Your dude is incorrect thinking he can process panel stock as quick as a cnc. I think I'm pretty decent at cut out, I'd average about 45 minutes a sheet from rack to stacked parts ready for assembly. 40 sheets would take about 30 hours. Cut, dado, linebore. That was with a Striebig, a cabinet saw, another cabinet saw for dados, so no tool changes. And a 50 hole double head linebore.

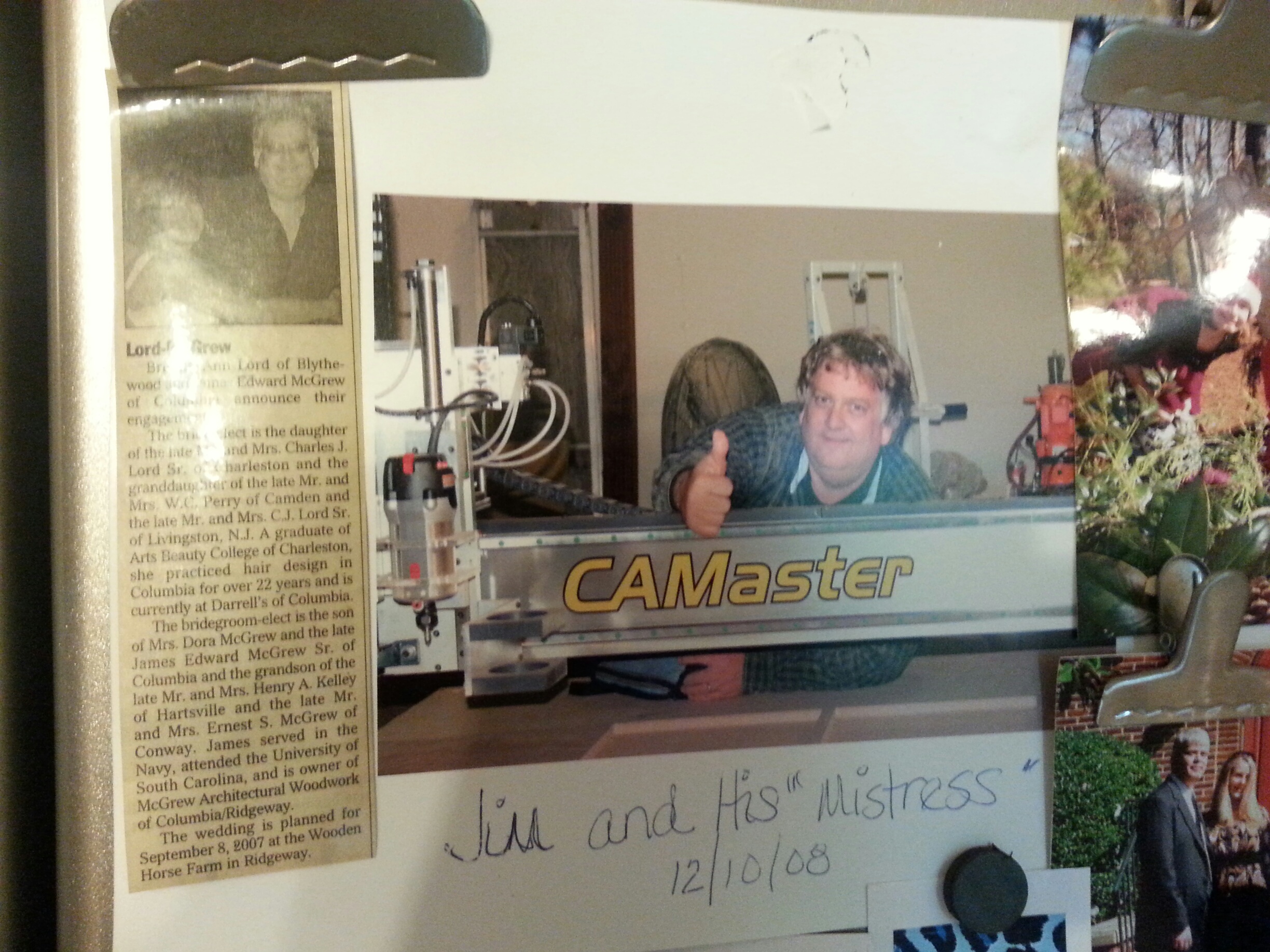

The cnc averages 5 minutes a sheet for me. Some more, some less. I spend about as much time unloading and loading as I do cutting.

Parts are handled twice. Load, unload.

Manually? At least 5-6 times. Rip, rip again, cross cut, dado a few times, linebore, stack.

My cnc has only been up and running about four months. It's been a game changer for me personally. I still work a bonkers amount of hours, but not like I used to. Parts are perfect, (so long as drawn correctly), it perfectly wrong... We've started doing some different joinery to make assembly easier and more accurate on the benches.

I wish I would've pulled the trigger much sooner, but I didn't have the capital or space. Hindsight, I would've prioritized acquiring a router much earlier in my career. I could funded all of the other things I bought first with a cnc and a bander.

It has it's downsides. It's a lot of money. The learning curve is steep and frustrating. When things start going well, it's a godsend.