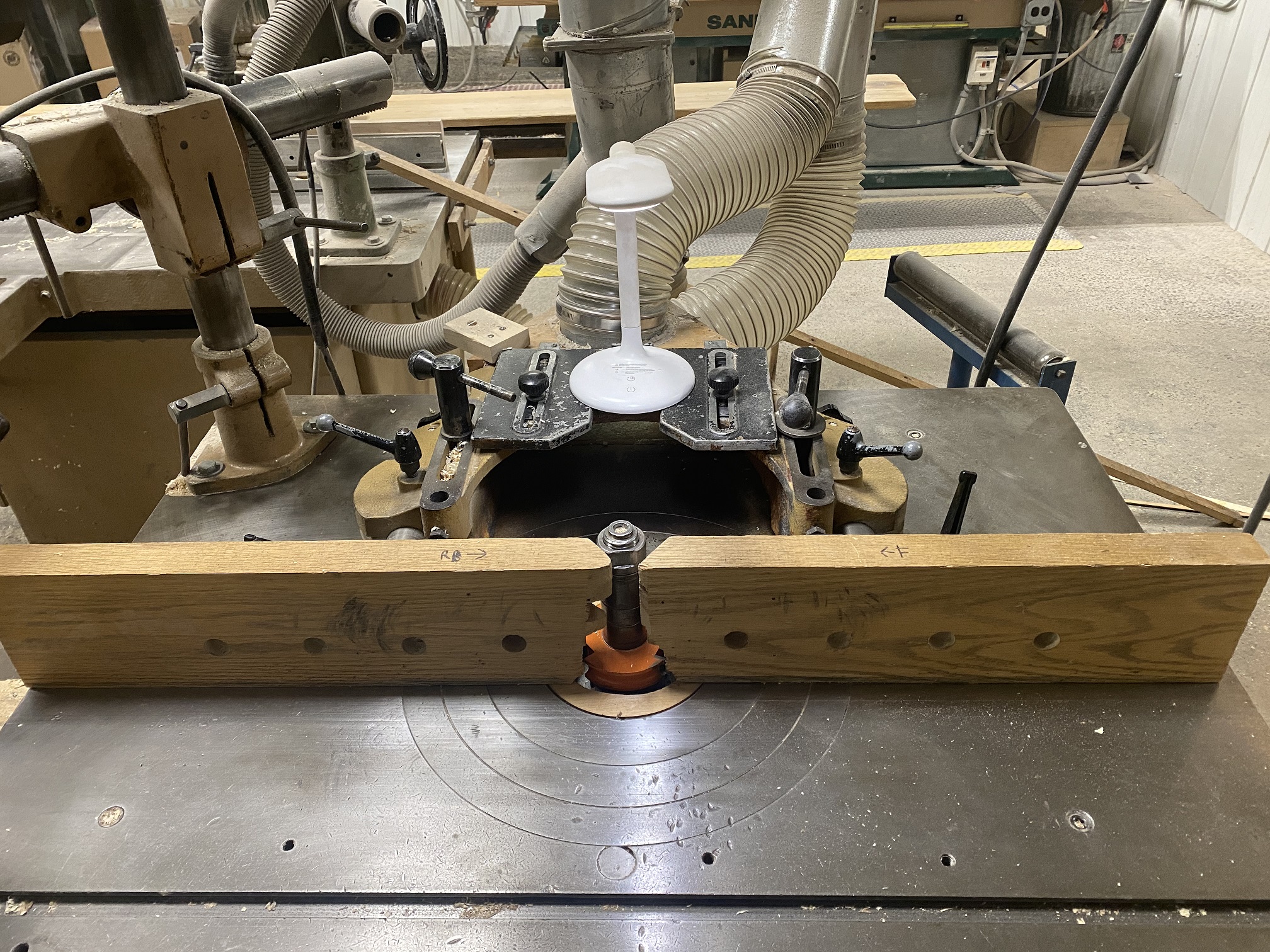

Pics attached of the OEM one.

View higher quality, full size image (2016 X 1512)

View higher quality, full size image (2016 X 1512)

3/17/21 #2: Replacement Shaper Fence ...

David Waldman:

For the shaper that I own I made a plywood fence that ran the full length of the shaper. I cut out an area so that the cutters have clearance, but still left the fence body as an integral unit. I set up some angled rabbeted pieces onto the fence body such that a dust collector hose throat plate would fit in the rabbet and be securable.

I created a number of plywood rips, with the back scooped out on the bandsaw, that I would screw to the fence body such that the plywood rip stood vertically, and the scooped back spanned the cutout in the fence body that allowed for cutter clearance. The fence body is held onto the shaper with two C-clamps.

I would set up whatever cutter I was using, clamp one side of the fence body, turn the shaper on, and pivot the fence into the cutter through the scooped back until the full cut that I was after emerged. Clamp down the other side of the fence body, and run the stock.

If I needed to take up the cut differential on the outfeed side and prevent snipe, I would spray contact some vertical grade or horizontal grade plastic laminate to the outfeed side, and roll with it. Use a new scooped rip of plywood for each run if needed.

I found the manufacturer's fence to be more trouble than its worth, much as you have, and spent a couple of hours and some scrap plywood to make a fence that has worked well for me for 20 years.

Good luck.

TonyF

3/18/21 #3: Replacement Shaper Fence ...

Do you need the split fence? If you don't, buy some aluminum extrusion and make a solid fence. If you need the split fence, watch for parts on eBay.

3/18/21 #4: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

We do need separate in and out feed fences, as most of the time we are actually removing material from the edge, as in a bullnose.

I suppose that TonyF's suggestion could work, as long as we made "fillers" for the outfeed that were quick and easy to attach and remove, and we standardized the amount we leave the pieces over. I will have to think long and hard about that.

The original fence is very well built and worked excellent for many years. For the first 20 or so years of its life the shaper was used as a moulder, and ran mostly short runs (less than 1000 LF) almost constantly day in and day out. We ran profiled victorian casings, crowns, you name it, up to around 5" tall. I really would love to just buy a replacement...

3/18/21 #5: Replacement Shaper Fence ...

Website: http://www.sogncabinets.com

Website: http://www.sogncabinets.com

I'm a big fan of an outboard fence when removing material

3/18/21 #6: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

We use an outside fence when practical. Kind of hard to use for stair treads with mitered returns... :-)

3/18/21 #7: Replacement Shaper Fence ...

A repair may be as simple as reaming out any oversized holes and having bronze bushings pressed in. Any machine shop can do that. It will take time to jig up though, to keep everything square.

3/19/21 #8: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

Rich, I believe you are right and that is what I was expecting. The possible additional complication would be if the shafts have also worn unevenly, and would have to be turned, which could be kind of tricky, I expect.

The thing is, we use this shaper almost daily. We're in the middle of nowhere and I don't know of any other machine shops nearby. Adding 2-3 days for shipping would be really tough.

3/19/21 #9: Replacement Shaper Fence ...

David Waldman:

While what Rich recommends, or some variation of it, is the right thing to do for a more permanent solution, one thing that might work is to try to adhere some shim stock, either to the spindles where the wear on the spindle housing seems to be, or on the spindle housing itself.

Run some narrow strips of the appropriate thickness shim stock along the length of the spindle such that it is snug in the housing, or in the housing itself so that the spindle is snug. I would guess that all of the the wear is in the housing, which is probably softer metal than the spindle.

After that, a fly cut of the wood fence on the joiner might get everything into a "relative parallel" by removing the initial skew that may result in not having the metal block that the wood fence slides on be perpendicular with the fence spindle relative to the new shimmed travel trajectory.

Just thinking about something that you can try yourself without losing a lot of downtime or money.

Good luck.

TonyF

3/19/21 #10: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

TonyF - that may work. Thanks for the suggestion.

3/20/21 #11: Replacement Shaper Fence ...

$2000 is absurd. Any good machine shop could fix it in a couple of hours.

Before you make any decisions think about how to make what you got work for awhile longer.

There is typically a large range of adjustment on those fences. There will be unused thread on the screw. Probably at each end. Run the fences out to their extremes. One of the fences will have more slop. Make that the passive(fixed) fence. Lock it tight. Never move it. Like the outfeed table on a jointer. Now you are dealing with one fence on new threads.

You can also induce drag into the threads. Plastic bolts of various kinds are available on McMaster’s. Get a 3/8-16 nylon bolt. Drill & tap the casting in a place where the plastic will drag on the thread or shaft. It works like a nylock not if you put it on the threaded area.

99% of the time those fences are left in the middle of their range. All of the wear occurs in that area. Generally only the infeed fence is adjusted on a regular basis.

3/22/21 #12: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

Adam, maybe I wasn't clear in my description. It's not the thread on the screw that's worn (well, it is, but that's not the problem, and easily compensated for), it's the 2" diameter shaft.

And you can't put it in place and lock it permanently. It's not a jointer - every cutter has a different diameter.

As for how long it will take to fix it and what it will cost, I don't really know. But I'm pretty sure it will be a whole lot more than "a couple hours". First, two holes have to be bored that are flat and parallel. Then bushings need to be pressed into place. Then, possibly, the shafts have to be turned and lastly, the bushings will need to be reamed to size. I'm not a machinist, but I do know that working with metal is slower than working with wood, and much more precise. I could see it taking all day to do it if it were wood. It is not a quick and easy fix, or I'm sure the local guy would have already done it. He's procrastinating because it's going to be complicated.

3/23/21 #13: Replacement Shaper Fence ...

David,

Your 2nd explanation is much clearer.

I’ve got thousands of hours on shapers. You’ve got a gross adjustment(slotted handles) and fine. You should be able to fix the outfeed fence in an average(middle of its adjustment) location. Grossly moving the fence in an out will deal with the various size cutters. As long as the infeed fence is adjustable you should be able to make it work. Add drag on the threads with plastic will help as well.

The obvious solution is to run everything off a bearing, fixed fence, shimmed out feed fence(piece of laminate glued with spray adhesive, or an outboard fence.

Just trying to help

3/25/21 #14: Replacement Shaper Fence ...

The last time I had a shaper fence I was trying to replace I ended up buying a dead shaper for the fence.

I've occasionally seen orphaned fences on ebay (not very often).

If you realistically think it will be $2000 to fix (certainly possible depending on your local machine shop rates) you would likely be farther ahead locating a replacement shaper and selling the current one to someone who didn't care about the fence issue.

3/25/21 #15: Replacement Shaper Fence ...

Website: vermonthardwoods.com

Website: vermonthardwoods.com

Jared, it may come to that.

I actually was looking at used SCMIs and thought about buying one just for the fence and then selling it with our old fence.

2/23/22 #16: Replacement Shaper Fence ...

With the back scooped out on the bandsaw, that I would screw to the fence body such that the plywood rip stood vertically, and the scooped back spanned the cutout in the fence body that allowed for cutter clearance. The fence body is held onto the shaper with two C-clamps.

|