Message Thread:

Should I consider CNC

3/15/19

Hey all!

I have a very small kitchen cabinet and refacing business. (200 doors/month and 50ish cabinets/month.)

We currently purchase all our doors and drawerboxes. We make our own cabinets and accessories, as well as do all the finishing ourselves.

My cabinet guy currently uses a panel saw and edgebander. I had him look into a local CNC shop to sub out a job to. He watched the process and said that he can cut up an entire kitchen in less than half the time it took the local CNC shop to process the same job.

My cabinet guy is 61 and likely going to want to slow down at some point, so I'm considering CNC to not have to "train" someone as heavily to operate and build cabinets as efficiently as my experienced cabinet guy.

Also, about half of my doors are the 1 piece mdf doors for paint.

Mainly curious about at what production level did other manufacturers decide to hop on the CNC bandwagon and was it worth it at that level.

Any advice is really appreciated. Thank you for your time.

3/15/19 #2: Should I consider CNC ...

The answer is yes.

Reasons to numerous to mention.

Maybe he could cut faster - after someone had made the cut list. He also couldn't edgeband and saw at the same time.

CNC means all parts perfectly square, all slide, hinge and shelf pin holes perfectly placed. All screw holes pre-drilled.

The right cabinet software means that MDF doors are spot on and all drawer sizes are calculated for you.

Cost savings on MDF doors.

Etc.

Etc.

3/15/19 #3: Should I consider CNC ...

Your dude is incorrect thinking he can process panel stock as quick as a cnc. I think I'm pretty decent at cut out, I'd average about 45 minutes a sheet from rack to stacked parts ready for assembly. 40 sheets would take about 30 hours. Cut, dado, linebore. That was with a Striebig, a cabinet saw, another cabinet saw for dados, so no tool changes. And a 50 hole double head linebore.

The cnc averages 5 minutes a sheet for me. Some more, some less. I spend about as much time unloading and loading as I do cutting.

Parts are handled twice. Load, unload.

Manually? At least 5-6 times. Rip, rip again, cross cut, dado a few times, linebore, stack.

My cnc has only been up and running about four months. It's been a game changer for me personally. I still work a bonkers amount of hours, but not like I used to. Parts are perfect, (so long as drawn correctly), it perfectly wrong... We've started doing some different joinery to make assembly easier and more accurate on the benches.

I wish I would've pulled the trigger much sooner, but I didn't have the capital or space. Hindsight, I would've prioritized acquiring a router much earlier in my career. I could funded all of the other things I bought first with a cnc and a bander.

It has it's downsides. It's a lot of money. The learning curve is steep and frustrating. When things start going well, it's a godsend.

3/15/19 #4: Should I consider CNC ...

Website: http://MCCWOODWORKING.COM

Website: http://MCCWOODWORKING.COM

I agree with the previous comments. I have had my CNC router since 2000 and it is the most productive, useful and versatile tool in my shop. You can do so much more than just cabinets.

However, you mention your "Cabinet guy." If you are not hands on and actively involved in running your shop, I don't know if this would be a good idea for you. I am self taught and there is a real learning curve in owning a CNC. I don't think a hourly employee could get a router up and running and productive. It sounds like your shop is not really doing that much volume.

3/16/19 #5: Should I consider CNC ...

Thank you for the responses.

My "cabinet guy" happens to be my father. For the past couple years i have been arguing with him over this cnc decision. He holds strong against cnc even after watching one cut up a job for us.

I used to be the "cabinet guy" until i hurt my back which then forced me into the spray booth. So i have operated the panel saw and edge bander for years. I also used to make all our 5 piece wood doors by hand too utilizing a few shapers.

So im more hands on then i let on in my previous post. Trying to convince my partner(cabinet guy/ father) is becoming ever more difficult.

In terms of an entry level cnc. What should i be looking at? I am really interested in making my own 1 piece mdf doors. Watched a video on a shopsabre. Seemed really neat. The gentleman in the video talked up the use of his machine utilizing "ball screws"? Vs "rack and pinion" basically eliminating all play whatsoever.

If im somehow able to convince my cabinet guy where should i start my cnc search? Should i consider used or only new? Given my lower production level, should i try to go with a smaller unit?

Again thank you so much for your advice everyone, i really appreciate it.

3/16/19 #6: Should I consider CNC ...

Website: http://MCCWOODWORKING.COM

Website: http://MCCWOODWORKING.COM

That gives us a different perspective. Your father is probably a smart guy, he has his son working with him, so he has done somethings right. My suggestion is to visit other shops, visit the companies that sell routers and manufacture the routers.

I think you will find cabinet shop owners will be helpful and many will share their knowledge. I own an AXYZ with an 80" x144" table and for me, this size is really important. I can do large countertops. It has a Digitizeing feature and it is easy to trace a template. I had it set up with two drill heads. One drill is set up with a 5mm bit and the other is set up with an 8mm bit. I do not have tool changer. At the time I bought my router, I thought their tool changer was too slow.

I would recommend you look at new. The support you get from the manufacturer and technical support is really valuable and you will be getting the most updated technology.

If you are going to be in the business, you have to make the move. Once your father sees how versatile these routers are, he will love it. Kevin Hasslett, he is the Chairman of the Presidents Consel of Economic Advisors said "Every time there is a Capital Investment, there is an increase in productivity and wages." I think he is correct. But, you are going to have to be the guy that learns the CAD programs and a lot more.

3/16/19 #7: Should I consider CNC ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

It is rare But i prefer competing with a shop that does not have a CNC ! LOL

View higher quality, full size image (1600 X 1064)

3/16/19 #8: Should I consider CNC ...

There is no way that anyone can cut and completely process a sheet as fast as a good CNC. You might be able to cut your parts but thats it. When a sheet comes off our CNC everything is done and all our cabinets are built with blind dados. This makes cabinet assembly so much faster. All shelf holes are drilled. All hardware holes are drilled for drawer runners and hinge plates. It is so much easier to be able to mount hardware when your parts are laying flat on your table. If all you are going to do is cut parts then its not worth it. You have to learn a good software like mozaik and make the cnc do EVERYTHING it can do to improve all other processes through your shop. MDF doors are easy but it takes several tools to do different profiles. A 4x8 sheet of shaker doors takes us 30-45 to run but you can be doing something else during that time. You don't have to stand there and watch it. A 4x8 sheet of cabinet parts takes about 5-10 minutes depending on the number of dados and shelf holes and extra machining. The actual cutting of the parts is very fast. The key is in the software. If you don't learn good software then a cnc will not make you any money.

I would look into camaster cnc a 4x8 is good a 5x10 is nice if you ever do any odd panels. A tool changer is a must for what you are wanting to do!! I run 4 tools for a shaker door. An 1 1/2" dado bit to hog out the panel then 1/2" to round the corners better then 1/8" to make good tight corners. Then lastly 3/8" to cut the parts. I would also get a drill bank if you can afford it. Expect to spend $2,000-$3,000 on tooling to do everything you are wanting to do.

I will be happy to answer any more questions but buying a cnc was the best thing our shop ever did!

3/16/19 #9: Should I consider CNC ...

This is great info everyone! Thank you for the input.

I used to do a little programming work in school (c++ and something else I can't remember. - meaning I enjoy the computer side to things as much as the hands on woodwork.)

I think I need to widen my "eyes" in terms of operations the CNC can do for us. I hadn't thought about all the consolidation of tasks that you guys outline. You're correct that we do perform all these tasks separately right now. The parts are cut then banded then line bored then assembled then hardware installed (via handheld jigs etc.)

Having the pre-drilled holes for the hardware sounds amazing!

We're in the process of building a new shop and I'm wondering if I should try to get extra financing to add a CNC to our shop.

Besides the generic tasks that I'm thinking of like cutting and milling cabinet parts and mdf doors, what are other out of the box operations you guys have done with your cnc's?

Like I said, i think my scope is still too small. If I can widen the possibilities I might be able to explain this decision better.

I'll look into that Cammaster that you said.

Thanks again everyone!

3/16/19 #10: Should I consider CNC ...

Definitely look at it real hard.

Do some math on your doors purchases versus producing in house and the decision should be a no brainer.

3/16/19 #11: Should I consider CNC ...

Gonna have to use a three year or four cash flow projection and history to justify.

I will say, you will never look back.

I have 6 seats of CabinetVision and 2 s2m centers. Getting ready to add another. I just hired another drafter. I have 2 cncs running all the time.

And, I could cut, dowel, band and bore faster than your dad. But, not consistently and by Weds my back would hurt and after 200 sheets, well - screw it.

Software. Dust collection, dry air and good space. Standards.

I have more money in compressors than most do in their cnc. Itís not cheap in all aspects, but if you have a bander, go for it.

Please get a tool changer, HSD spindle and boring head. Closets can open up many doors.

PM me if you need some help. I have serious iron, you most likely wonít need what I have but we run at least 130 sheets of melamine a week easy along with corian.

There are some very important features you must look for including vacuum.

Call Jack Lim at Limtech or the guys at Shop Sabre. Jack will not steer you wrong and help you choose well and keep you on budget. Catallay might be a good choice too. They have been around a long time.

3/17/19 #12: Should I consider CNC ...

The closer for me a long time ago:

A router payment will cost you 1.5 a month or so

Or you can have an almost minimum wage worker for the same amount...

3/17/19 #13: Should I consider CNC ...

That's the other thing. What do you think im looking at in terms of shipping, delivery, and extra misc costs above and beyond the base price of the cnc?

3/17/19 #14: Should I consider CNC ...

It all depends on what dust collection you have now and what compressor you have. You need good dust collection and clean dry air. Our wiring bill was about 3k, we have added tooling a little at a time but spent 2k when we bought the cnc. See if you can get delivery included in the price then you can finance that. Depending on the size of the machine you may need rigging or atleast a forklift to get it in place. I would finance the cnc separate from the building but maybe get some extra money for things like tooling and wiring and dust piping.

3/17/19 #15: Should I consider CNC ...

Lots of good advice, years ago I learned to build cabinets but using a sliding saw, I would cut the parts, then edgeband, install all the hardware manually like you said. I thought I was fast on the sliding saw, but when I bought a cnc and watched it cut 12 top/bottoms in 2 1/2 minutes I was wow.

Then when it cut the gables and did all the drilling for the hardware, that was impressive, and the time saving and mistakes were cut by a mile.

I firmly believe you need a cnc to compete now days.

Cncís are just like any other tool or even a delivery truck. If you just haul small items you donít need a Kenworth with a 53 ft trailer, the same applies with a cnc.

If your a small shop you donít need anything extravagant. You donít need big iron, you certainly donít need big compressors and you definitely donít need a 40 hp vacuum. There are lots of machines that are 4x8 table, with 10 hp vacuum and your regular shop compressor and dryer are fine. You however do require a decent dust collector and decent software is a must, depending on what you do exactly. If you build the same 10 things over and over you donít even need that. If I had to I could write the gcode for a standard kitchen in no time.

The only other advice I would give is buy a machine with good support and service. It gets frustrating if it is broke down and you have to start using the saw again.

3/21/19 #16: Should I consider CNC ...

All the previous advice is spot-on. I don't care how good he is, there's no way he can process sheets as fast and accurate as any CNC.

If you are not currently designing with software, be prepared for an even larger learning curve. One thing I did was pop for the software and learn to use that for a year or 2 before making the machine purchase. That way I spaced my investments out, and more importantly I spaced my headaches out. Each one is a large learning curve. I also got to understand how the software worked which helped me make better decisions on what we needed for the machine. You will change your way of building to suit the machine. It won't be less quality, it will just be different. Your father won't like that, but change is inevitable and he'll get used to it.

My wife was very against my going into debt to purchase the machine. After it was up and running and I was pulling in 4x as much work, she agreed that it was a very wise decision and that I was right to go against her wishes. I wrote that one down and am saving it!

3/21/19 #17: Should I consider CNC ...

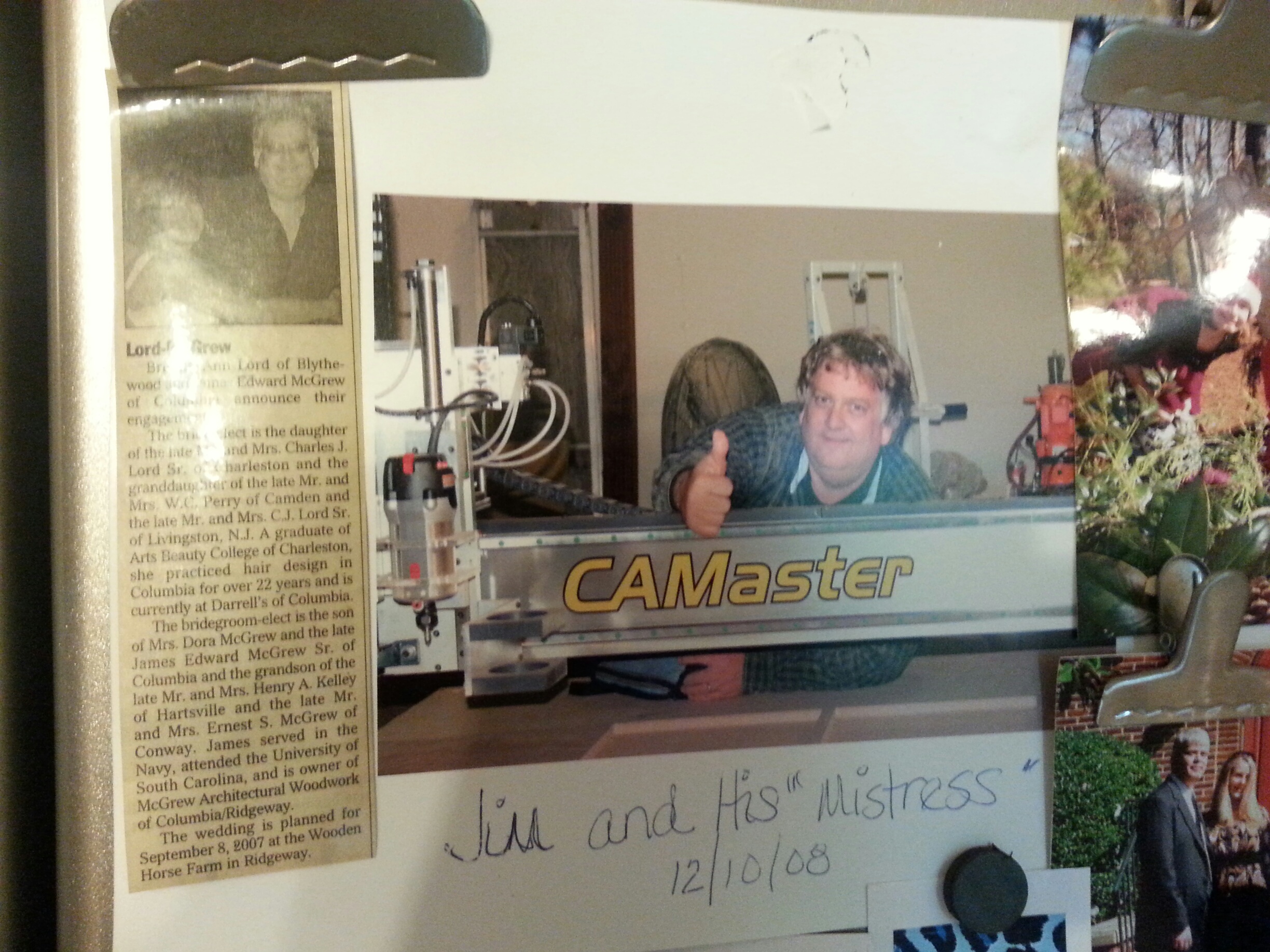

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

Speaking of Wives ! I got married on Sept 9 2007 I bought my first CNC in November 2007, This photo has been on the refridgerator ever since

View higher quality, full size image (2448 X 1836)

3/25/19 #18: Should I consider CNC ...

Website: http://closetdr.com

Website: http://closetdr.com

Yes, by all means you should be considering a CNC.

1. its cheaper and more reliable than an employee. It doesn't have car problems, it doesn't have substance abuse problems, it doesn't have a crazy girl friend or any of those things. My payment is $2200 a month. An entry level employee costs me about $3k a month.

2. Your partner/dad/lead cabinet guy is a young 61. While I admire his swagger that he can do it faster than a CNC, and maybe he can but I doubt it, whats your plan if he gets injured/ decides to call it a day etc? A CNC isn't necessarily plug and play, but once set up with a proper software program, can be run with minimal supervision with a lesser skilled employee. (Believe me, I've had some really lesser skilled people on mine). Additionally assembly is simplified, no jigs, no drilling no secondary machining. Assembly can be performed by lesser skilled employees as well.

3. As mentioned before, the operator isn't working on it 100% of the time. while its working other tasks are being completed, our edgebander is 10' away from end of offload conveyor, so operator unloads and edgbands material. From a material handling standpoint this eliminates the batch processing of materials that happens with a saw, you don't end up with huge stacks of material that you have to move and then recreate that stack at the edge of the bander and sort to other secondary machines. Every 3-10 minutes a sheet of parts rolls off the table and a new sheet starts. While its running those 10-20 parts are banded and banding finishes up about the time the next sheet rolls off giving you a nice smooth flow.

4. Buy a reputable machine. I'm a Raving fan of Biesse. I'm on my second CNC and second edgbander with them and their service has been amazing. First we rarely need it. Second, when we do they are there. Important thing about support, make sure your company has several and not just one guy, cause when he is on vacation hunting wild pigs, your machine is down until he gets back! (True Story).

5. Machine wise, buy all you can afford. I have RoverS auto load/unload and run 80-120 sheets a week regularly but have run 60 sheet days. I cheaped out on the auto label set up but won't make that mistake again. You probably don't need that much, but I would suggest a push off rake at a bare minimum. You will need good dust collection and a scissor lift as well. I ran my first unit with a 6.5hp compressor from sams club for 13 years, I had a dryer on it.

5. Software, this is where the real learning curve is. We run Cabinet Vision and I have a dedicated guy that has done my set up. I'm not a software guy. Biesse has a new software that they can include that is a full nesting system. You want a program that eliminates the need to program specific tasks. I can design a job from my set up catalog and in less than 5 minutes be running parts at the CNC. Tool comp, dado widths, line boring finished end, unfinished end, it all happens automatically. We never program at machine, we just open work lists and go.

Good luck and have fun.

3/29/19 #19: Should I consider CNC ...

I asked the same question a little over a year ago and many of the commenters on here led me in the right direction. One thing that I donít think has been mentioned is optimization, you just simply canít get as many parts out of a sheet on a table saw as you can with a CNC. So it takes less sheet goods and thereís not as much waste. Everyone else has hit all the major points of the benefits so Iíll not repeat them but they are correct. Another benefit is youíre not limited to cutting sheet goods. Iíve been cutting fluted columns, valances, arches, heat vents, and other things. Get a tool changer for sure, you wonít regret it, the more holders the better.

As far as your dad, I too went to a shop that had a cnc and watch it cut cabinet parts and thought, well Iím faster than that thing, but someone on here explained to me that while it was cutting parts then I was off doing something else. And pushing sheets back and forth through a saw all day eventually gets to the back. Now all I do is pull a sheet off a cart onto the machine and run it. A cnc is a game changer. Itís an expert woodworker that never complains or calls in sick.

I have a Camaster and use Mozaik and vcarve software.

7/11/21 #20: Should I consider CNC ...

Website: https://forsuncnc.com/

Website: https://forsuncnc.com/

Judging from the current market situation, all cabinet and furniture manufacturers can benefit from CNC woodworking engraving machines. The occasional readings of traditional woodworking in terms of processing speed and accuracy can no longer meet the growing needs of the woodworking industry. CNC woodworking engraving machine is more efficient. At the same time, the product has high flexibility and can be customized according to the actual needs of different consumer classes. Buying a CNC router machine may be a good way.

|