Shaper w/ tenon tooling vs Single End Tenoner

5/19/23

I have a T130NPS , cast slider. I have opportunity to buy a Heian tenoner. A heavy Japanese make.

With all the newer options for shaper tooling I am unsure if a tenoner has a huge advantage over a sliding spindle moulder.

I am open to having my mind changed on that. I have never used a tenoner. The T130 does a pretty good job.

The things I do not like in regardless to shaper tenoning is it seems there requires a fair bit of force to push the part thru when making relatively deep cuts. 3"+. It not surprising as its a lot of wood.

I am assuming, (uhoh) that because the cheeks are cross grain cut, there is a substantial reduction in effort to push the part thru.

My shop is small, 2400 sqft. I do like the shaper because it can do more than just cut tenons. But I DO like old Japanese cast machines lol. And might make some space for it if a consensus might show that there are some real advantages to owning a dedicated tenoner.

Thanks for any thoughts or insights in to this.

5/22/23 #2: Shaper w/ tenon tooling vs Single E ...

A tenoner has several advantages. It will have a heavier table to carry the parts. The heavier table will be larger to do angled parts. The fence will be heavier, as will the clamping.

Some tenoners have two horizontal heads for sizing the tenon, and then two vertical spindles for the copes.

I had a T130 with a bolt-on tenon table. It had good bearings and a firm action, but was too small to ever get much use in our shop. We used a Powermatic 2-A two spindle tenoner to rough size the tenons, and final sized and coped on the Scmi, with a shop made aluminum sled. I finally bought a dedicated tenoner, but it is not hooked up yet.

5/22/23 #3: Shaper w/ tenon tooling vs Single E ...

Hi Dave thanks for your thoughts. The intergrated t130 table is pretty stout for sure. I have the tenoning plate that raises the table about 30mm. But as you say mitered tenons doesn't fit the table well. I have been just using the miter gauge directly on the sliding table for that. Mitered are a bit of humbg because you need to flip heads and fence to do the opposing end. Way too much set up for my taste. Not that it seems it would be different on a tenoner.

The T130 will do entry door size rails fine enough.

I guess my recent revelation is that most people are using 2 sets ups to cut tenons. Like you offer that you rough them out then cut to dimension. This is what I want to avoid.

I have been cutting shoulders on the slide saw, then cheeks on the T130. My grooving tooling I use for tenons doesn't produce the clean shoulder that a cross cut blade can produce. I suppose I could rough the cheeks on the bandsaw.

What tooling are you using on the T130? I might be better off investing in better tooling and an outrigger table with support arm than a tenoner.

5/22/23 #4: Shaper w/ tenon tooling vs Single E ...

We are using tenon and cope discs at about 8” diameter for max tenon length of 3”. We can do 1-3/4” thick rails in one go. It is the 2-1/4” thick that are just too much for the shaper to do in one pass. I suspect it is the weight of the discs that factors into ability; they are are heavy. Spindles on the large OD machines are 2” or mm equal, giving rigidity to those discs.

That is another benefit of a tenoner with large capacity discs or separate cope spindles - longer tenons. Aluminum discs also help fight the weight battle. I have never had a failure of any M&T joint at or about 3” long, but then, I may not have gotten a call.

View higher quality, full size image (4032 X 3024)

5/24/23 #5: Shaper w/ tenon tooling vs Single E ...

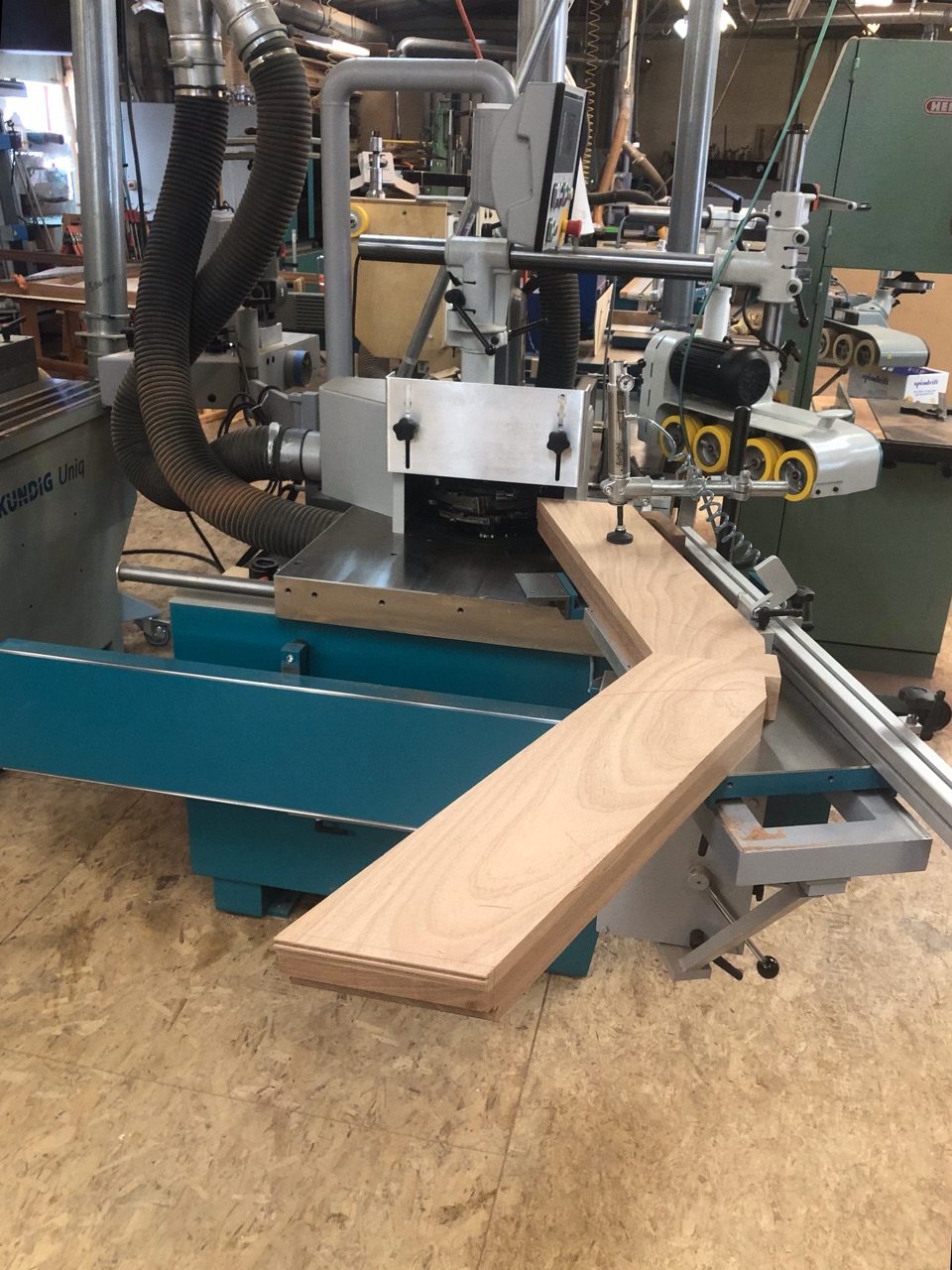

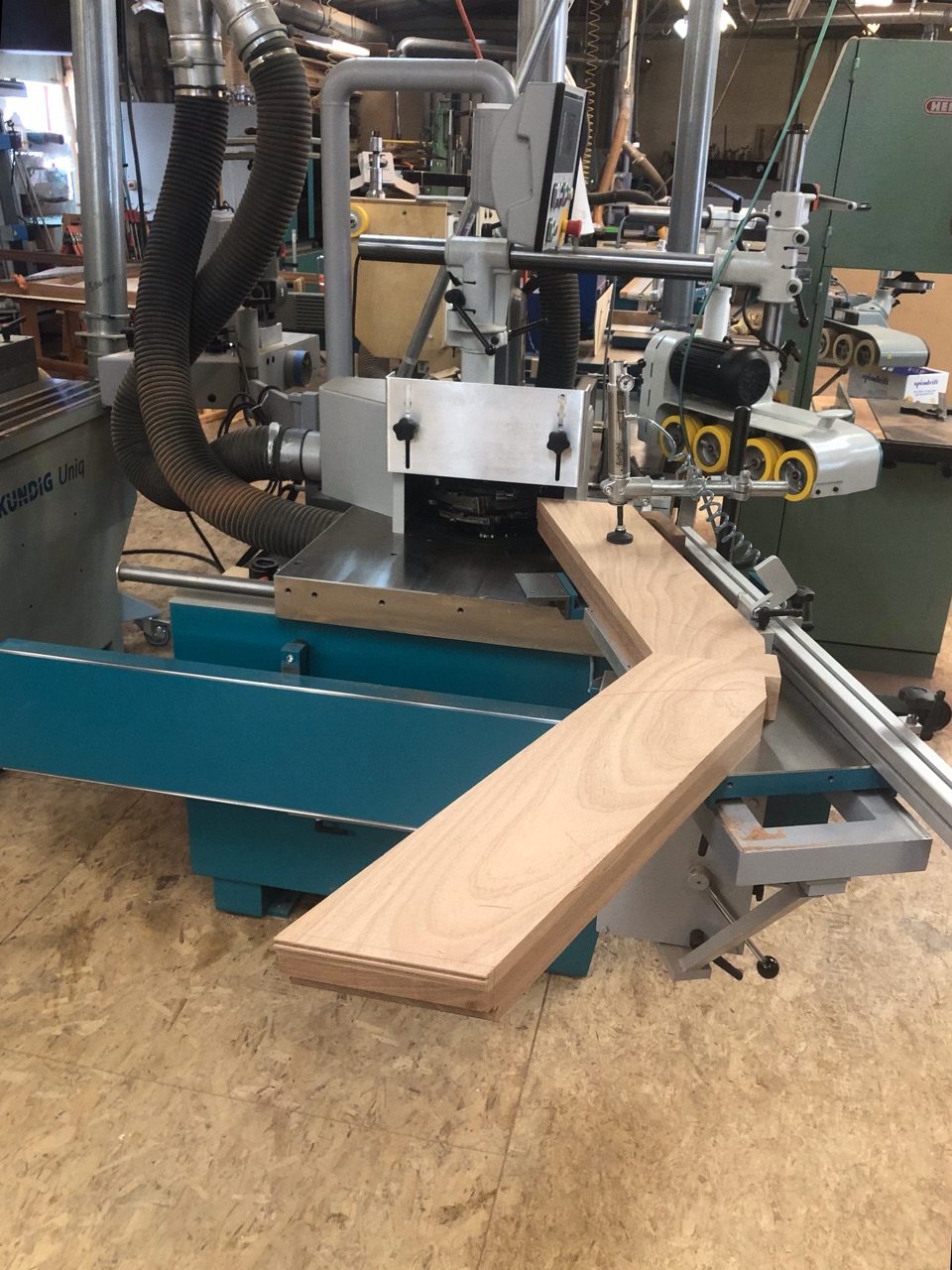

Correy, I have quite a bit of experience using shapers for tenoning and also European tenoners that are a little different than old iron US tenoners in that they usually don’t have the horizontal heads. I think the biggest advantage a tenoner with horizontal heads has is the ability to do long tenons. With my 320mm diameter disks I can do about 4 1/4” deep tenons which is usually enough.

Those Heian tenoners are my favorite of the old iron machines and would buy one myself if the right deal came up. Wadkin would be my second choice. I would leave it setup for square edge tenon work and not bother with the cope spindles.

Tenoning on shapers with the large disks is better done on the side mount table type. I had a few in table sliding shapers and never cared much for them. The side mount tables will take quite a bit of weight. I have a Panhans bolt on sliding table and find that one works well also. Its limitations are long lengths.

If you tenon on shapers you would be better off to buy European manufactured tooling. They have been doing this for many years on shapers and tenoners and the tooling is designed for it. It’s costly though and an old Iron tenoner will be less expensive to tool up but the setup and change over will be more labor intensive. Depends a lot on what you make.

I don’t have any trouble cutting tenons in one pass for windows and most doors. The exception would be wide white oak door rails on the vintage Martin shaper that is only 6 1/2 hp. The 10 and 13 hp shapers do just fine in all materials.

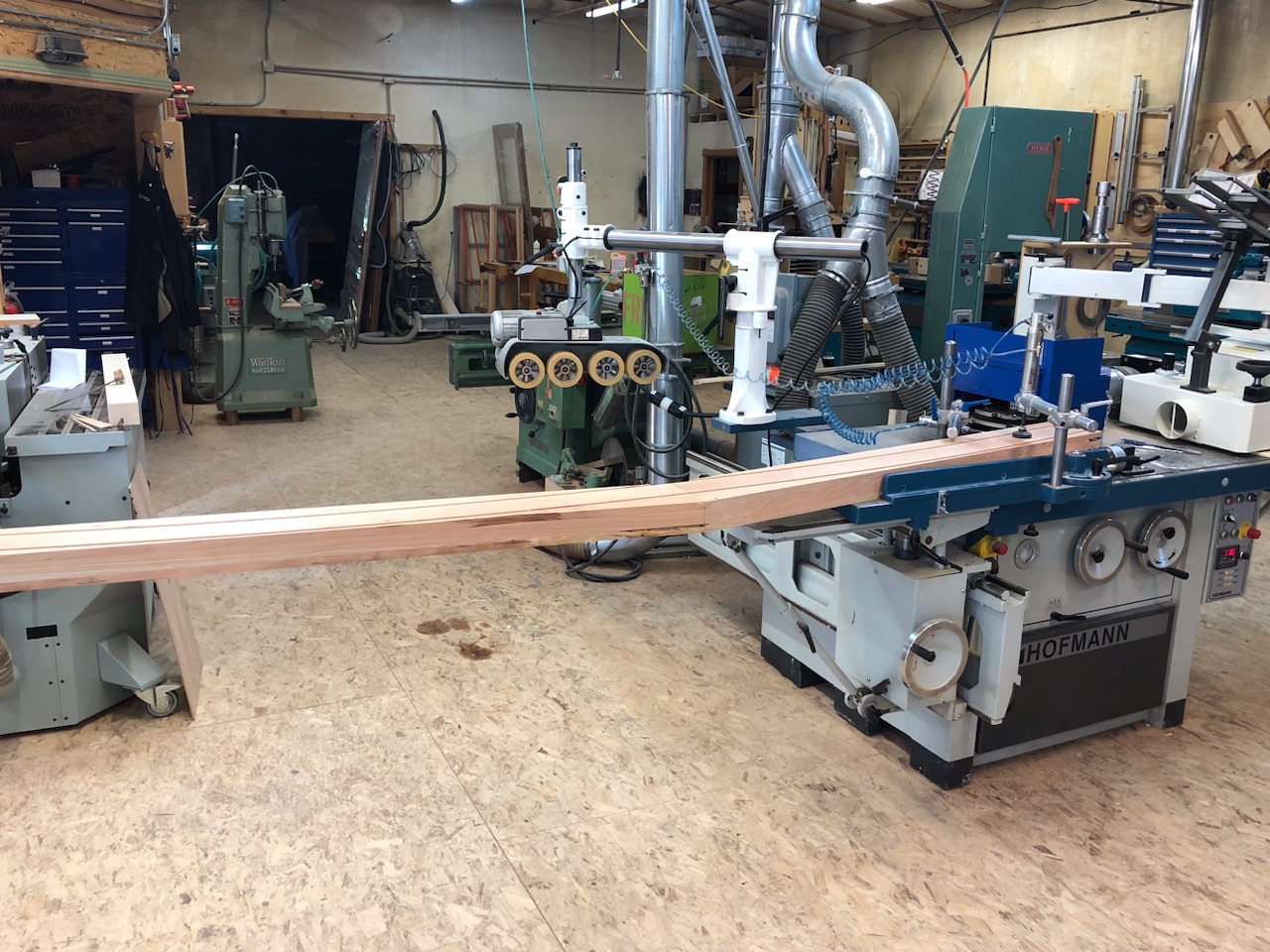

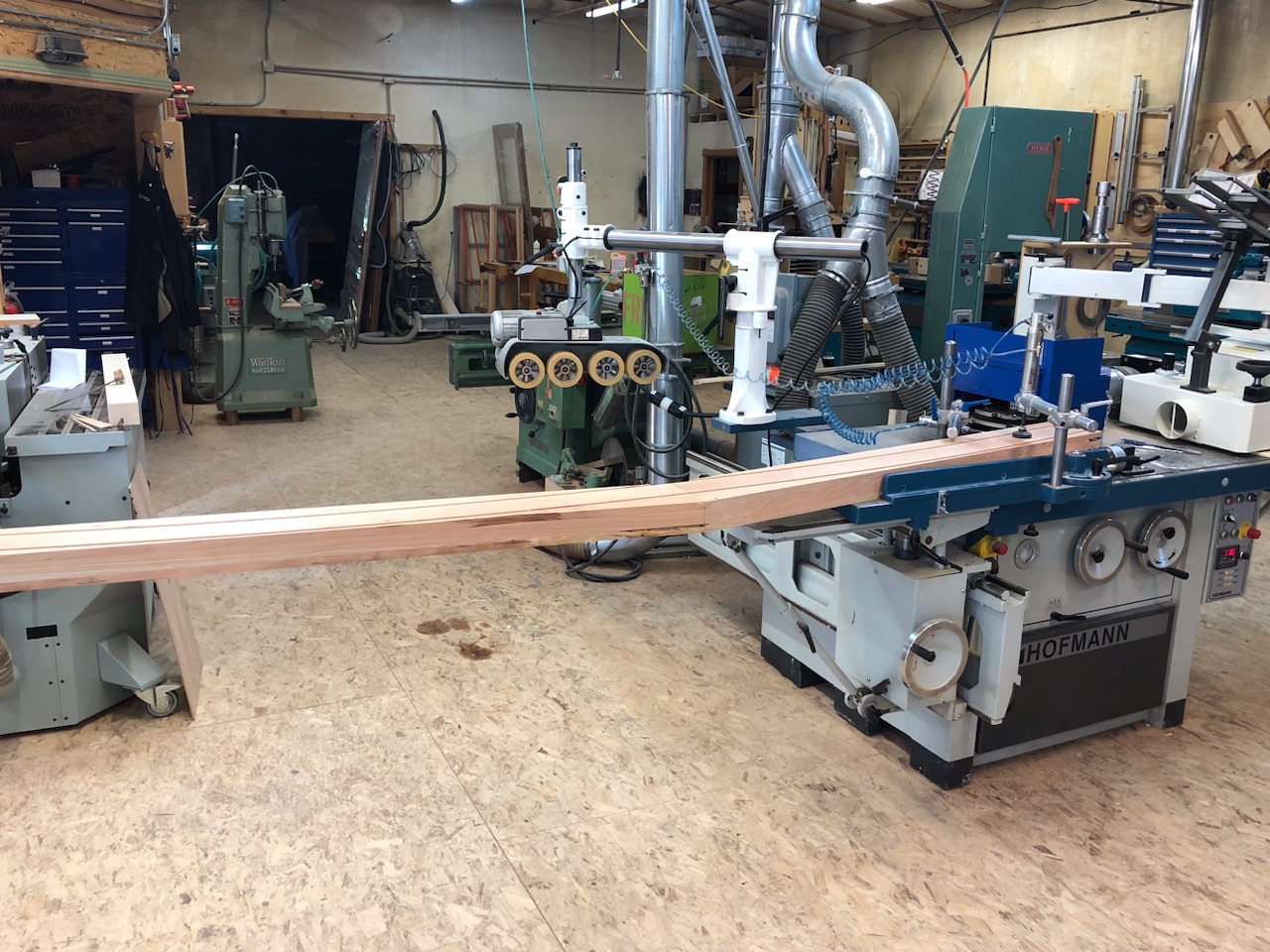

For angle cuts the newer Martin sliding tables tilt both directions past 60 degrees. The Hofmann and Vintage Martin will go both ways to 45 but awkward to set in the opposite direction. You will definitely feel back pressure going against the grain tenoning on a shaper. The Soukup CNC tenoner was pretty slick for angle tenoning and slotting with length compensation built in to the controller.

View higher quality, full size image (1280 X 960)

View higher quality, full size image (960 X 1280)

View higher quality, full size image (1280 X 960)