Message Thread:

Paint creep through internal grain lines

3/30/25

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Hey all. Wonder if someone can give me a suggestion to resolve this minor problem.

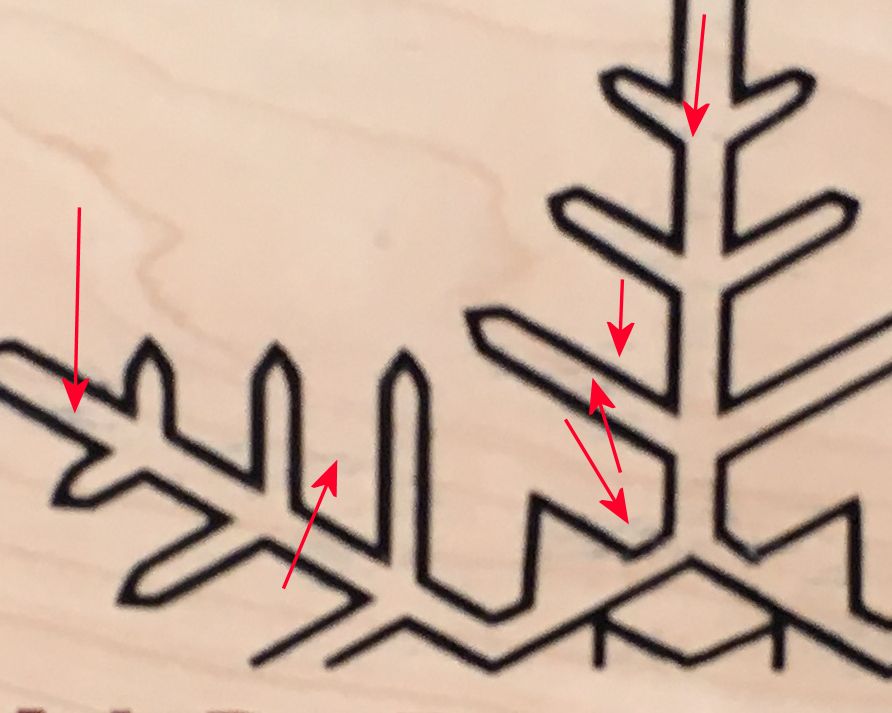

I'm carving signs on the CNC with a 60° V-bit. The cut is about 1/16" wide x perhaps 3/32" deep. I'm cutting through a Oracal Oramask paint mask. All is going very well with the exception of some very fine thread like bleeding that is taking place through inner grain layers and up to the surface.

The material is pre-finished 1/2" maple plywood.

I carve the signs and then apply 2 coats of clear shellac into the V-groove carved lines. Without the shellac sealant the black paint creep through the grain and up under the pre-finished surface is severe. The 2 coats of shellac reduce it by about 90% but don't eliminate it. I've tried both brushed on shellac from the can and spray on from a rattle can. Both give similar results.

These bleed lines may emanate right from the edge of the cut or might jump 1/8" or so away from the carved cut and jump up to the surface out there. The only logical explanation is that the paint is finding fine pathways through the plywood core grain and coming up below the clear finished surface.

Finish paint is Krylon Fusion from rattle cans. That's a bit costly but there is adequate money in these repeat signs to justify the cost. The thinness of the paint is also a logical explanation of the bleed out occurring. I've found though that it is the best product for both speed and mask removal as latex paints can tend to peel out of the cut with mask removal on these tiny v-cut grooves. The idea was that the 2 coats of shellac would seal these grain pores and stop the bleed creep. I've thinned the shellac from the can about 10% and of course sprayed it directly as it comes out of the rattle can. It has helped a lot but not 100% resolved the issue.

As these are you have to look close to see the thread like creep lines so the signs are acceptable to the customer. I would like to resolve this completely though.

I will point out that one has to be careful on what paints to use on the Oramask. While Krylon Fusion colors work quite well (even though Oramask is spec'd for Acrylic paints) the Fusion clear finish will creep under the mask and cause separation. As such I really can't use that as vs. shellac. Surprisingly the Zinser clear shellac causes no problems here.

Any suggestions will be appreciated.

Thanks,

BH Davis

View higher quality, full size image (892 X 713)

3/31/25 #3: Paint creep through internal grain ...

The photo is a bit blurry to see the bleed but I know what you are talking about. I don't think you will ever get a full seal with shellac in the ply substrate. The cracks from the thick rotary veneer are just too big. I think you could change how you apply the black though. Still apply the shellac sealer but then try to spray a very dry coat of black. It is not easy with cans an air brush would be better. Many dry coats to get full colour.

3/31/25 #4: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

I came out to the shop the morning and got a better photo.

BH

View higher quality, full size image (4032 X 3024)

3/31/25 #5: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Thanks Tom. Given your thoughts I'm trying one more thing with shellac this morning. I've rolled on 2 coats with a 4" roller, totally flooding the V-carved grooves right up to the top.

They're actually more like just under 1/8" wide by just over 1/8" deep, so the wells are able to hold a fair amount of shellac that then will hopefully soak back into the grain pores. This is from the gallon can and I'm rolling it at full viscosity.

I'll post the results later.

BH Davis

3/31/25 #6: Paint creep through internal grain ...

My only thought would be to not use the can shellac. Mix your own from de waxed flakes to get a thicker consistency. Might fill the pores/seal faster than flooding with the thin can stuff.

4/1/25 #7: Paint creep through internal grain ...

Use a black paint that is comprised more of pigments and not dyes. It's the dyes that are creeping into the grain pores.

Have you tried a black primer, then a black paint?

4/2/25 #8: Paint creep through internal grain ...

Do you think the paint might be getting between the prefinished film layer and the plywood? Maybe that finish is brittle or not bonded well?

4/2/25 #9: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Good thoughts. I'll see what I can find for a base coat that doesn't affect the Oramask adhesive.

I've completed the current group so this won't happen for several months now. The double coat of rolled on full strength shellac improved the situation dramatically but not 100%.

Thanks for the ideas everyone. This has been a strange problem.

BH Davis

4/2/25 #10: Paint creep through internal grain ...

I've been finishing my local brewery's (Caldera Brewery Ashland Or.) wood tap handles for at least the last 10 years. At first we were using Ash cuts from Sawyer's oars until we needed more than they could provide so we started using Maple when the ash ran out.

The process we ran was;

Woodworker makes the handle

I finish with 3 coats of 2k WB poly

Then the engraver takes over; masking, laser engraving, painting black on the engraved surface.

On the first run with the maple the black paint looked to be weeping up under the masking but in reality one of the local wood turners pointed that the paint was being drawn up in tiny voids or straws that are present in maple. So we quit using the maple and went back to ash, problem solved.

4/2/25 #11: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Thanks Nick. That is very interesting.

BH Davis

4/2/25 #12: Paint creep through internal grain ...

Website: http://cherrybrookwoodworks.com

Website: http://cherrybrookwoodworks.com

I would try spraying a sanding sealer first. Or mist the black on with a primer first. You would need something that sprays better than a can to mist it. You could also try a water based, clear, grain filler. I also wonder if thinned down hide glue would seal the grain.

4/2/25 #13: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

I like the idea of the thinned down glue. Perhaps Titebond and then a coat of shellac on top of that for adhesion.

BH Davis

4/2/25 #14: Paint creep through internal grain ...

Interesting that maple drew in the paint worse than ash. I guess this is the power of capillary action. I presumed the larger the pore the worde the problem but it seems the opposite is true.

The only time I did black engraved graphics in wood was for a dining table. I v carved the female and cut the infill from Colorcore Formica. Then I painstakingly spread pva with a toothpick and pressed each formica letter in place. The outcome was good but I only did it once for a reason.

4/2/25 #15: Paint creep through internal grain ...

Website: http://cherrybrookwoodworks.com

Website: http://cherrybrookwoodworks.com

I doubt the maple is absorbing the color. It is most likely a poplar cross band below the maple that is absorbing it. Not knowing the plywood type, the poplar is a guess at best. With my suggestion on sealing it with hide glue- Id probably do a quick sample of mixing hide glue and then titebond, both thinned, on a flat surface, and see how well the paint sticks to both. I would lean toward using thinned hide over titebond but dont have a solid reason for that. I do think bw the glue, sanding sealer, or a thinned spray coat of primer, you will get it figured out.

4/7/25 #16: Paint creep through internal grain ...

I will be the obnoxious voice and say, simply, that wood is exhibiting one of its properties here, and the paint is wicking up the “grain” or vesicles of the Maple. Gee whiz, guys…..

‘Tis its nature, you see. I think any wood is likely to do it, though some more, others less than what you now have. While I support the use of our favorite material, if a change of species and technique does not remedy your dilemma, a different, non wood, material may be called for.

Upon a second cup of coffee, a ply of Wenge, with Maple on top will avoid all this business with shellac and such. While wood is often the problem, it is often the solution as well.

4/7/25 #17: Paint creep through internal grain ...

I think you should just go back to drinking your coffee. The sarcasm isnt really needed.

4/7/25 #18: Paint creep through internal grain ...

Starbucks -

“Lost in the wash of life” As a friend said this morning about problems we all face from time to time.

“While wood is often the problem, it is often the solution as well.“. Is suitable for framing. No sarcasm, sometimes I surprise myself. I hope you do the same. Two phrases that have bearing on life/work/wood this morning.

I spent my life selling wood as the solution and solved things for thousands of people. I did make mistakes, but the wonderful material wood is, I could overcome any problem. Wood is the solution. Literally and figuratively.

And I will bet lunch that the wenge layer under Maple will work just fine. 1/2” pre finished maple ply it ain’t, but it will not bleed like the various liquids mentioned.

Bernie - My apologies for hijacking your thread with my ramblings.

4/16/25 #19: Paint creep through internal grain ...

Maybe you could paint it with the Krylon in a color close to the wood color first. Some sort of tan? Then any wicking would be closer to the wood color. Topcoat with the black last. Just a thought.

4/16/25 #20: Paint creep through internal grain ...

Website: http://www.bhdavis.net

Website: http://www.bhdavis.net

Wyatt,

Actually a good thought. That was the idea of trying the Krylon clear first. However not all the Krylon Fusion colors are the same chemical make up. Some, like the clear, react with the Oramask adhesive and make the edges peel. The Ormask adhesive is designed for acrylic based paints. It's rather amazing any of the Fusion paints work with it. But trying a tan is a good thought. Certainly worth a shot.

BH Davis

4/28/25 #21: Paint creep through internal grain ...

Website: http://www.bergenfurniturenj.com/

Website: http://www.bergenfurniturenj.com/

It sounds like you've tried some solid solutions, but there are a few more things you can try to eliminate the paint bleed. First, consider using a thicker, higher-viscosity paint, which will reduce the tendency to seep into the grain. You might also try using a wood grain filler or sealant in the grooves before applying the paint. This can help to fill the microscopic gaps in the grain and prevent the paint from bleeding through. Additionally, applying a heavier coat of shellac and allowing it to fully cure before painting may help seal the wood more effectively. Another option is to experiment with a light sanding between coats of shellac to smooth the surface before applying the next layer. Lastly, make sure your paint is applied in thin, even layers, as multiple thin coats can help reduce bleeding compared to one thick coat.

|