Message Thread:

4 head moulder problem

1/23/22

We have a sicar 4 head Molder which we just got running. The pics show an odd pattern on the wood on the underside and the right edge. There is an edger on the right. The bottom planer head is a terra 4" the rest are spiral heads any ideas as to why we have this pattern and not smooth! Feed rate is 6 m per min

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

1/23/22 #2: 4 head moulder problem ...

Looks like not enough feed pressure and the board is stalling intermittently.

1/23/22 #3: 4 head moulder problem ...

It looks like you aren't taking enough material off to remove saw marks.

1/23/22 #4: 4 head moulder problem ...

Oh! Perley, you are correct! I just remembered I reduced the right side cutter amount, now to figure the bottom! Those marks are actually from the right edger

1/23/22 #5: 4 head moulder problem ...

It also looks like you need to check the side spindles for square, the cut in the picture looks out of square. Also make sure the feed rollers are running true and slightly toward the inboard fence.

1/26/22 #6: 4 head moulder problem ...

There could be a few issues creating what you are experiencing. Try checking the pressure shoe. I put a link step by step instructions. Let me know if that works. If not we can try something else.

I hope it helps

https://www.mr-moulding-knives.com/information/moulder-pressure-shoe-calibration

1/28/22 #7: 4 head moulder problem ...

More info. It seems the edger unit is making the wood jump. The edger corner also fills up with shavings despite lots of suction from the dust collector. I would almost say that the vertical knife is the wrong size but I could be wrong. We have the lubrication unit now working and the top pressure good. Still not as smooth as we expect off the joint. Thoughts? What about a vibrating drive belt? Would that telegraph through the spindle? Bad bearings? How to check them? The ripple is still 15 mm apart.

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

1/28/22 #8: 4 head moulder problem ...

Thanks for the pics, that helps take us to the next stage. Tell me a little about what after the rebate cutter, is there a guide fence attached to the bedplate after the bottom spindle. Please read this other article and tell me if it applies, if it does, follow the instructions, that could help.

Another pic might help, run a piece of lumber into the machine and stop 3" after the right cutter head. Shut the machine off with the wood in the machine. After the machine safely shuts off, raised the feed beam and take the wood out. Flip it over and take a picture. This will let us know what happens at each stage of the cuts.

Hope that fixes the issue

https://www.mr-moulding-knives.com/information/moulder-rebate-rabbet-cutter-alignment

1/29/22 #9: 4 head moulder problem ...

Dave

What are the RPMs of the machine?

Twenty feet a minute may need to be adjusted. If 6000 rpm your good.

Let's get the feed rate inline before we go down the bearing road if not needed.

The rebate cutter still needs to be addressed though, it might need alignment, it's a commonly overlooked problem if you don't know how to adjust it. My guess would be the axial adjustment of the bottom spindle need to be moved back to keep from hitting the small rebate guide fence, once the wood hits the guide it pushes the board away from the right cutter head as well as raising the lumber leaving a mess on the bottom and leaving saw marks not milled off by the right cutter head. Or the rebate guide is too far out of alignment with the first right cutter head. Post a pic of the area between the first bottom and the right cutter head bedplate. I am looking for a small guide fence.

We will get to the bottom of it, lets's due to the basics before spending money.

All the best

Russ

https://www.mr-moulding-knives.com/information/moulding-knife-marks

1/29/22 #10: 4 head moulder problem ...

Dave

Please check with the Manufacture on the size of the rebate inserts. If they are too small in height to cut enough wood away to get over the top of the rebate guide fence that the same issue will happen. The board hits the rebate guide (if you have one) and raises the lumber off the bedplate.

Hope that helps

1/29/22 #11: 4 head moulder problem ...

Thanks Russ. I will go over those points with it today. The articles are very helpful!

Rpm is 6000 with 4 knife head. 6m/min which is 19.68 fpm. I can also run it at 38 fpm. I'll run a piece like you suggest away from the rebate cutter.

1/29/22 #12: 4 head moulder problem ...

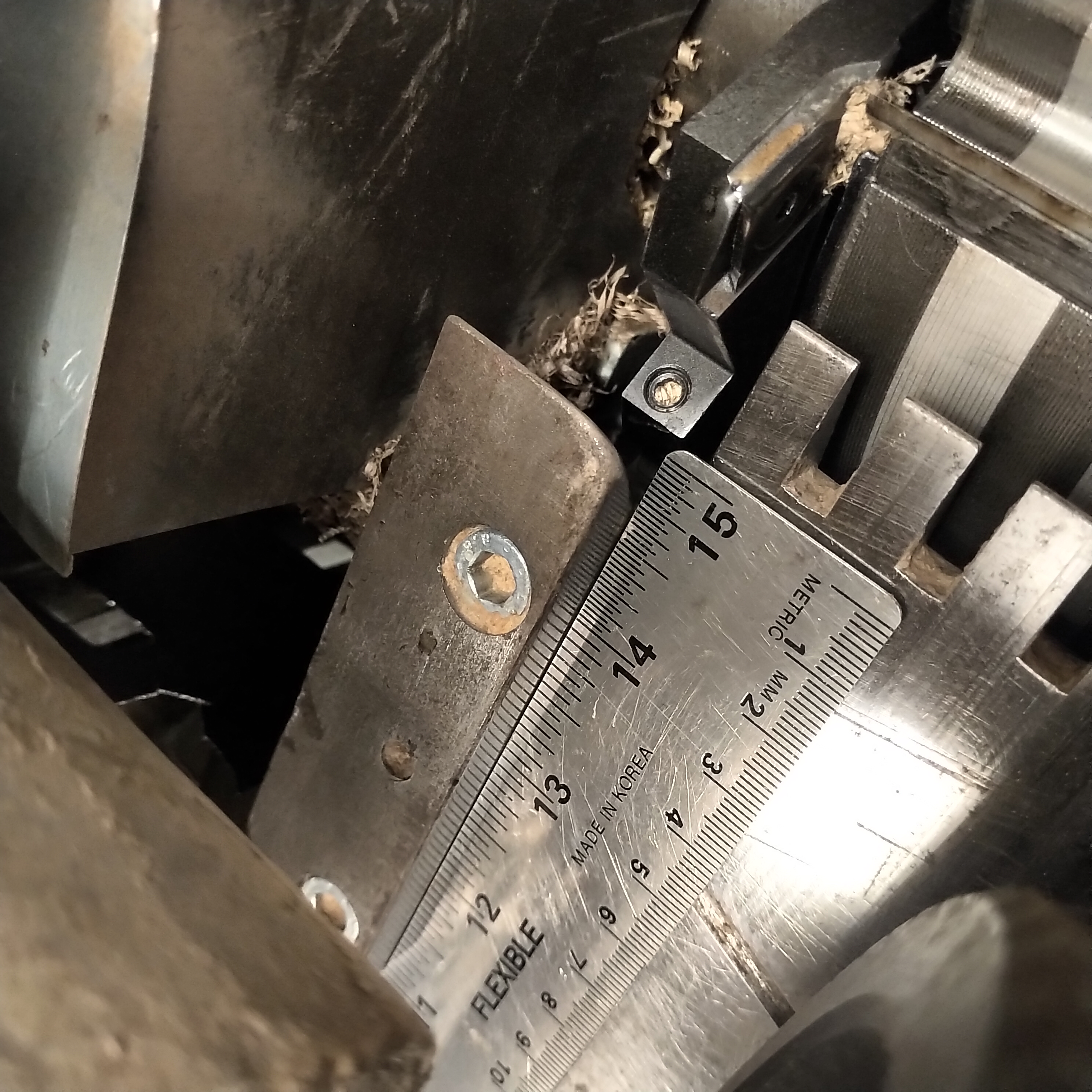

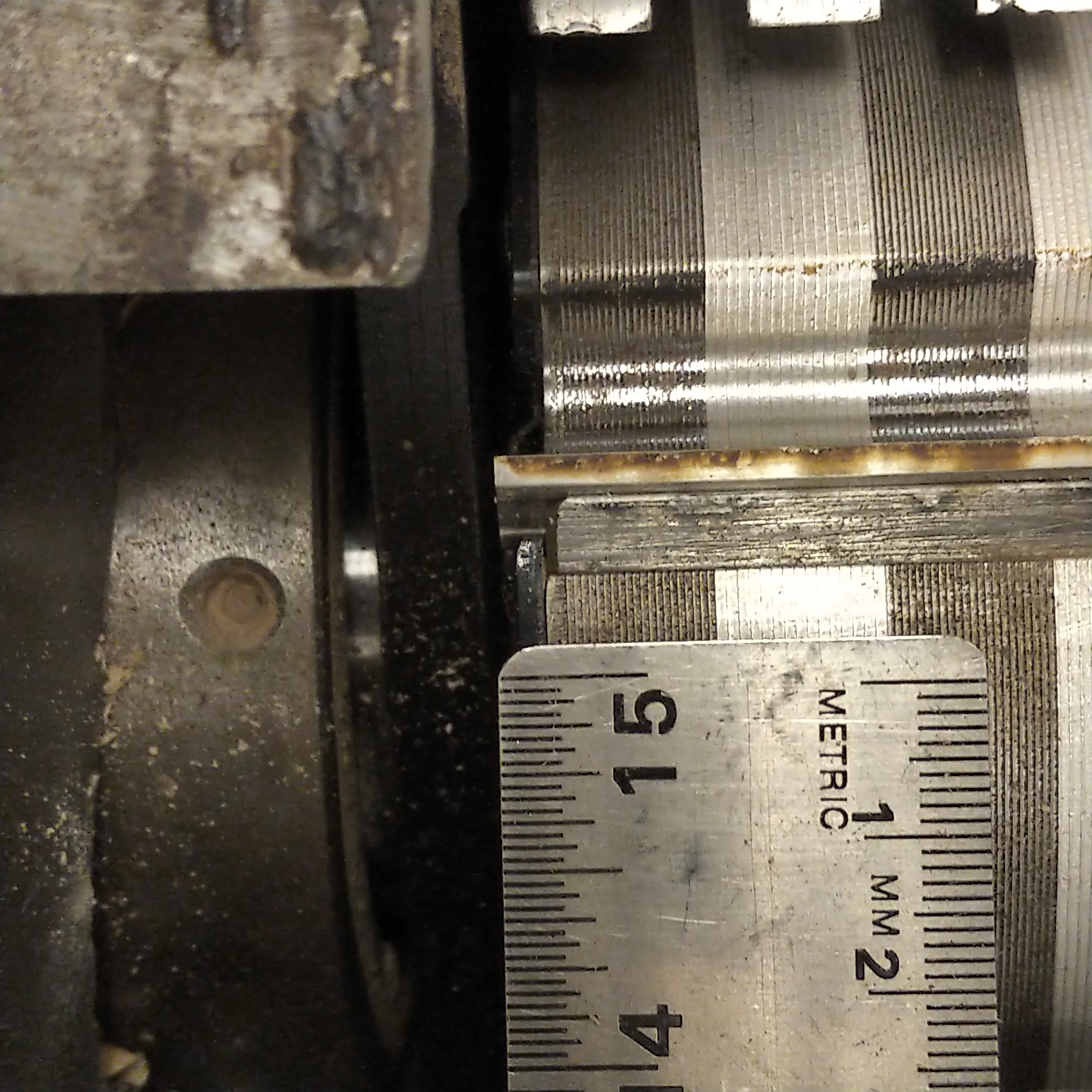

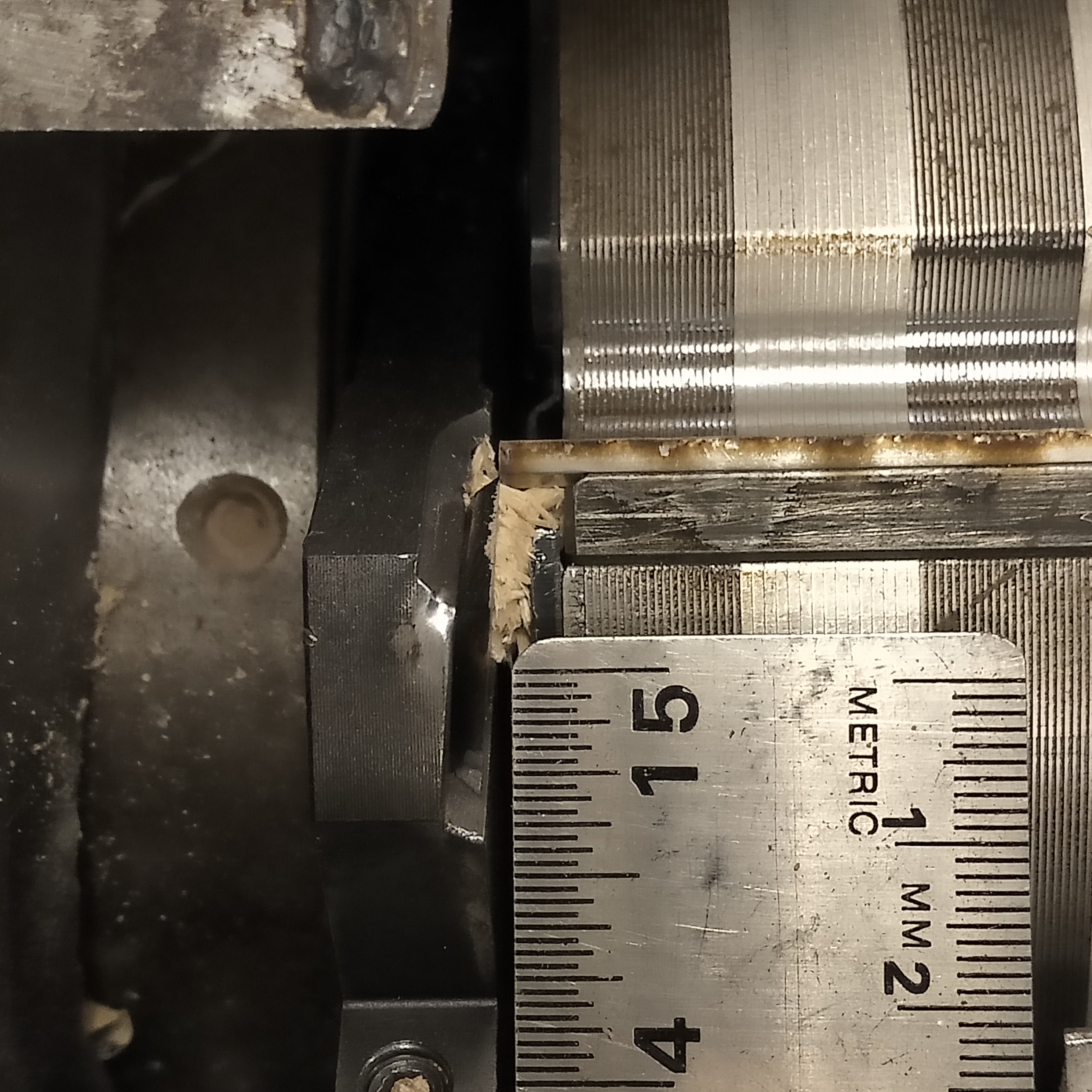

Ok. Checked rebar cutter and all good radial and lateral. Made a slight alignment. Lots of room to go over the shoe. Ont thing though, the shoe is exactly in line with the right fence past the first vertical spindle.. As per pic

Tightened belt to main joint head, helped a bit. Next pic is the pattern i see off the bottom head running at 12mpm.

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

1/29/22 #13: 4 head moulder problem ...

Is the air pressure on the feed rollers 40lbs?

Is there a star knob on the first set of rollers, if so make sure the roller are all the way down, feel free to call me if you wish

1/29/22 #14: 4 head moulder problem ...

The vertical cutter on the rebate cutter should lightly touch the straight edge in your picture. How much are you taking off on the infeed table fence? It should be around 1/8".

1/29/22 #15: 4 head moulder problem ...

Dave

Would you please provide a pic from the infeed of you machine, I would like to see the a portion of infeed table, rebate cutter and the right cutter head. I am not familiar with the Sicar machine. I might help see what you have going on.

Thanks in advance

Russ

1/29/22 #16: 4 head moulder problem ...

Dave

It almost looks like that fence you have the ruler on in the pic is the fence and not a guide fence for the rebate cutter. If that's the case do this,

Put a straight edge flush to the fence behind the right cutter head.

Adjust the right radial cutter head until the straight knife barely touches the straight edge.

The fence in front of the right cutter head should be behind the plane you just set, by the exact amount of wood you want the right cutter head to remove.

I hope this helps make the saw marks go away.

You should have a lateral pressure element that pushes the lumber to the fence attached to the left cutter head assembly. this should eliminate the chatter we are seeing from the sides.

The bottom chatter is telling me there is not enough feed roller pressure to hold the workpiece on the bedplates.

I am running out of options :)

1/29/22 #17: 4 head moulder problem ...

2 pics wheels on and off.

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

1/29/22 #18: 4 head moulder problem ...

Russ I think I have the side rebate cutter aligned well now. Nice smooth cut on the side when removing 1/8" last task is bottom. I will put more pressure on the feed rollers. When the machine winds down in rpm you can hear a zum zum zum zum zum. Of the bottom cutterhead. About 1/3 second apart. Very odd.

1/29/22 #19: 4 head moulder problem ...

One more thing, I have top hang the knife top the right on the joint head like this so there is no gap between the rebate cutter and the main knife.

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

1/29/22 #20: 4 head moulder problem ...

Dave

I think I see the problem,

The knives look very dull. The motor will still spin the cutter head even with dull knives. What happens is the wood is being plowed into a dull knife and lifts the wood off the bedplates to crawl over the top of the cutter head instead of cutting thru the wood, creating the ripple effect. The sound must be very loud when milling, the machine is talking to you begging for a sharp knife:)

Please replace or sharpen the knives, I think you will see a huge difference,

The other issue would be feed roller pressure, how can you control the pressure on the rollers?

Were getting there

Have a good evening

Russ @ MR

1/29/22 #21: 4 head moulder problem ...

I have a question that may sound a bit off but I want to check to make sure its aligned correctly.

If you place the straight edge on the bedplate after the bottom head is the knife just barely touching the straight edge?

I know is basic but I have to ask, sometimes common knowledge to me is not to others.

Thanks

Russ

1/29/22 #22: 4 head moulder problem ...

Yes - have a very flat ground bar and I set the cutterhead/bedplate so that the knives just move the bar about1/8" linearly. We do the same with our felder jointer, knives are just a thou higher than outfeed. New set of kinves arriving Monday morning.

I almost feel like I want to go back to the 4 knife head where the knives are ground rather than the tersa. We process about 1500 bf per month. Always stock that is 2-1/2 wide x 13/16 finished dimension.

Another thought is that perhaps the rebate cutter should be rotated in ration to the cutter block so that the vertical carbide is not near one of the cutterblock knives. Seem to get a solid buildup of shavings right in the corner.

View higher quality, full size image (2976 X 2976)

1/29/22 #23: 4 head moulder problem ...

That's a good idea on the rebate cutter, I think new knives will be a big help. did that rebate cutter come with the machine? It just look like a mismatch, never seen a gap so big between the two cutters, there must be a shoulder on the cutter head or something like that.

I would be interested in seeing the wood after you change the knives.

have a good weekend Dave

Russ @ MR

2/3/22 #24: 4 head moulder problem ...

Good Morning Dave

Curious to see if you solved your problem with the new knives?

Thanks

Russ

2/3/22 #25: 4 head moulder problem ...

Waiting on new blades to arrive in before re-evaluating. Should be either today or tomorrow. I'm changing all cutters on the jointer and rebate cutter. Also took off the head and re-use the position of the rebate cutter relative to the counter knife. That helped shavings control. Will clean of residue on all other heads. Smal steps and I am seeing improvements.

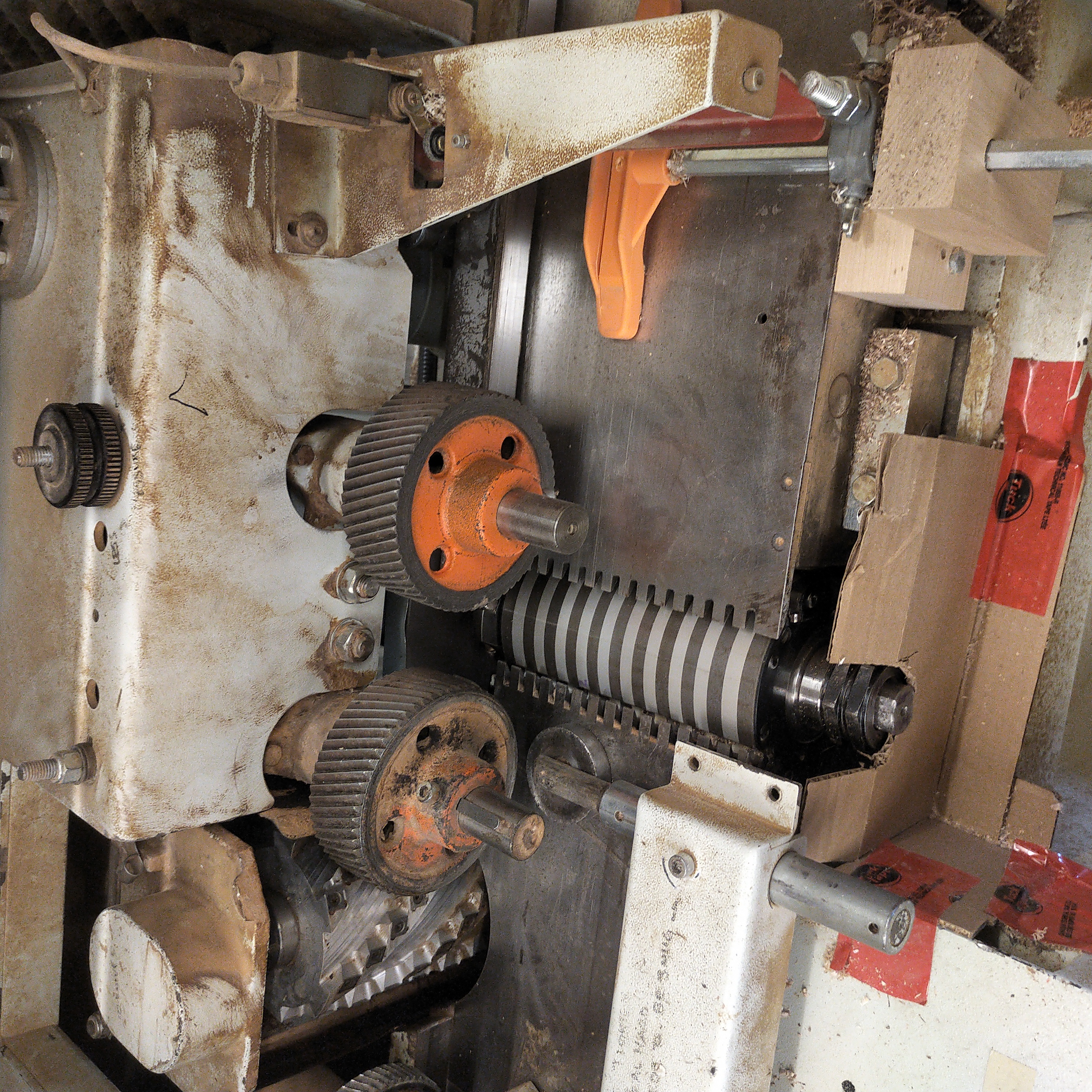

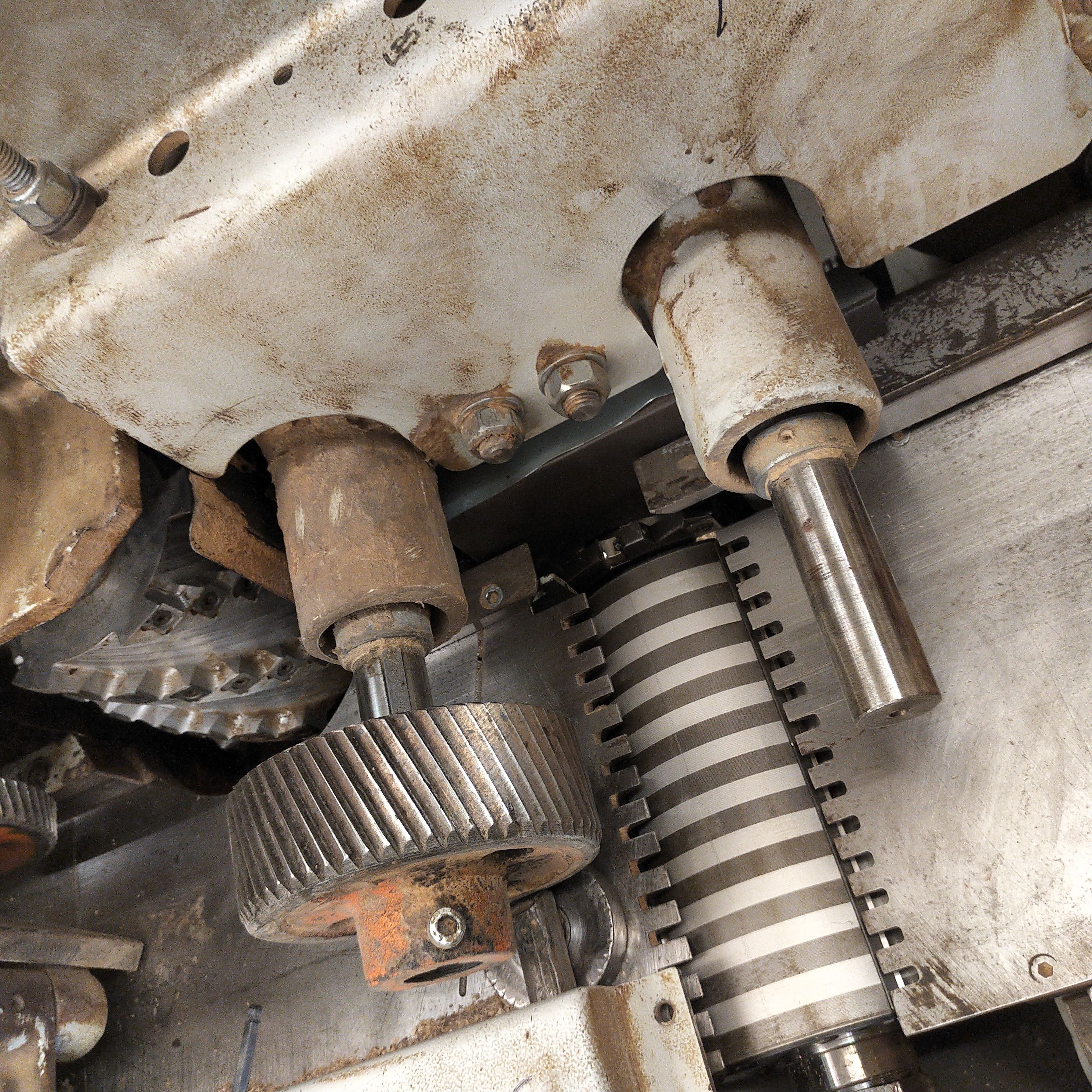

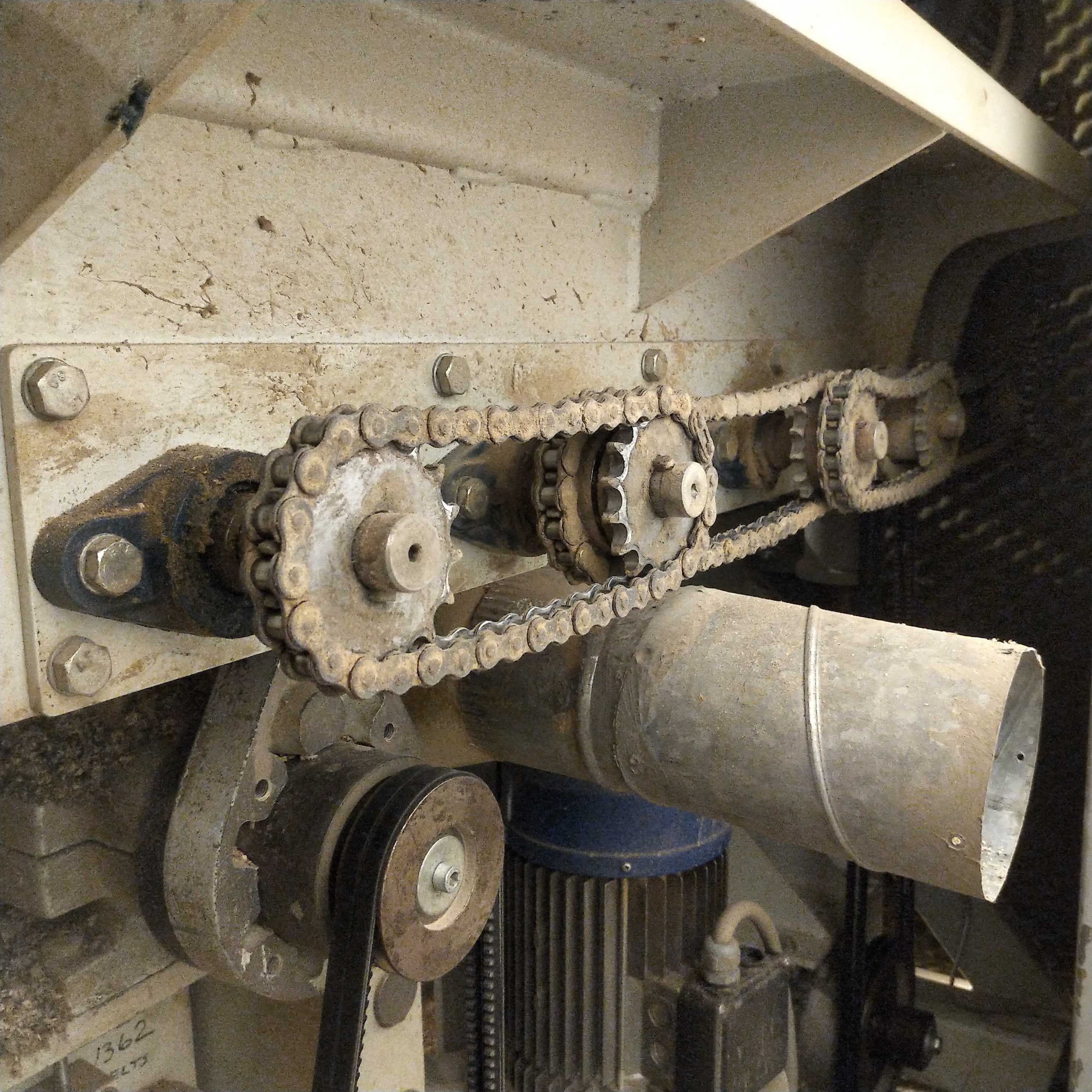

This has a chain drive for the pressure wheels, should the chains be tight or have some 'slack'? The feed seems slightly choppy as I keep a finger on the board as it goes in but that could be something else.a

2/3/22 #26: 4 head moulder problem ...

Dave

I have never seen a chain drive, that could be the issue especially if you feel its choppy.

Sorry I am no help on the chain drive maybe somebody else will chime in.

Russ

2/3/22 #27: 4 head moulder problem ...

This is what I mean by chain drive

View higher quality, full size image (2976 X 2976)

2/5/22 #28: 4 head moulder problem ...

Changed all the knives for genuine tersa knives on the jointer head. Remarkable difference in the quality of cut. I still get the very odd pattern that I'm showing in the picture but it's much shallower. I took off the other three cutter heads and rotated all the knives so that everything was sharp and I cleaned them very very well.

i ran this piece of cherry at 12mpm instead of the usual 6mpm and three sides are perfect. i think running at 6 was dlling the knives due to overheating. The pattern that you were seeing on the wood repeats two and a quarter inches. I highlighted it with white chalk.

very odd. I am thinking now that I have an oscillation in the joint or head perhaps something is loose. perhaps the bearings are pooched. or the chain drive is doing something.

Even though there is that slight Ripple on the bottom that it is so shallow that we can tolerate that and sand it out with our thickness sander once our parts are assembled.

any thing else i should be checking? with the main cutterhead running solo there is alot of vibration in the long infeed bed.

my gosh, so much time spent!

View higher quality, full size image (2976 X 2976)

View higher quality, full size image (2976 X 2976)

2/5/22 #29: 4 head moulder problem ...

This may seem like an odd question, has the machine been placed on leveling pads and is the machine level? The leveling bolts need to be on a leveling pad, not just the bolts touching the floor. Basic stuff that gets overlooked sometimes.

Those knife marks would drive me nuts.

Oh well if its good enough for you I guess my job here is done.

Thanks for allowing me to help (somewhat)

Russ @ MR

2/5/22 #30: 4 head moulder problem ...

I'm going to keep working on it to get rid of the knife marks. Drives me nuts as well and not up to my standards. I like things running perfect! Thanks for the help Russ! Much appreciated!

2/5/22 #31: 4 head moulder problem ...

I am going to re-level it tomorrow and check all the bolts and pads. We have 1/2" steel plates 3x3"

2/6/22 #32: 4 head moulder problem ...

Dave

I question weather a steel plate has the ability to absorb any vibration. Please read my article on leveling a profile grinder, same concept for a moulder. There are some pics of cast leveling pads and shock absorbers. You may want to review to see what you think.

All the best

Russ @ MR

https://www.mr-moulding-knives.com/information/profile-grinder-leveling

2/6/22 #33: 4 head moulder problem ...

Problem solved!! Out of balance pulley on main motor. Was shaking the whole machine.

View higher quality, full size image (2976 X 2976)

2/6/22 #34: 4 head moulder problem ...

Excellent Dave

Good sleuthing,

Its been real.

All the best

Russ @ MR

2/8/22 #35: 4 head moulder problem ...

Is this machine running v belts to the cutterheads? Maybe look at putting a segmented belt on to add some vibration reduction also. Nice find on the pulley!

|